Cement slurry rotational flow generator mud cake scraping rotational flow type centralizing tool

A swirl generator and cement slurry technology, applied in cleaning appliances, drilling equipment, wellbore/well components, etc., can solve problems such as inability to scrape mud cakes, casing stuck, etc., and achieve time-saving and stable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing:

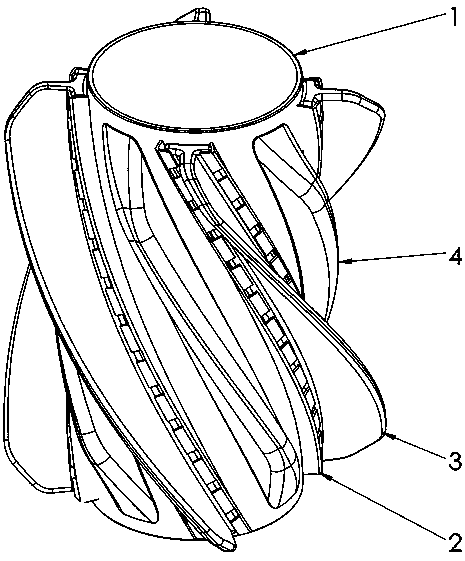

[0011] Depend on figure 1 As shown, a slurry swirl generator mud cake scraping swirl type righting tool includes an outer sleeve 1, and a rubber screw wing seat 2 and a rigid screw wing 4 are fixed on the outer wall of the outer sleeve 1. The rubber helical wing seat 2 is fixed with a rubber helical wing 3 . The rubber helical wing seat 2 and the rigid helical wing 4 are all four, and are fixed on the outer sleeve 1 at intervals, wherein the rigid helical wing 4 is welded on the outer sleeve 1 . The rubber spiral wing seat 2 includes a left base and a right base, the left base and the right base are L-shaped in cross-section, and are symmetrically welded on the outer sleeve 1 to form a slideway. The section of the rubber helical wing 3 is T-shaped, and its bottom edge is placed in the above-mentioned slideway and fixed by screws. The rubber helical wing seat 2 and the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com