A drilling tool centralizer

A technology for centralizers and drilling tools, which is applied in the direction of drill pipe, drill pipe, earthwork drilling, etc. It can solve the problems of fast wear of wear-resistant band, long repair period, and high drilling cost, so as to reduce the contact area and trim the size of the well wall , to avoid the effect of drill sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereby.

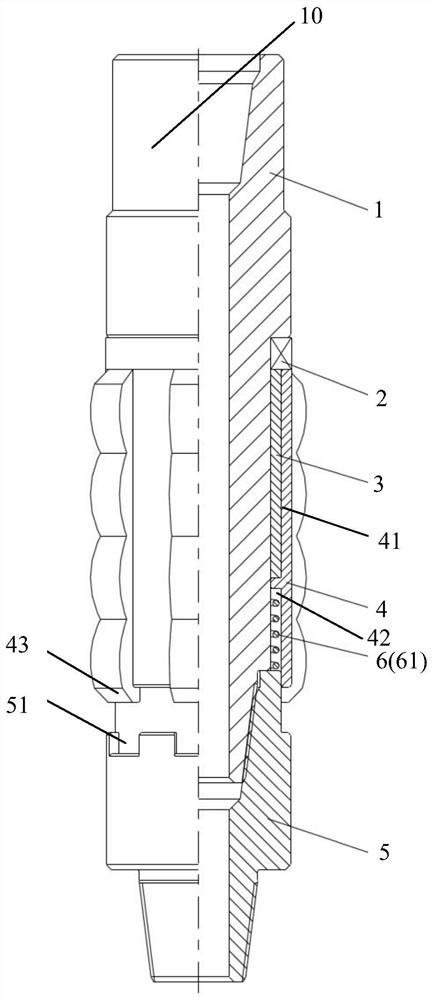

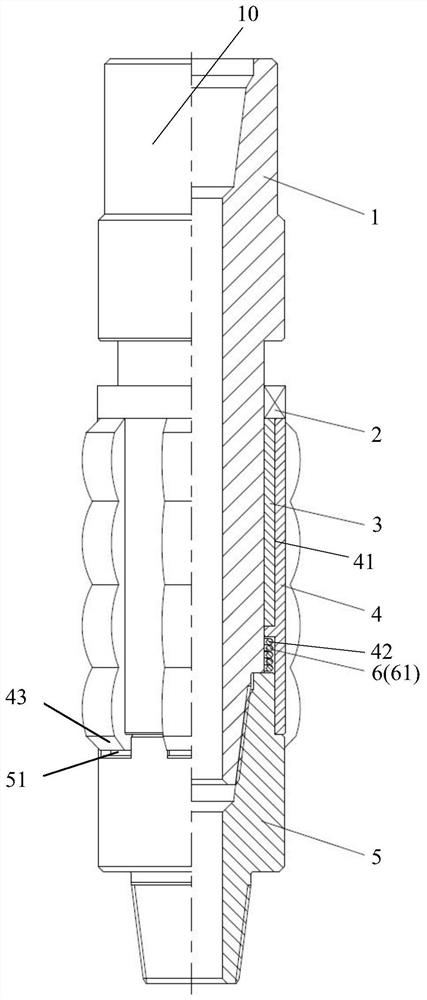

[0023] figure 1 It schematically shows the working state of the drilling tool centralizer 10 in the embodiment of the present invention when drilling. figure 2 It schematically shows the working state of the drilling tool centralizer 10 in the embodiment of the present invention when lifting the drilling tool after being blocked.

[0024] Such as figure 1 with figure 2 As shown, the drilling tool centralizer 10 of the embodiment of the present invention includes a mandrel 1 , a bearing 2 , a bearing bush 3 , a support sleeve 4 and a lower joint 5 . The top of the mandrel 1 is connected with the upper drilling tool, the bottom of the mandrel 1 is connected with the top of the lower joint 5, and the bottom of the lower joint 5 is connected with the lower dril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com