Zero band beam layer cutting device and using method thereof

A belt layer cutting technology, applied in the field of zero-degree belt layer cutting device, can solve the problems of affecting product quality, complicated operation, and impossible completion of the plan, and achieve the effect of improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

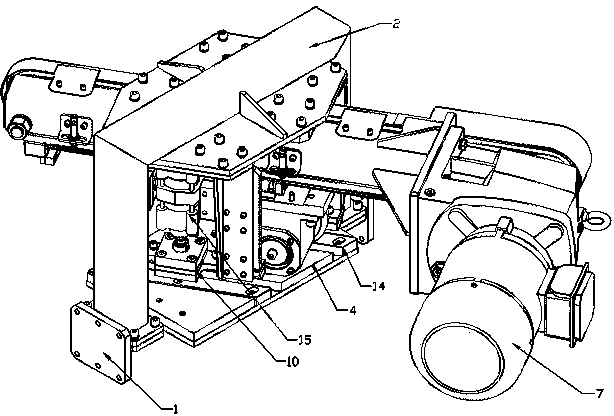

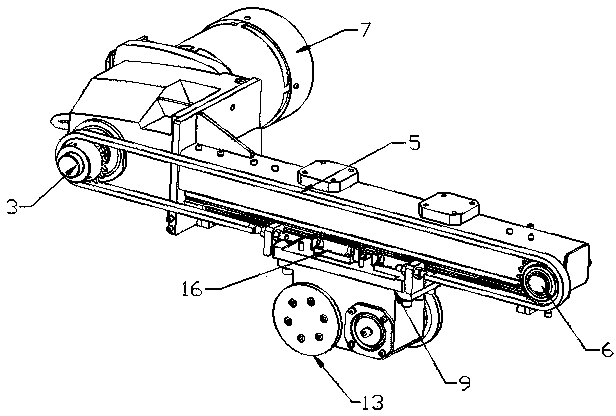

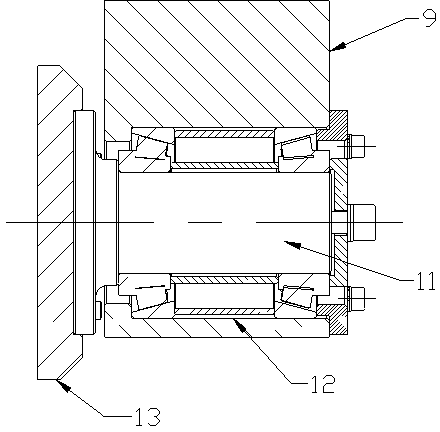

[0022] Such as figure 1 As shown, a zero-degree belt layer cutting device includes a frame, a drive mechanism installed on the frame, and a cutter assembly controlled by the drive mechanism to slide; at least two disc hobs 13 are installed on the cutter assembly.

[0023] The frame includes a cutter base frame 1 and a mounting frame 2 installed on the cutter base frame 1 .

[0024] The cutting device also includes a fixed assembly for fixing zero-degree belt layer movement, and the fixed assembly is installed on the mounting frame; the fixed assembly includes a cylinder 15 mounted on the mounting frame, and a pressure plate 10 controlled by the cylinder 15 to lift.

[0025] The cutting device also includes a knife slot that cooperates with the disc hob 13 for cutting, and the knife slot is located below the disc hob 13; The secondary cutter plate 14 is formed; the composition material of the knife groove can be changed according to the actual situation, as long as its functio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com