ADCA (Azodicarbonamide) foaming agent liquid waste disposal process

A technology of waste liquid treatment and foaming agent, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, inorganic chemistry, etc., to achieve obvious effects, reduce short-circuit temperature difference loss, and reduce fluid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] For further elaborating the technical means and effects that the present invention takes to achieve the intended invention purpose, below in conjunction with accompanying drawing and preferred embodiment, its specific implementation method of ADCA foaming agent waste liquid treatment process that proposes according to the present invention is described in detail as follows: Rear.

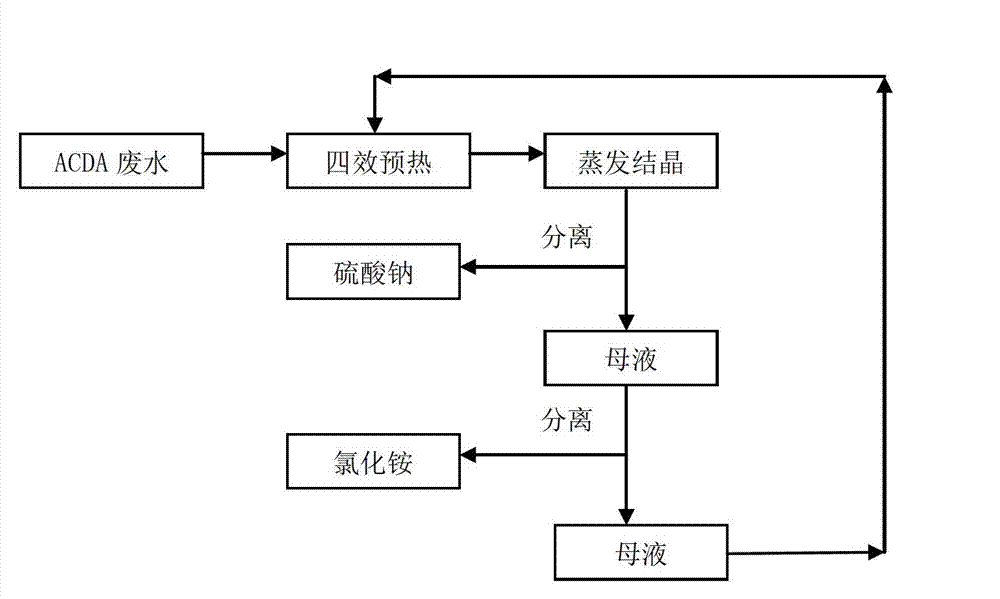

[0074] see figure 1 Shown, the ADCA foaming agent waste liquid treatment process of preferred embodiment of the present invention, it mainly comprises the following steps:

[0075] (1) Preheat. The waste liquid is preheated to 40°C-60°C in four stages with the next-stage material (or called four-effect or four-stage preheating). Among them, the advantage of step-by-step heating is energy saving. Preheating the material with the material can preheat the original material with the next level of material; if heating from the original temperature to the required temperature at one time, the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com