All-metal dynamic seal concentric righting type underground volume motor

A dynamic sealing and all-metal technology, applied in the field of motors, can solve problems such as low temperature resistance, affecting the performance and life of screw motors, and failing to meet the needs of deep wells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

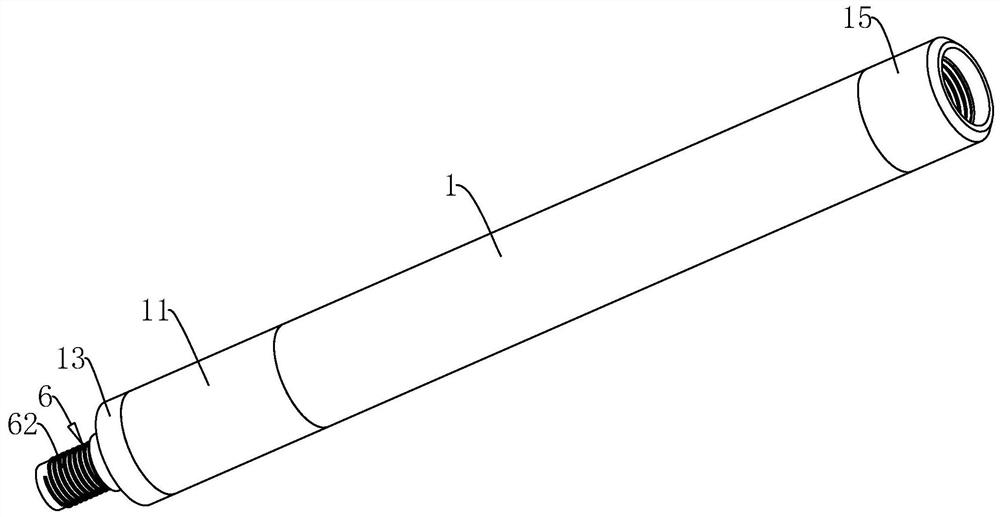

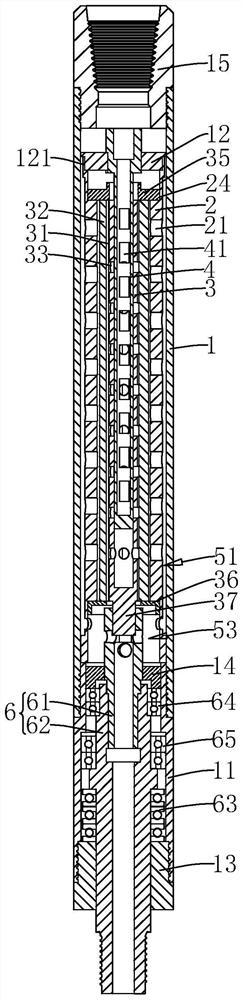

[0040] Attached to the following Figure 1-6 This application will be described in further detail.

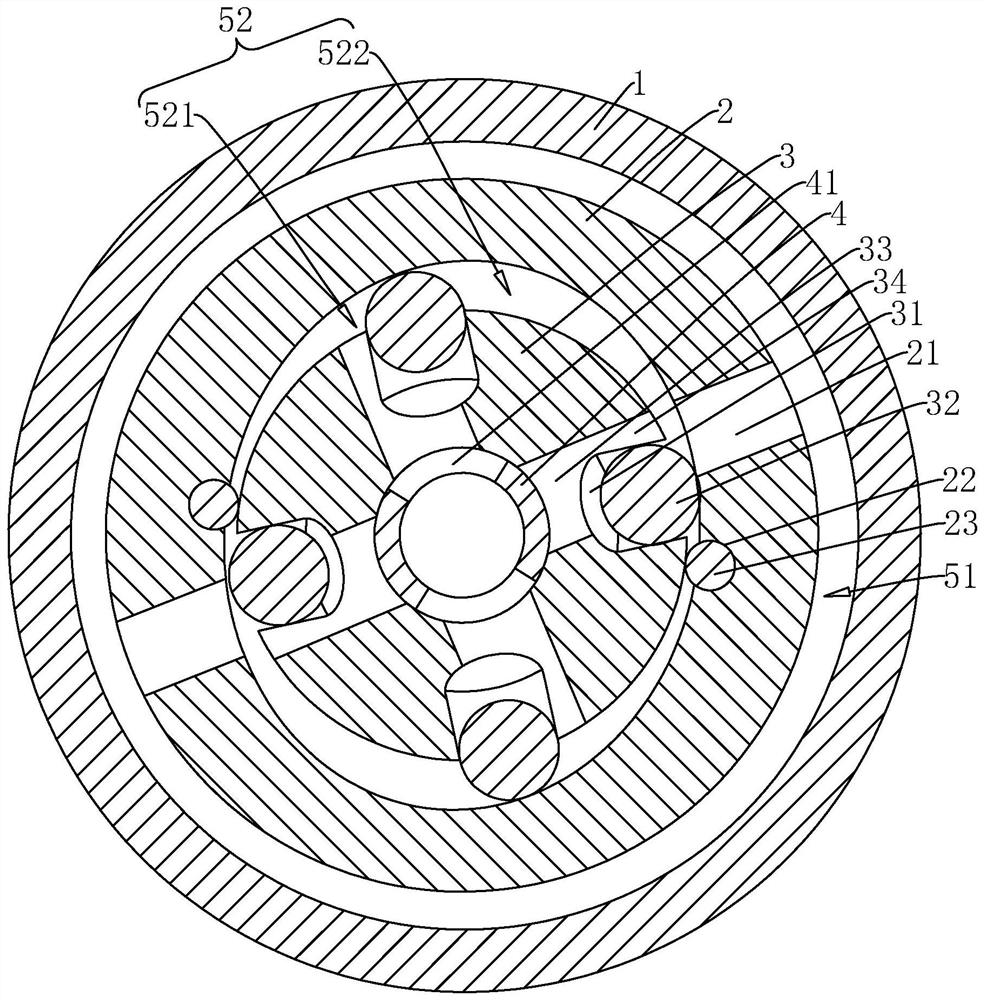

[0041] The embodiment of the present application discloses an all-metal dynamic seal concentric supporter downhole volume motor. refer to figure 1and figure 2 The downhole volume motor includes a vertically arranged outer tube 1 , a cylindrical stator 2 fixed in the outer tube 1 , a rotor 3 rotatably connected in the stator 2 , and a distribution shaft 4 suspended in the inner hole of the rotor 3 . The inner cavity of the stator 2 is elliptical, and the outer tube 1 and the stator 2 do not contact each other to form an annular cavity 51 .

[0042] refer to figure 2 and image 3 , the upper end of the distribution shaft 4 is connected with the external drilling fluid, so that the external drilling fluid can smoothly enter the inner hole of the distribution shaft 4, and a plurality of distribution holes 41 for the drilling fluid to flow out are also opened on the distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com