Powder material loading device with dynamic rapid discharging function

A technology of powder materials and shipping devices, which is applied in the direction of transportation and packaging, conveying bulk materials, conveyors, etc., can solve the problems of serious waste, dust flying all over the sky, and slow release of pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

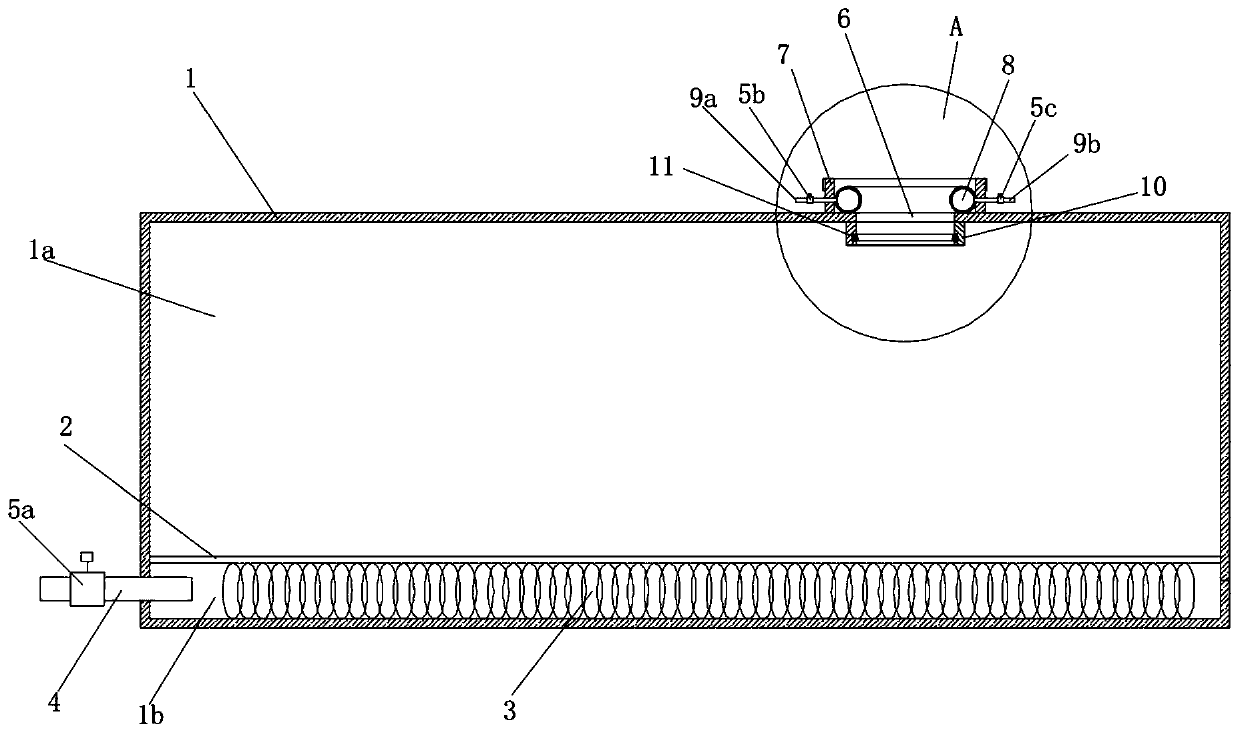

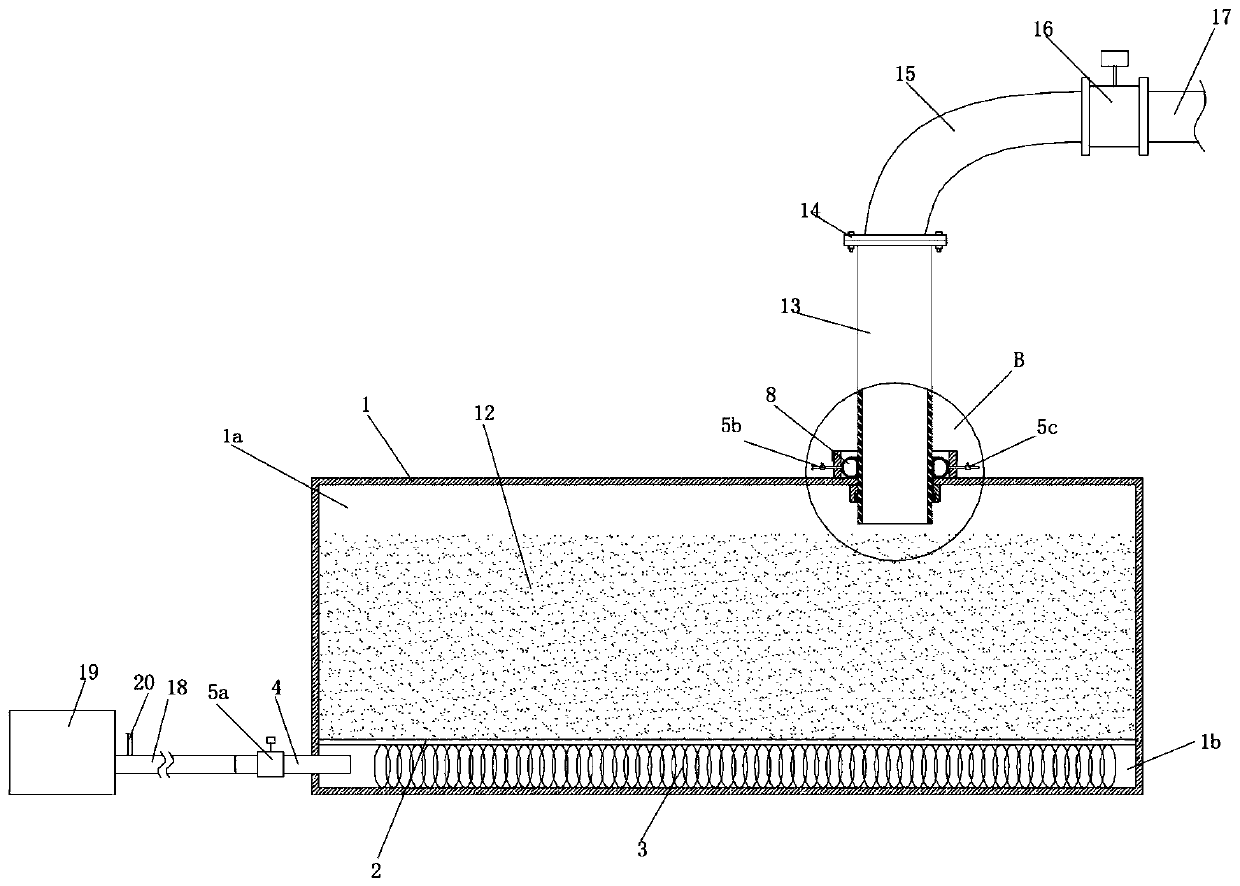

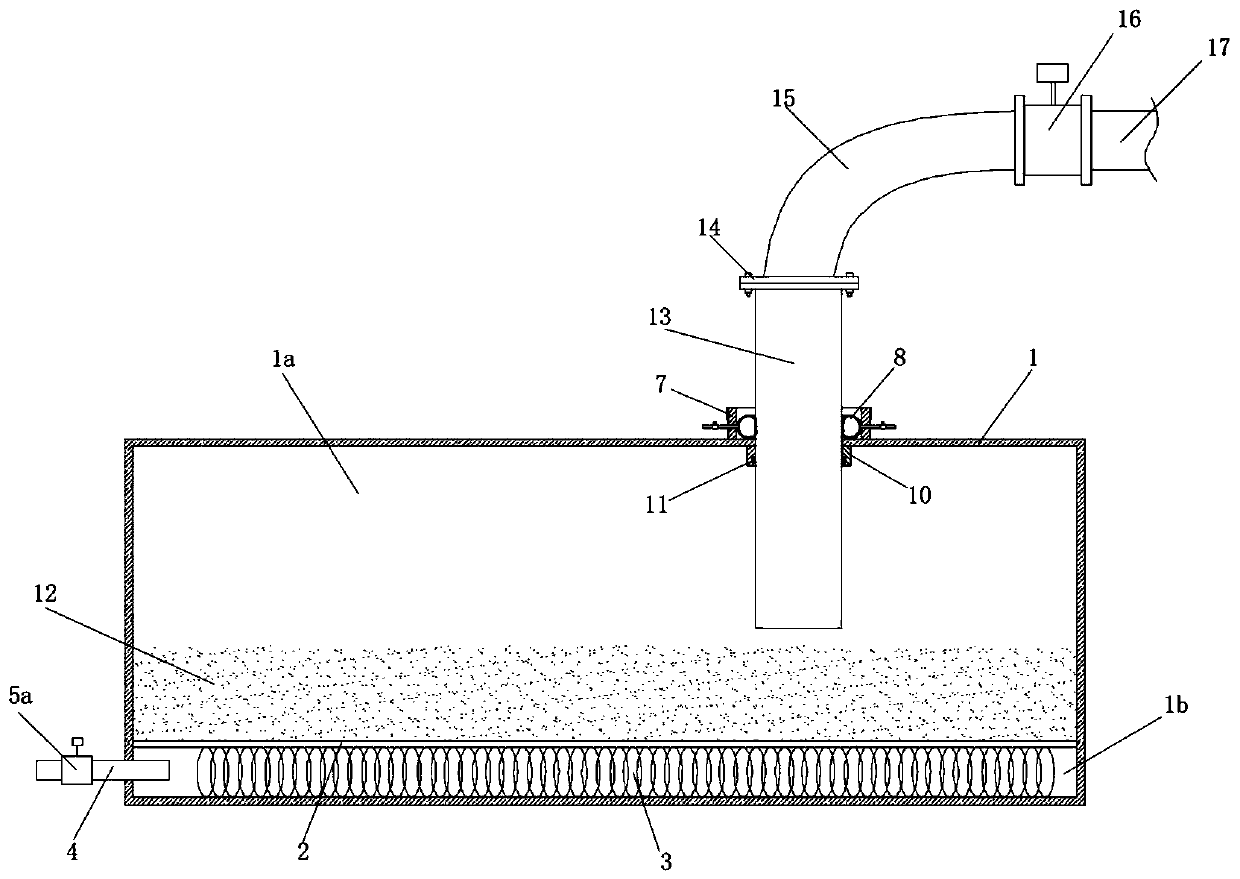

[0022] Depend on Figure 1-8 Given, the present invention comprises box body 1, and box body 1 is the hollow structure that airtight material is made, and the lower part of box body 1 is provided with air-permeable layer 2, and air-permeable layer 2 separates the inside of box body 1 into the upper material warehouse 1a and the lower inflatable bin 1b, the side wall of the box body 1 where the inflatable bin 1b is located is connected with an inflatable pipeline 4 communicated with its inner cavity, the inflatable pipeline 4 is provided with a first valve 5a, and the material bin 1a is located The top of the box body is provided with an internally and externally connected feed port 6, and a slidingly connected discharge pipeline 13 is mounted on the feed port 6, and an upwardly protruding annular airbag fixing edge 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com