Core drill suitable for hard fractured formation

A technology for coring drills and coring bits, which is applied in the fields of extraction of undisturbed cores, earthwork drilling, etc., can solve the problems of lack of formation information, increase of drilling operation costs, slow progress of engineering operations, etc., so as to improve coring efficiency and improve efficiency. success rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

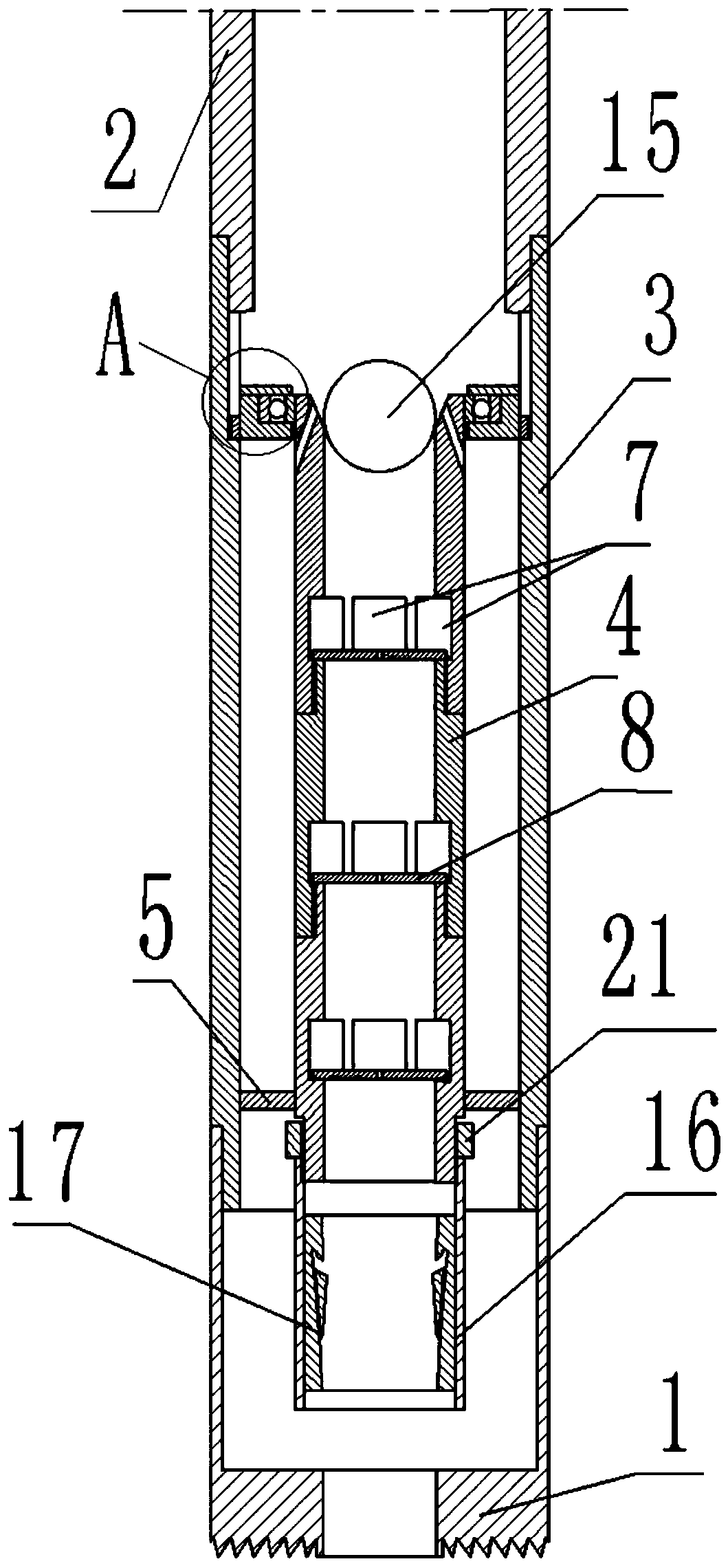

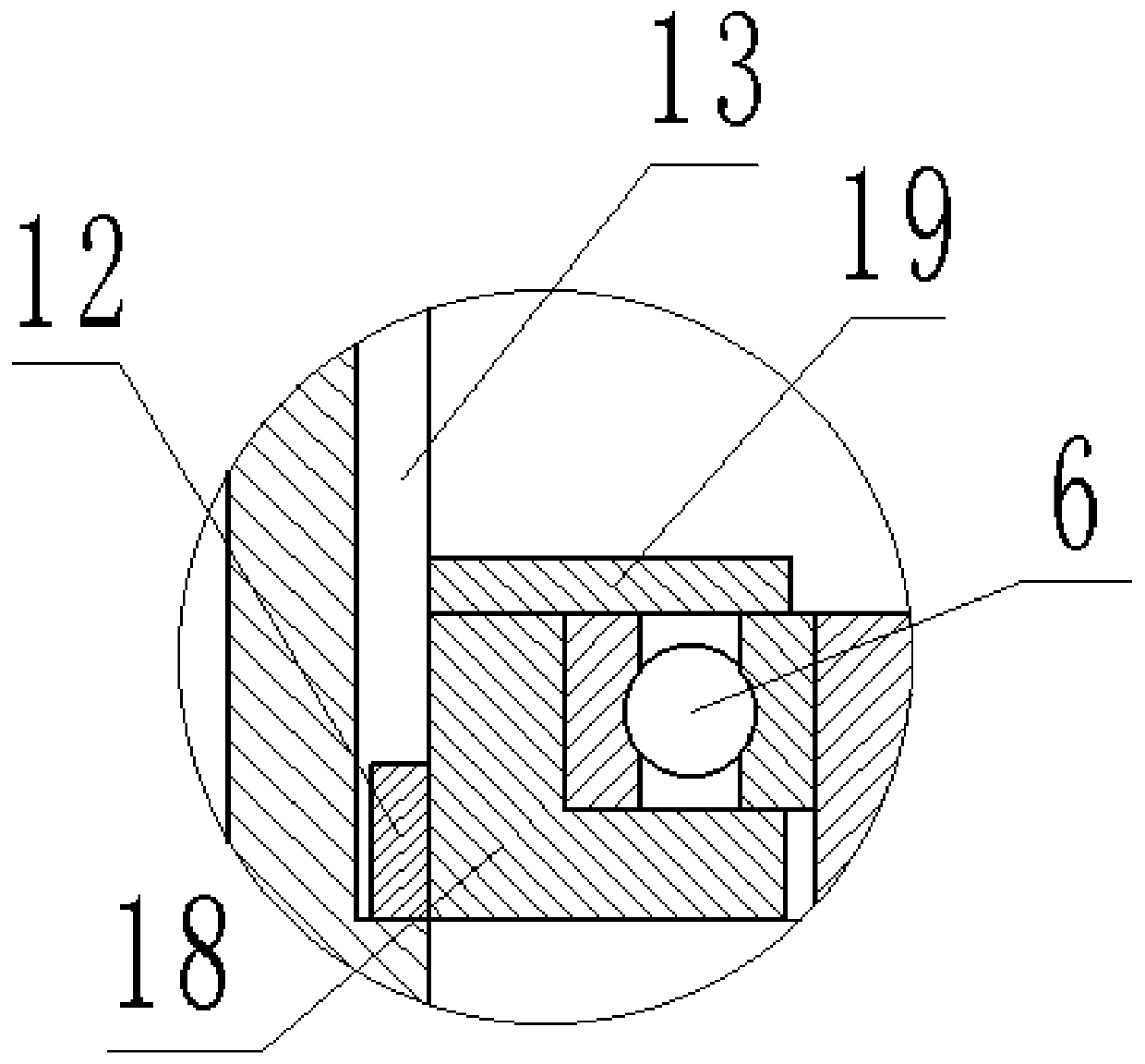

