Erecting method of underground roadway filling pipeline

A pipeline hanger and pipeline technology, which is applied in the direction of filling, mining equipment, earthwork drilling, etc., can solve the problems of easy sedimentation of slurry, increase of local resistance, and increase of roadway section, so as to reduce labor intensity of workers and local Resistance, avoiding the effect of bumps and ups and downs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

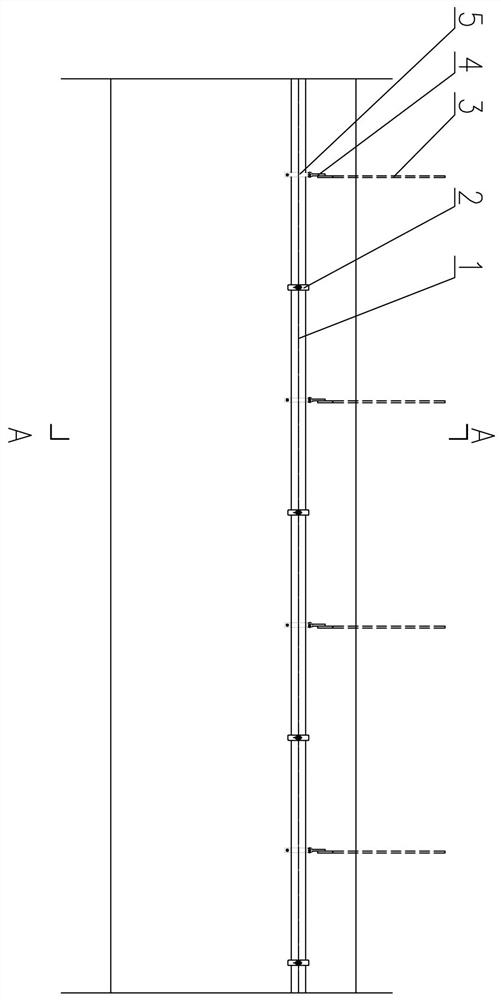

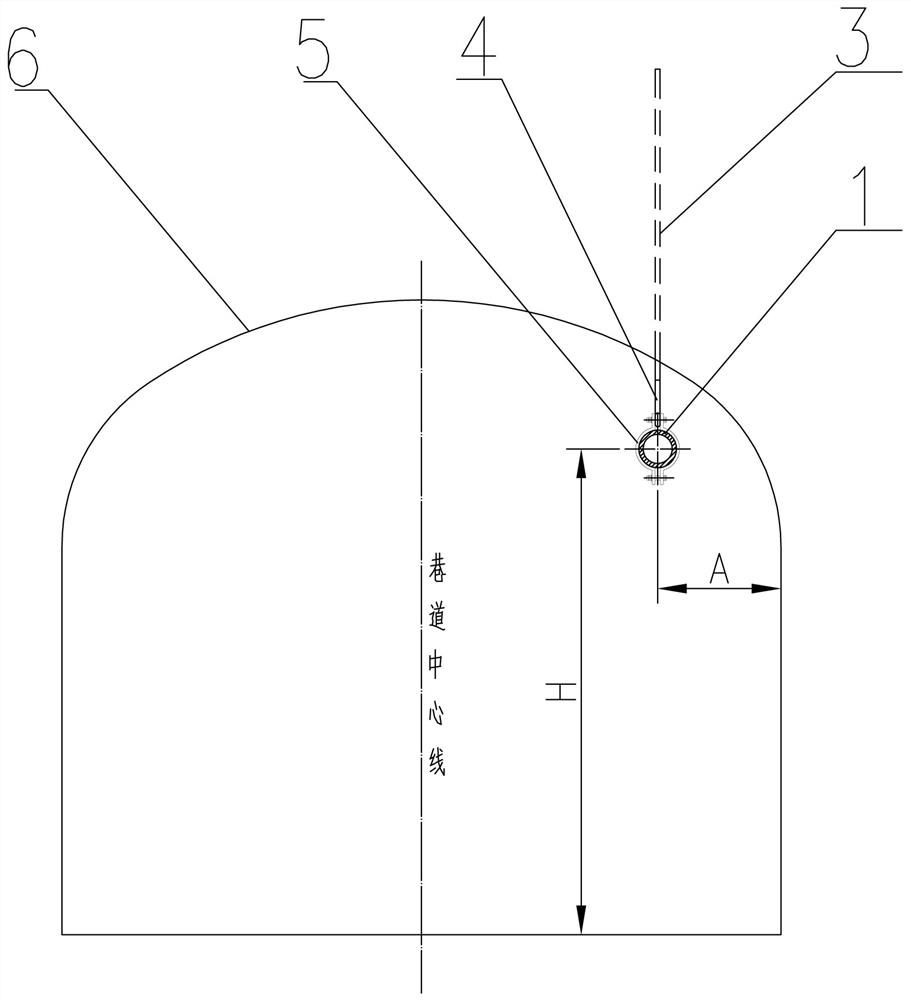

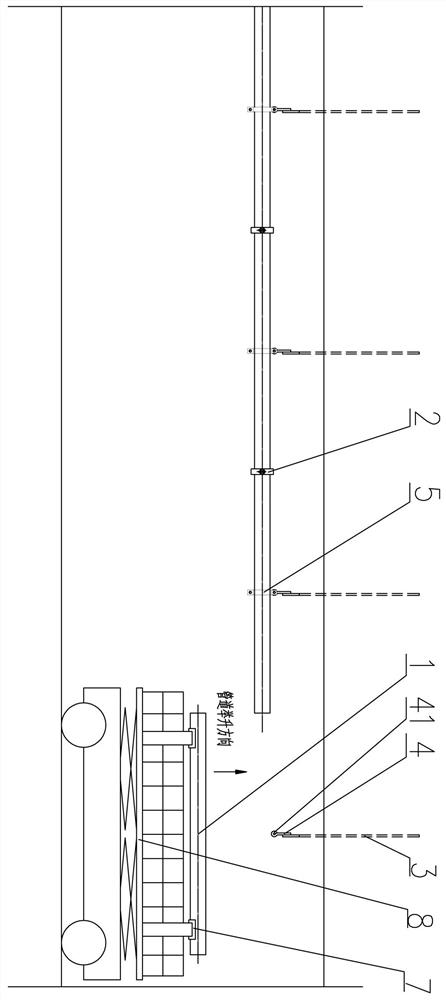

[0029] Such as Figure 1-Figure 7 As shown, the erection method of a kind of downhole filling pipeline of the present invention is characterized in that: comprises the following steps:

[0030] Step 1: Determine the height of the filling pipeline from the floor of the roadway 6 according to the safe passage height of vehicles and equipment,

[0031] The determination of the safe passage height of its vehicles and equipment refers to the safe passage height of the equipment. The gap between the protruding parts is ≥300mm.

[0032] Step 2: Arrange the anchor rods 3 in a row at equal intervals along the flow direction of the slurry in the filling pipeline 1 on the vault of the tunnel 6; The bottom of the bottom is welded with a tail ring 41, and the upper end of the anchor rod 3 is fixed on the vault of the roadway 6 through a cement mortar anchor;

[0033] Step 3: Layout of the filling pipeline

[0034] The filling pipeline 1 is composed of multiple pipe sections, and each s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com