Stop valve of pipeline

A technology for stop valves and pipelines, which is applied in the direction of lifting valves, valve devices, engine components, etc., can solve the problems of inability to reduce the local flow resistance of the valve chamber, vortex generation, and complicated medium flow, so as to save pipeline operating costs and reduce fluid flow. Effect of drag, local drag drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

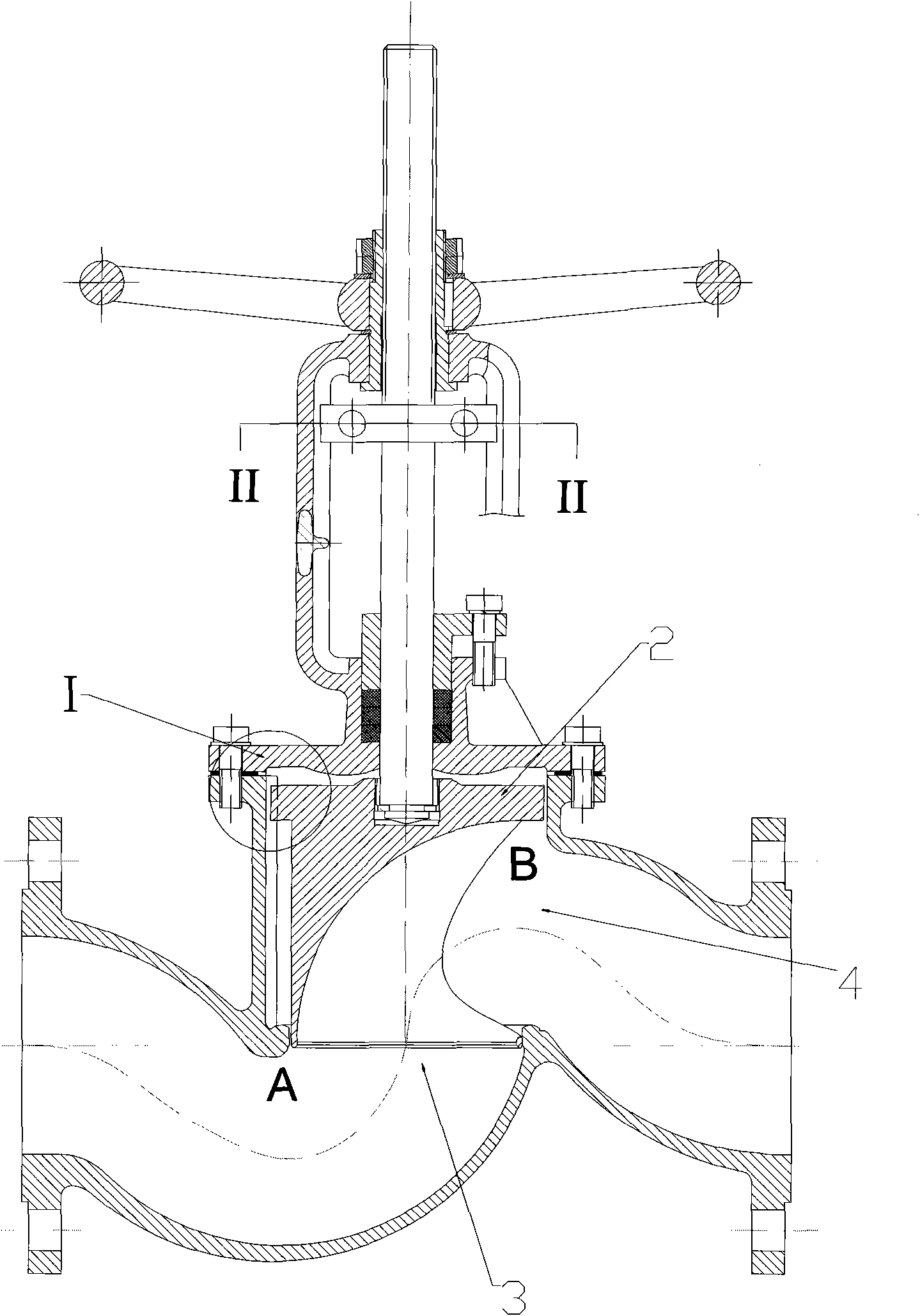

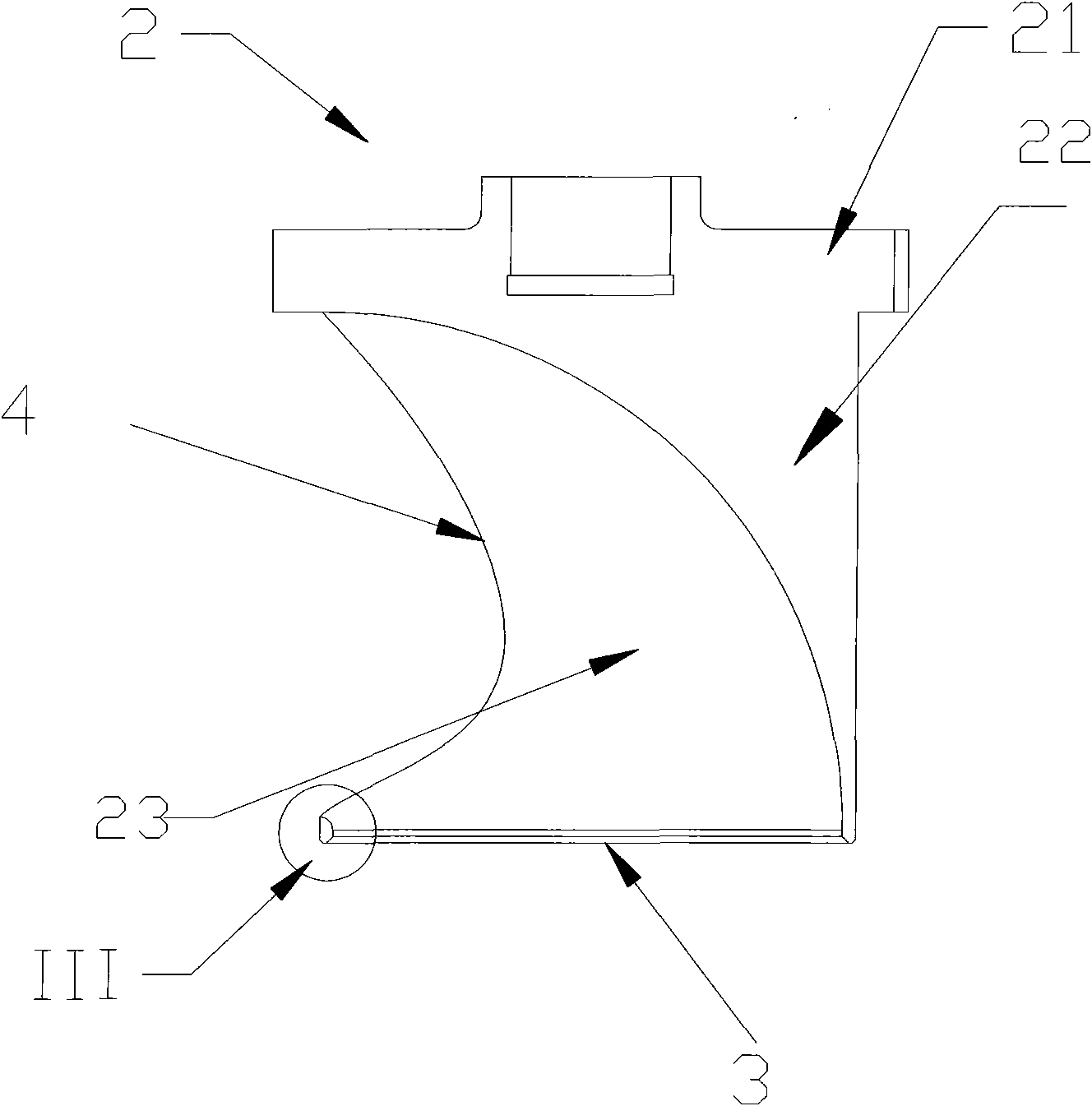

