Internal and external dual-spiral-flow centrifugal separation type heat exchanger

A centrifugal separation and double-helix technology, applied in the direction of heat exchangers, indirect heat exchangers, heat exchange equipment, etc., can solve the problem that the medium cannot achieve sufficient heat exchange, the heat exchange temperature difference between cold and hot media is small, and the heat exchange area is small Advanced problems, to achieve the effect of reducing safety, increasing heat transfer temperature difference and heat transfer area, and improving heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

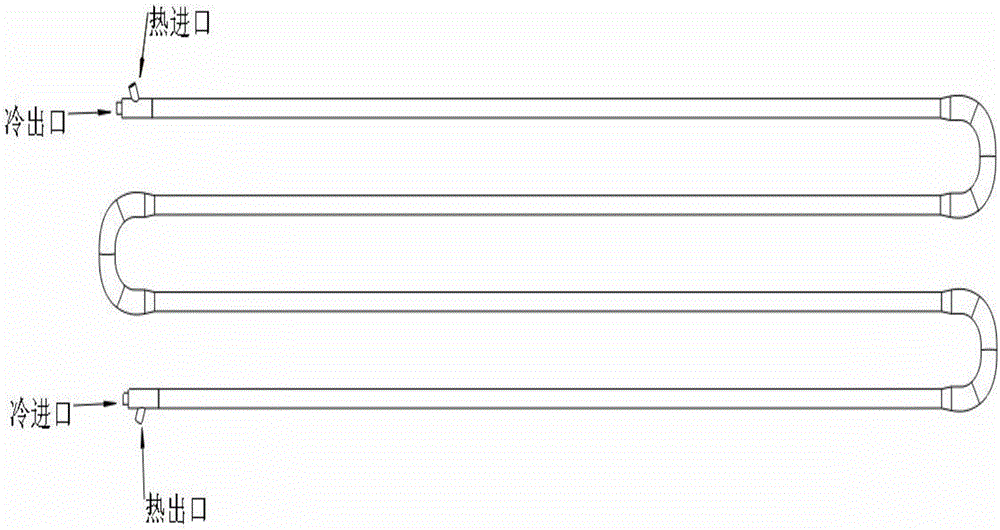

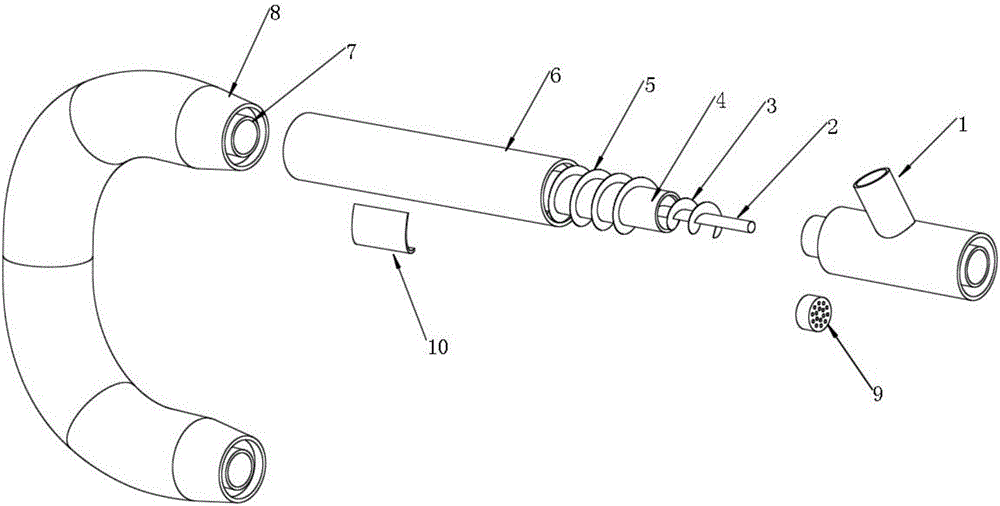

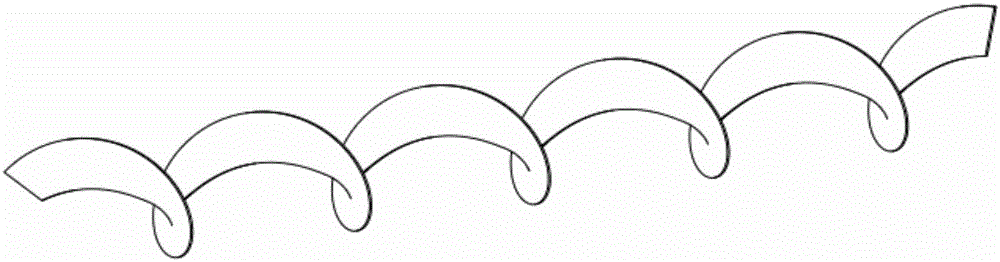

[0023] Depend on Figure 1 to Figure 9 As shown, this kind of internal and external double spiral flow centrifugal heat exchanger includes a pair of inlet and outlet joints 1 and several straight pipe sections and several elbow pipe sections connected in sequence between the pair of inlet and outlet joints. The outlet joint, several straight pipe sections and several bent pipe sections are all formed by nesting the outer pipe 6 and the inner pipe 4. Its unique feature is that there is an inner branch pipe 2 in the inner pipe 4 of the straight pipe section, which surrounds the inner pipe The branch pipe is fixed with a group of internal helical pieces 3, and the outer edge of the internal helical piece is in contact with the inner wall of the inner pipe 4 of the straight pipe section; a group of outer helical pieces 5 are fixed around the outer wall of the inner pipe 4 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com