Aluminium electrolysis cell anode carbon block

An anode carbon block and aluminum electrolytic cell technology, which is applied in the field of aluminum electrolysis, can solve the problems of uneven discharge of anode gas, destruction of the original anode, high current density, etc., so as to avoid falling off of small single anodes, reduce discharge resistance and local resistance. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

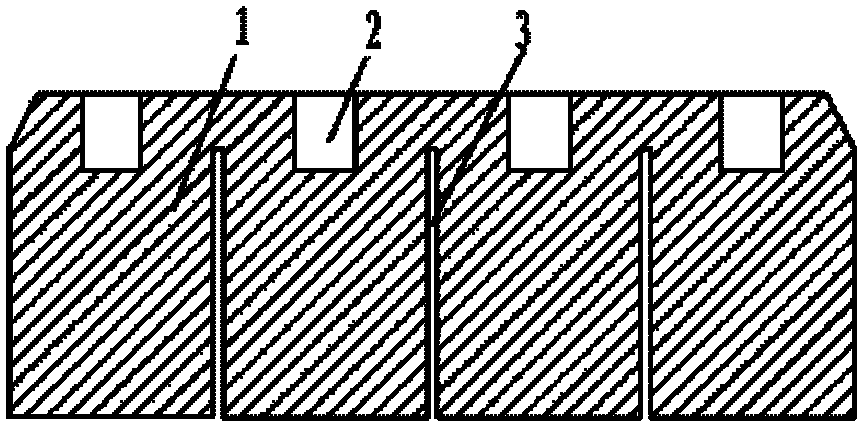

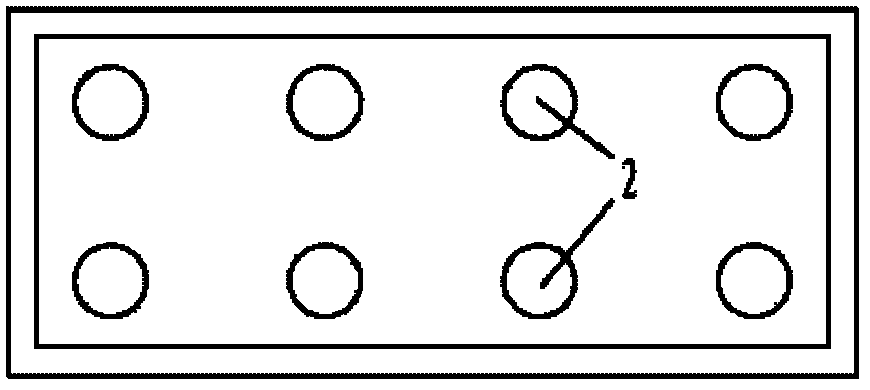

[0036] Such as figure 1 , figure 2 , image 3 As shown, in this embodiment 1, the upper surface of the anode carbon block is provided with 2 rows of carbon bowls, each row has 4, 2 rows of 8 carbon bowls in total, the depth of the carbon bowls is 100-200mm, and the inner diameter is 100 mm. ~200mm, the width of the anode substrate is 600~800mm, and the length is 1500~2000mm. In the longitudinal direction of the anode, there are three slots perpendicular to the longitudinal direction of the anode between the upper surface of the carbon block 50-200mm below the upper surface of the carbon block in the middle of the two adjacent carbon bowls in the front and back rows to the bottom palm of the anode. The width of the groove is 10-30mm, and the length of the groove is the same as the width of the anode.

[0037] There is also a slot with a width of 10-30mm between the upper surface of the anode carbon block and the bottom palm of the anode between the upper surface of the anod...

Embodiment 2

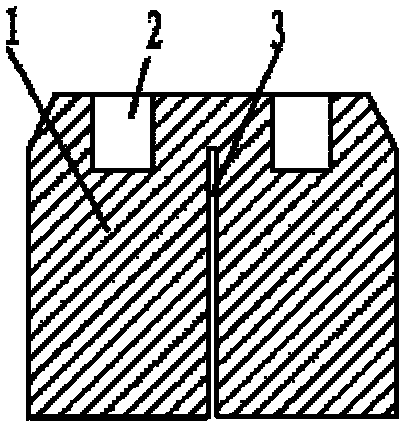

[0039] Such as Figure 4 , Figure 5 , Image 6 shown. In this embodiment 2, the upper surface of the anode carbon block is provided with 2 rows of carbon bowls, each row has 4, 2 rows of 8 carbon bowls in total, the depth of the carbon bowls is 100-200mm, and the inner diameter is 100-200mm. The width of the anode substrate is 600-800mm, and the length is 1500-2000mm. In the longitudinal direction of the anode, there are three slots perpendicular to the longitudinal direction of the anode between the upper surface of the carbon block 50-200mm below the upper surface of the carbon block in the middle of the two adjacent carbon bowls in the front and back rows to the bottom palm of the anode. The width of the groove is 10-30mm, and the length of the groove is the same as the width of the anode substrate.

[0040] Example 2 differs from example 1 in that there are no grooves in the longitudinal direction of the carbon anode.

Embodiment 3

[0042] Such as Figure 7 , Figure 8 , Figure 9shown. In this embodiment 3, the upper surface of its anode carbon block is provided with 2 rows of carbon bowls, each row has 4, 2 rows of 8 carbon bowls in total, the depth of the carbon bowls is 100-200mm, and the inner diameter is 100-200mm. The width of the anode substrate is 600-800mm, and the length is 1500-2000mm. In the longitudinal direction of the anode, there are three slots perpendicular to the longitudinal direction of the anode between the upper surface of the carbon block 50-200mm below the upper surface of the carbon block in the middle of the two adjacent carbon bowls in the front and back rows to the bottom palm of the anode. The width of the groove is 10-30mm, and the length of the groove is the same as the width of the anode substrate.

[0043] In the transverse direction of the anode carbon block, there is a slot in the longitudinal direction between the upper surface of the carbon block 50-200mm below t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com