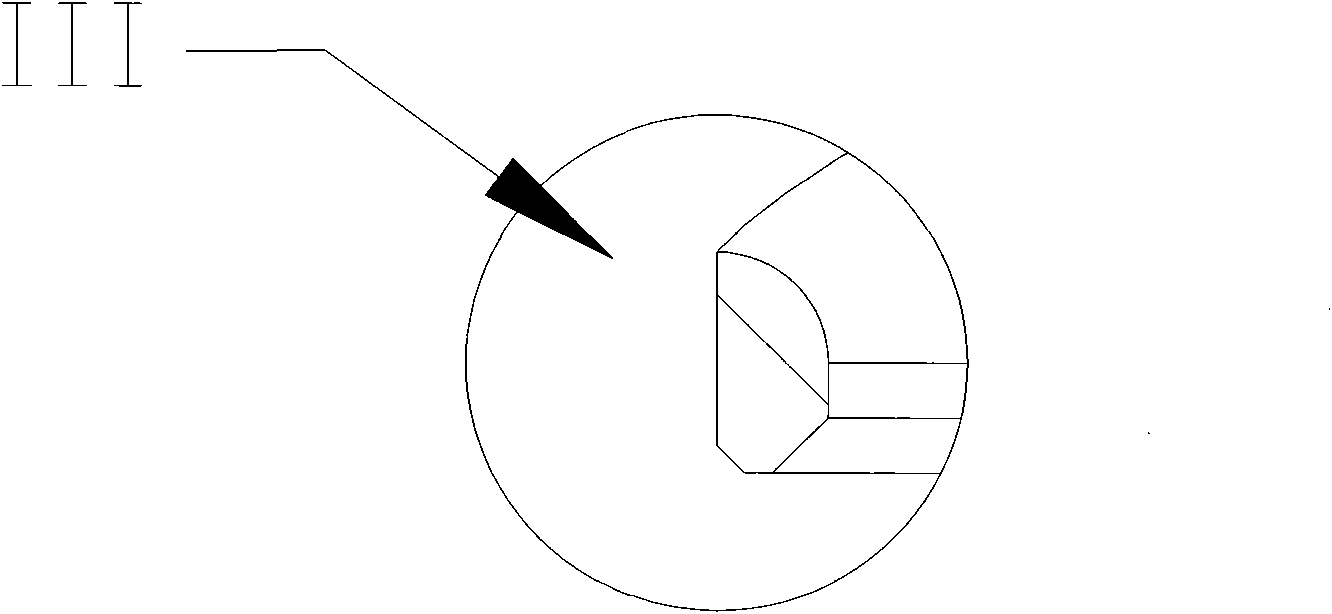

[0017] Such as figure 1 , figure 2 As shown, the present invention includes a valve body 1 and a valve disc 2, the fluid inlet 3 and the fluid outlet 4 of the valve body 1 turn smoothly at 90 degrees, and the outer surface of the valve disc 2 is formed by an integral flat-shaped sealing disc 21 and a lower cylinder 22 perpendicular to the sealing valve plate 21, the inner surface of the lower cylinder 22 of the valve disc is a cylindrical ring surface 23, and the cylindrical ring surface 23 is at the fluid inlet 3 and the sealing surface of the valve seat 5 is vertical, and the outlet 4 is tangent to the valve body inlet 6, that is, the tangent to the centerline of the cylinder annulus at the outlet 4 coincides with the tangent to the centerline of the cross-section at the valve body inlet. Said cylindrical ring surface 23 can be a cylindrical ring with equal diameter, or a cylindrical ring with variable diameter.

[0018] When the valve is fully open, the outer cylindrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com