Bionic array structure surface antifouling drag reduction material

An array structure and antifouling technology, applied in antifouling/underwater coatings, biocide-containing paints, coatings, etc., can solve the problems of complex manufacturing and single structure, reduce fluid resistance, easily obtain raw materials, reduce The effect of small running resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

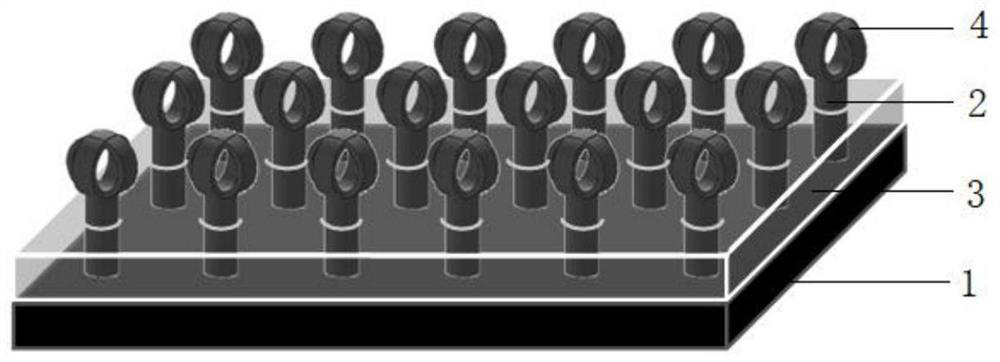

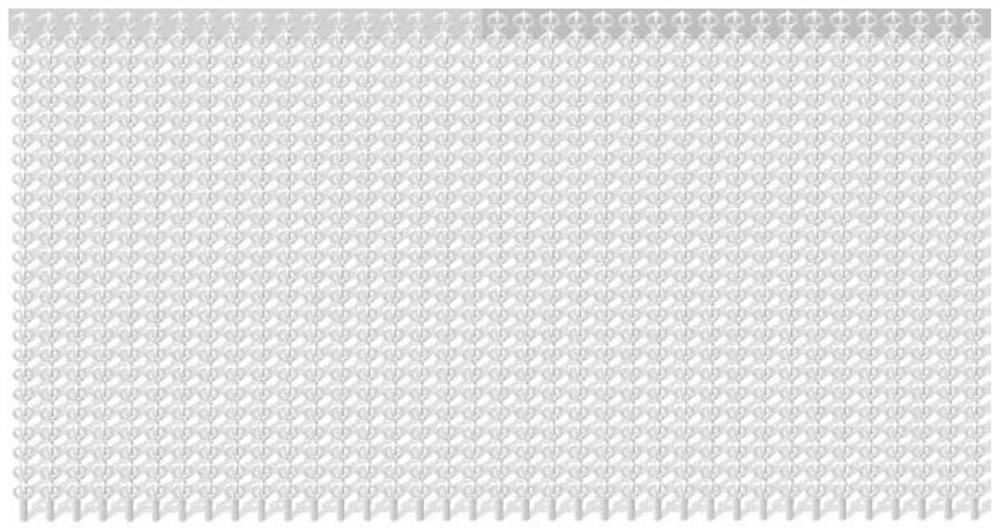

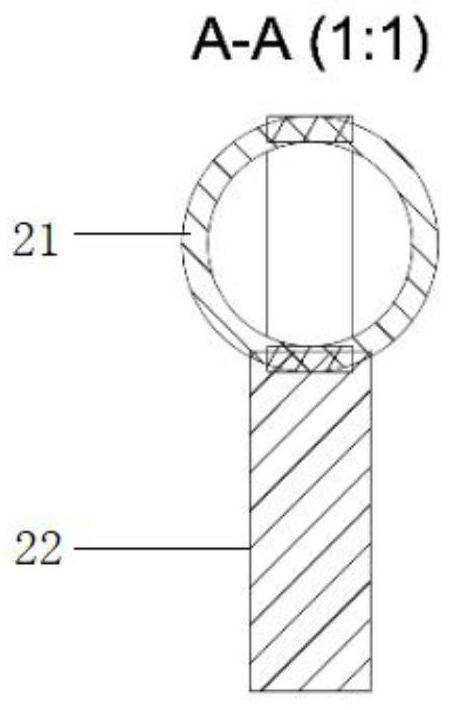

[0024] The main structure of the anti-fouling and drag-reducing material on the surface of the bionic array structure involved in this embodiment includes a base layer 1, a surface structure layer 2, a hydrophobic layer 3 and a modified layer 4; the base layer 1 is provided with a surface layer structure layer 2, and the base layer 1 and the surface structure layer 2 is provided with a hydrophobic layer 3, and the top of the surface structure layer 2 is covered with a modified layer 4; the surface structure layer 2 is composed of several anti-fouling and drag-reducing units 20 arranged in a matrix, two adjacent The horizontal spacing and vertical spacing of the antifouling and drag reducing units 20 are both 2000 μm; each antifouling and drag reducing unit 20 is composed of a head ring 21 and a pillar 22. The head ring 21 is fixedly connected to the top of the pillar 22, and the pillar The bottom end of 22 is fixedly connected with the base layer 1; the head ring 21 is a cross ...

Embodiment 2

[0027] Both the base layer 1 and the surface structure layer 2 involved in this embodiment are made of polymer materials, including but not limited to ABS resin, epoxy resin, acrylic resin, PLA resin and LCD resin.

[0028] The preparation process of the anti-fouling and drag-reducing material on the surface of the bionic array structure involved in the present invention includes three steps of preparing the base layer 1 and the surface structure layer 2, preparing the modified layer 4 and preparing the hydrophobic layer 3:

[0029] (1) Preparation of base layer 1 and surface structure layer 2: ABS resin is prepared into base layer 1 and surface structure layer 2 by 3D printing, wherein the size of base layer 1 is 150mm×75mm;

[0030] (2) Preparation of modified layer 4: hang the head ring 21 upside down and then nano-SiO 2 In the mixed sample of particles and silane coupling agent KH560, the surface of the head ring 21 is hydrophobically modified;

[0031] (3) Prepare the hy...

Embodiment 3

[0033] This example involves the test of the inhibition rate of the antifouling and drag reducing material on the surface of the bionic array structure to the attachment of mussel silk: the antifouling and drag reducing material on the surface of the bionic array structure prepared in Example 2 and the blank ABS resin material were put into seawater at the same time, Put 10 mussels on the surface of the two groups of materials respectively, observe the number of secretion and attachment of the mussel foot silk on the surface of the two groups of materials after 24 hours, and compare with the inhibition rate of the blank ABS resin material on the attachment of the mussel foot silk to calculate: bionic array The anti-fouling and drag-reducing material on the surface of the structure can inhibit the attachment of mussel silk by 92%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com