Coiled tubing tractor and working method thereof

A tractor and tubing technology, which is applied to coiled tubing tractors and their working fields, can solve the problems of tractor distortion and insufficient power, and achieve the effect of large traction force and increased traction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

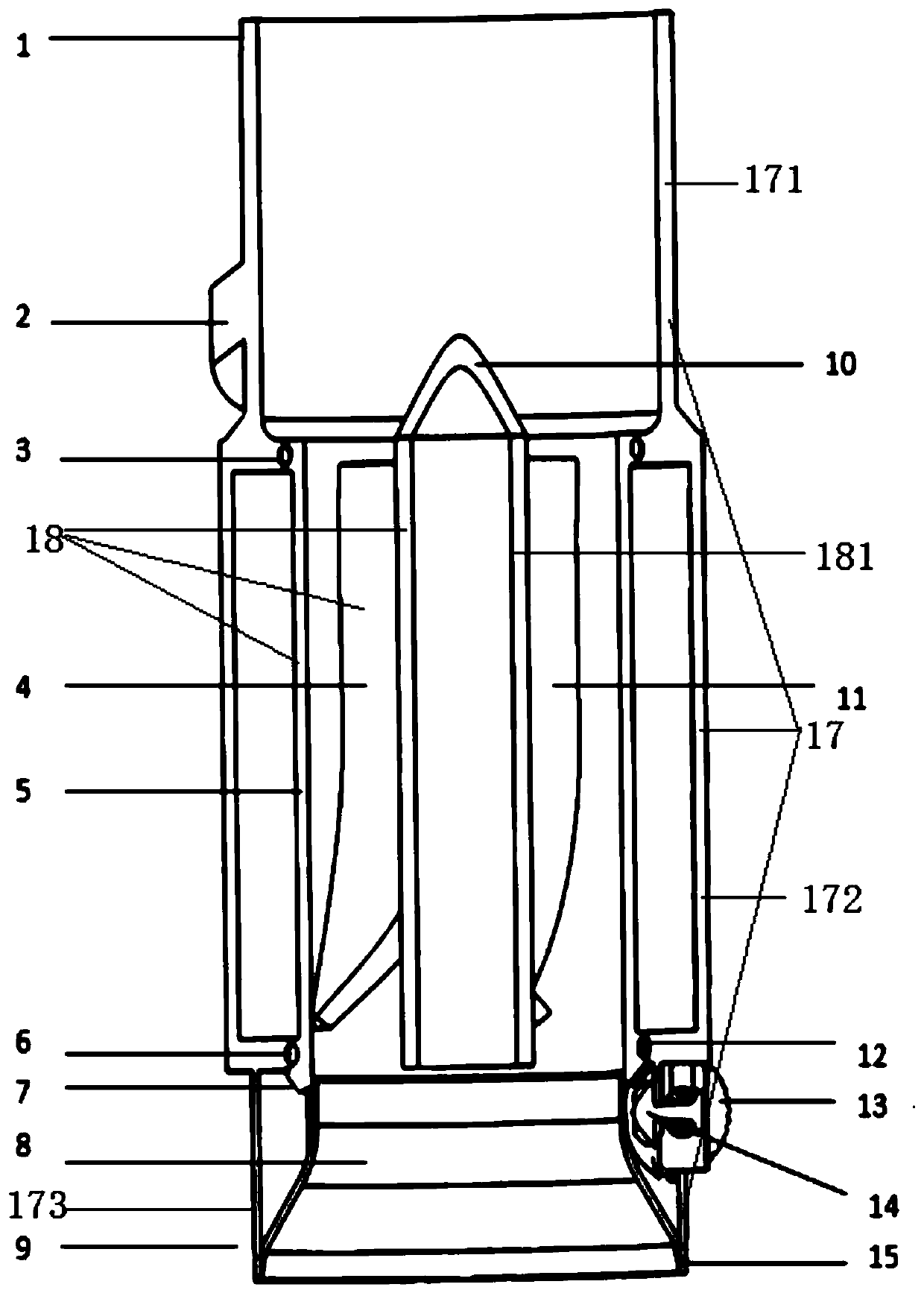

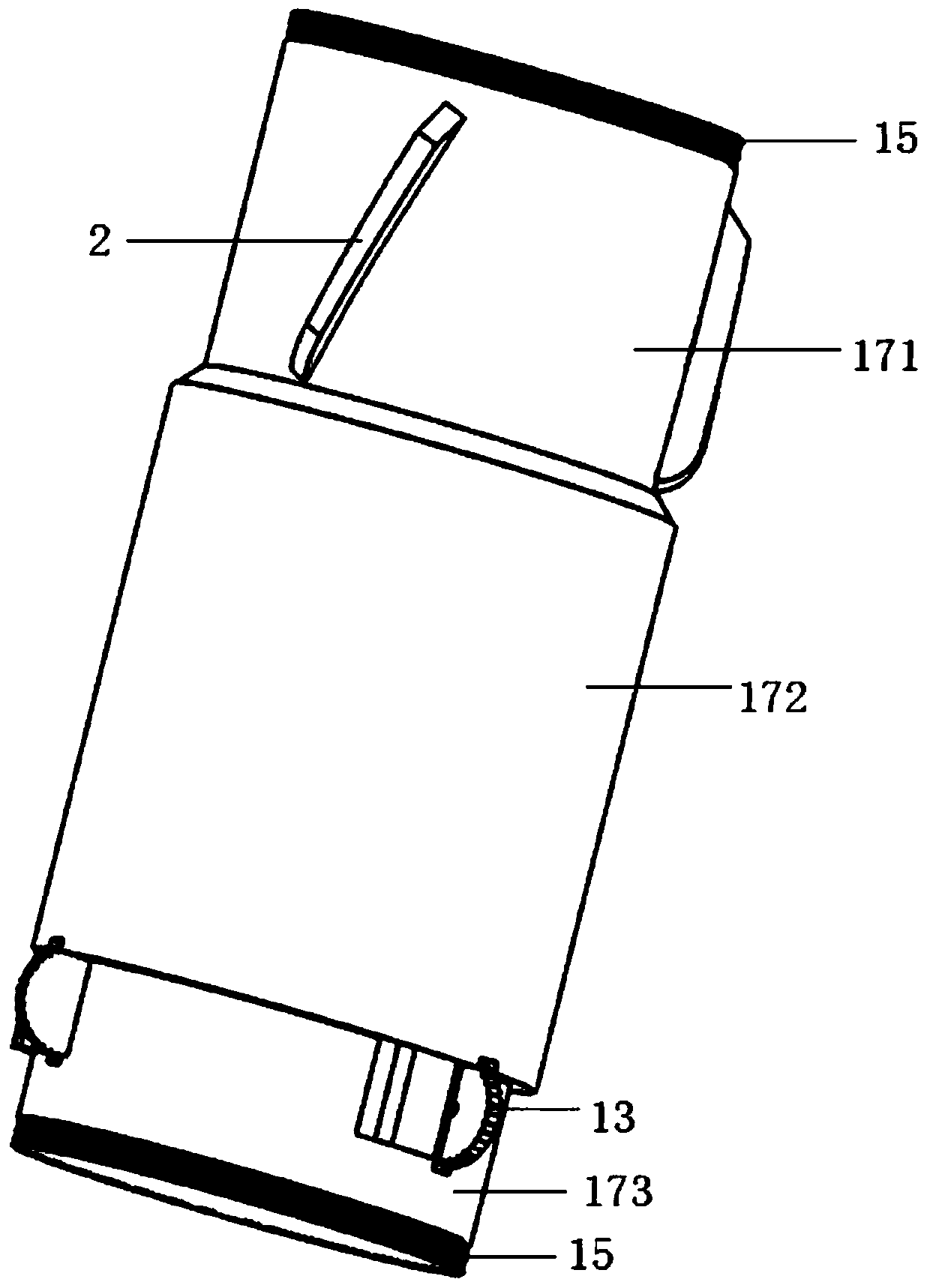

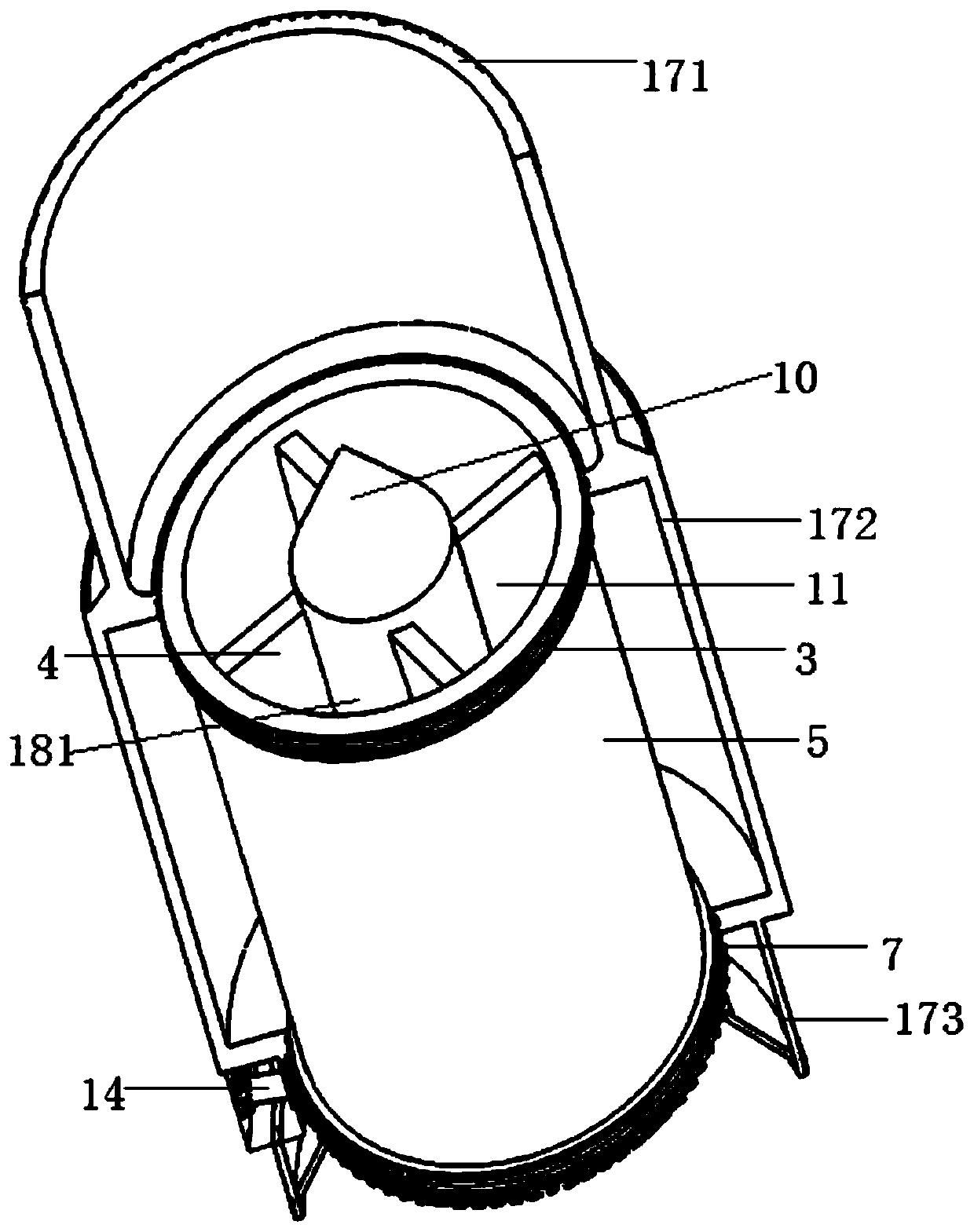

[0085] like Figure 1-Figure 6 As shown, a coiled tubing tractor is connected between the downhole power drilling tool and the coiled tubing, and includes a casing 17, a rotor 18 and a steering system, the casing 17 acts as a stator, and the rotor 18 and the steering system are arranged in the casing 17, The rotor 18 can rotate at high speed under the impact of the high-pressure drilling fluid to generate