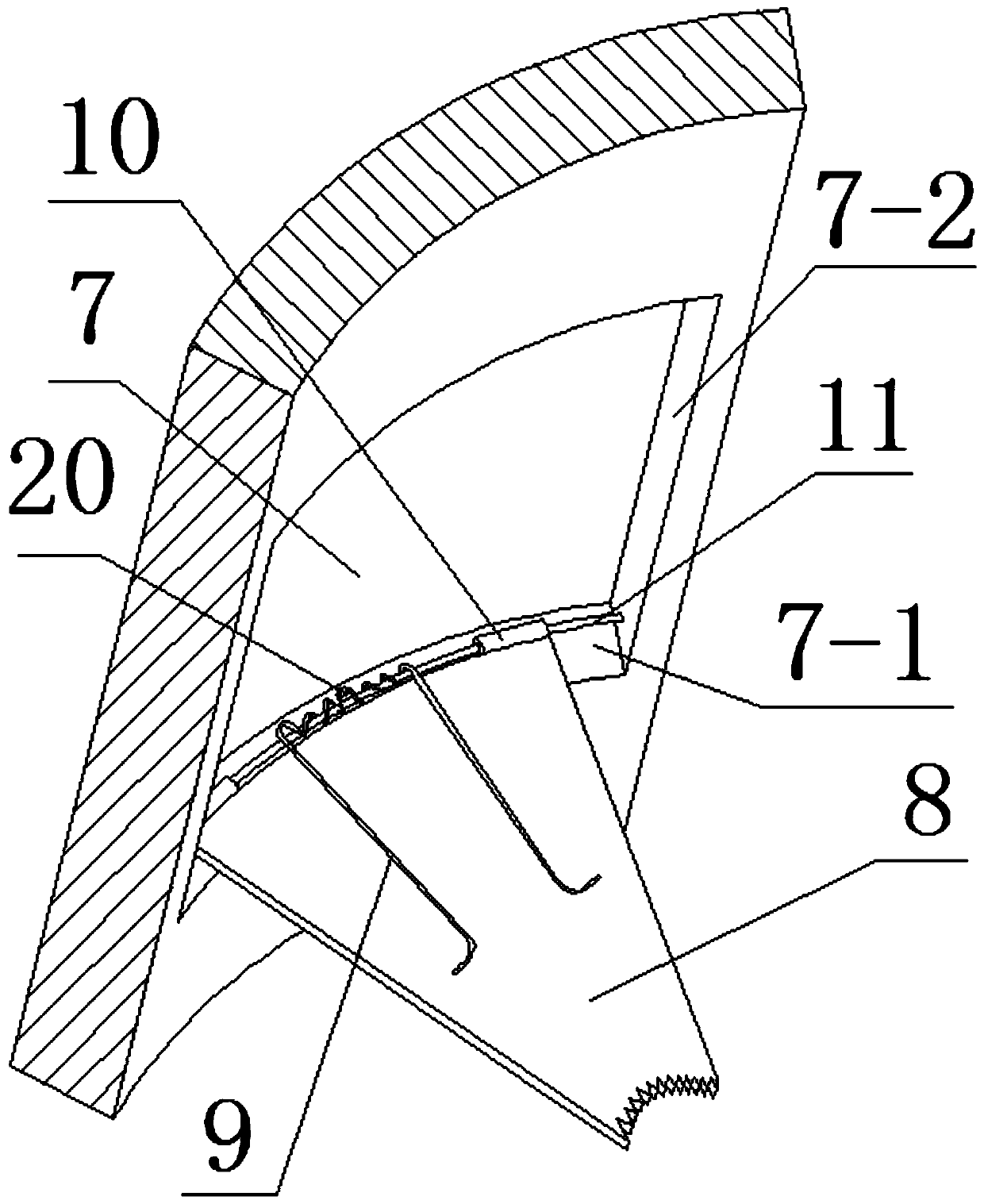

[0020] see figure 1 , 2 , 3, 4 and Figure 5 , the present invention includes a core bit 1, a drill pipe 2, an outer pipe 3, an inner pipe, a centralizing block 5 and a supporting part; the upper part of the outer pipe 3 is connected to the drill pipe 2, and the lower part is connected to the core bit 1; the outer pipe 3 A centralizing block 5 is provided on the inner wall of the lower side; a supporting part is provided between the inner pipe and the outer pipe 3; it is characterized in that: the inner pipe is composed of a plurality of tubes 4, and the tubes 4 are connected by threads. Dividing the inner tube into multiple tubes 4 can make the processing technology easier to realize, and can also facilitate workers to overhaul the inner tube; the inner wall of the tube 4 is provided with a plurality of axially symmetrical grooves 7, and on the grooves 7 A lock core mechanism is provided; the lock core mechanism includes a rebound member and a lock core plate 8; the lock co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com