Continuous Atmosphere Protection Production Line for High Temperature Lithium Iron Phosphate Calcination

A high-temperature calcination and lithium iron phosphate technology, which is applied in the direction of phosphorus compounds, furnace types, lighting and heating equipment, etc., can solve the problem that product output, quality and production cost cannot be taken into account at the same time, affect equipment life and material uniformity, and cannot guarantee materials Synchronization and other issues, to achieve the effect of shortening the cooling time and design, reducing the passing cross-sectional area, and enhancing the effect of radiation heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

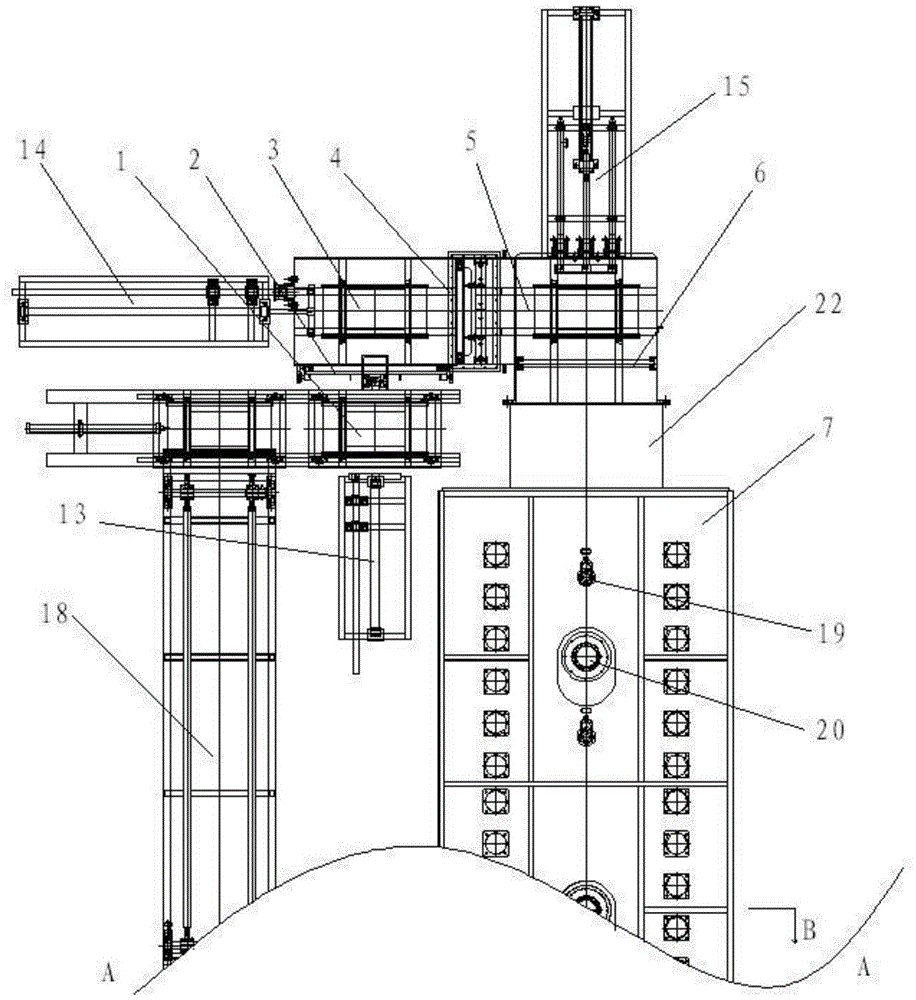

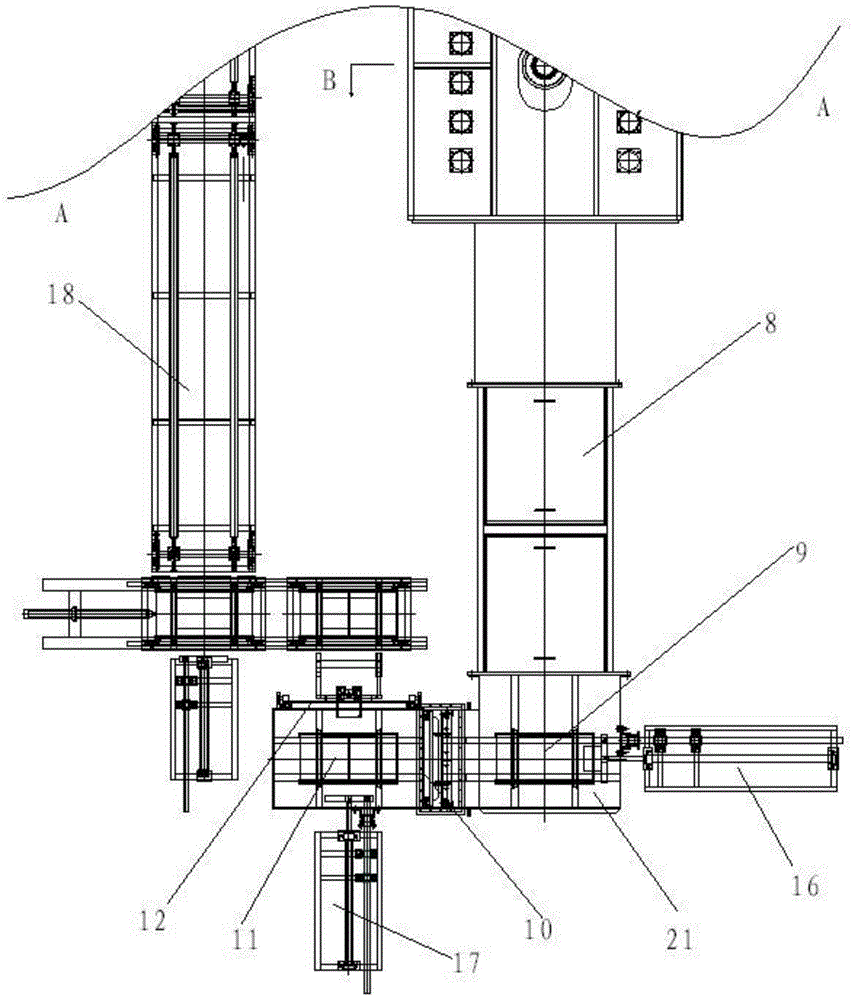

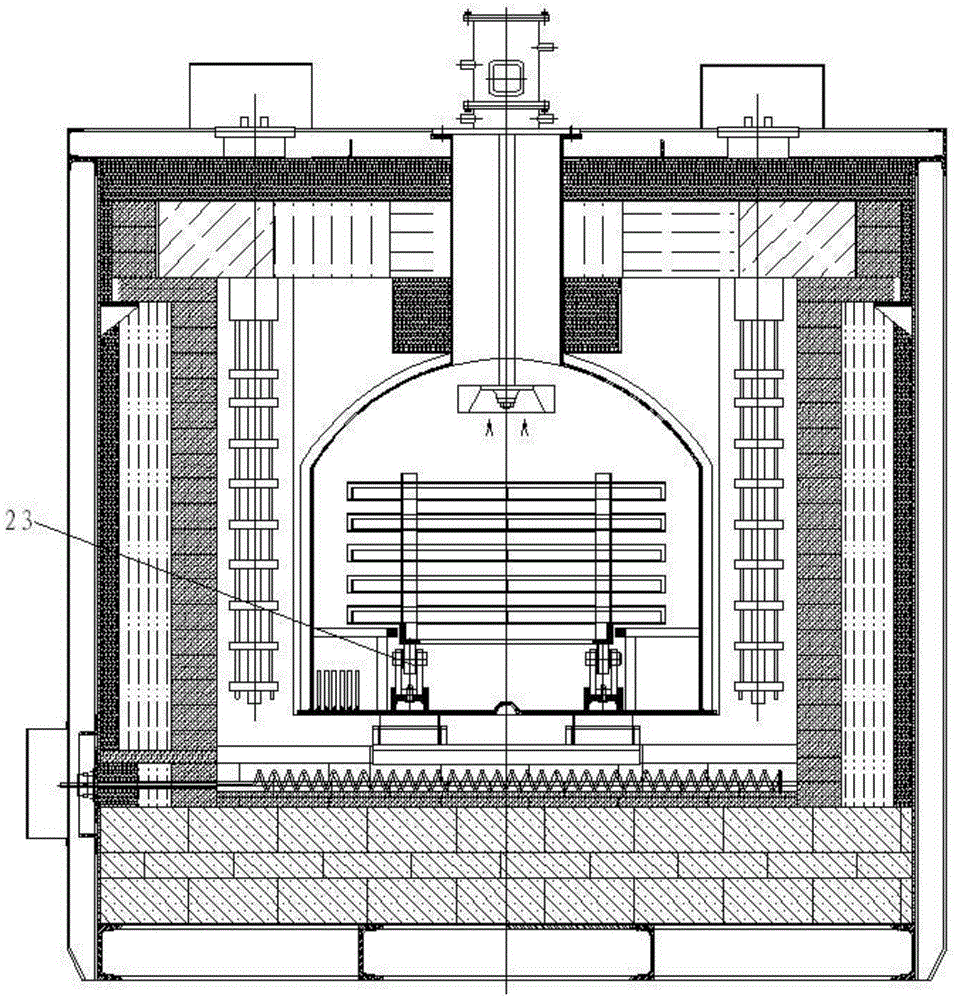

[0048] figure 1 and figure 2 It is a structural schematic diagram of the production line of this embodiment; figure 1 and 2 As shown, the continuous high-temperature calcination atmosphere protection production line for lithium iron phosphate includes a feed conveyor belt, a discharge conveyor belt, a feed airlock cabin, a heating furnace, a discharge airlock cabin, and a loading and unloading conveyor belt. The heating furnace in this embodiment adopts the muffle heating furnace in the prior art.

[0049] The feed airlock chamber is arranged at the feed port of the heating furnace, and the discharge airlock chamber is arranged at the discharge port of the heating furnace. The two ends of the loading and unloading conveyor belt 18 are respectively connected with the feed conveyor belt and the discharge conveyor belt.

[0050] The feed conveyor belt is connected to the feed airlock cabin, a feed waiting position 1 is set on the feed conveyor belt, and a feed cylinder 13 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com