power; the steering system includes the main steering shaft 14, the auxiliary steering shaft 16 and the creeping wheel 13. The steering system is used to change the output direction of the power so that it drives the coiled tubing Advance in horizontal wells. The power generated by the drilling fluid is transmitted to the auxiliary steering shaft 16 and the crawling wheel 13 through the main steering shaft 14 to generate traction.

[0086] The rotor 18 includes a shaft 181 , and a plurality of blades are provided on the outer side of the shaft 181 . The blades at least incl...

Embodiment 2

[0098] A working method of a coiled tubing tractor, comprising the following steps:

[0099] (1) First install the coiled tubing tractor between the downhole motor and the coiled tubing;

[0100] (2) Turn on the surface mud pump, and the drilling fluid flows into the inside of the coiled tubing and enters the rotor inside the casing;

[0101] (3) Drilling fluid continuously impacts the rotor to make it rotate continuously, thereby driving the main steering shaft 14 to rotate;

[0102] (4) The main steering shaft 14 drives the auxiliary steering shaft 16 to rotate through the steering rack 7, and provides steering force for the climbing wheel 13, thereby enabling it to climb.

[0103] like Figure 1-Figure 4 As shown, the rotor 18 includes a shaft 181, and a plurality of blades are arranged on the outer side of the shaft 181 . The blades at least include blade II4 and blade II11. A guide cone 10 is provided on the upper part of the shaft 181, and the upper end of the guide c...

Embodiment 3

[0114] A coiled tubing tractor, the difference from Embodiment 1 is that the casing 17 is a hollow cylindrical structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com