Pump for dispensing a fluid material

A fluid product, dispensing pump technology, used in jet devices, inhalers, individual handheld devices, etc., to solve problems such as natural deformation and increased pressure drop in reservoirs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

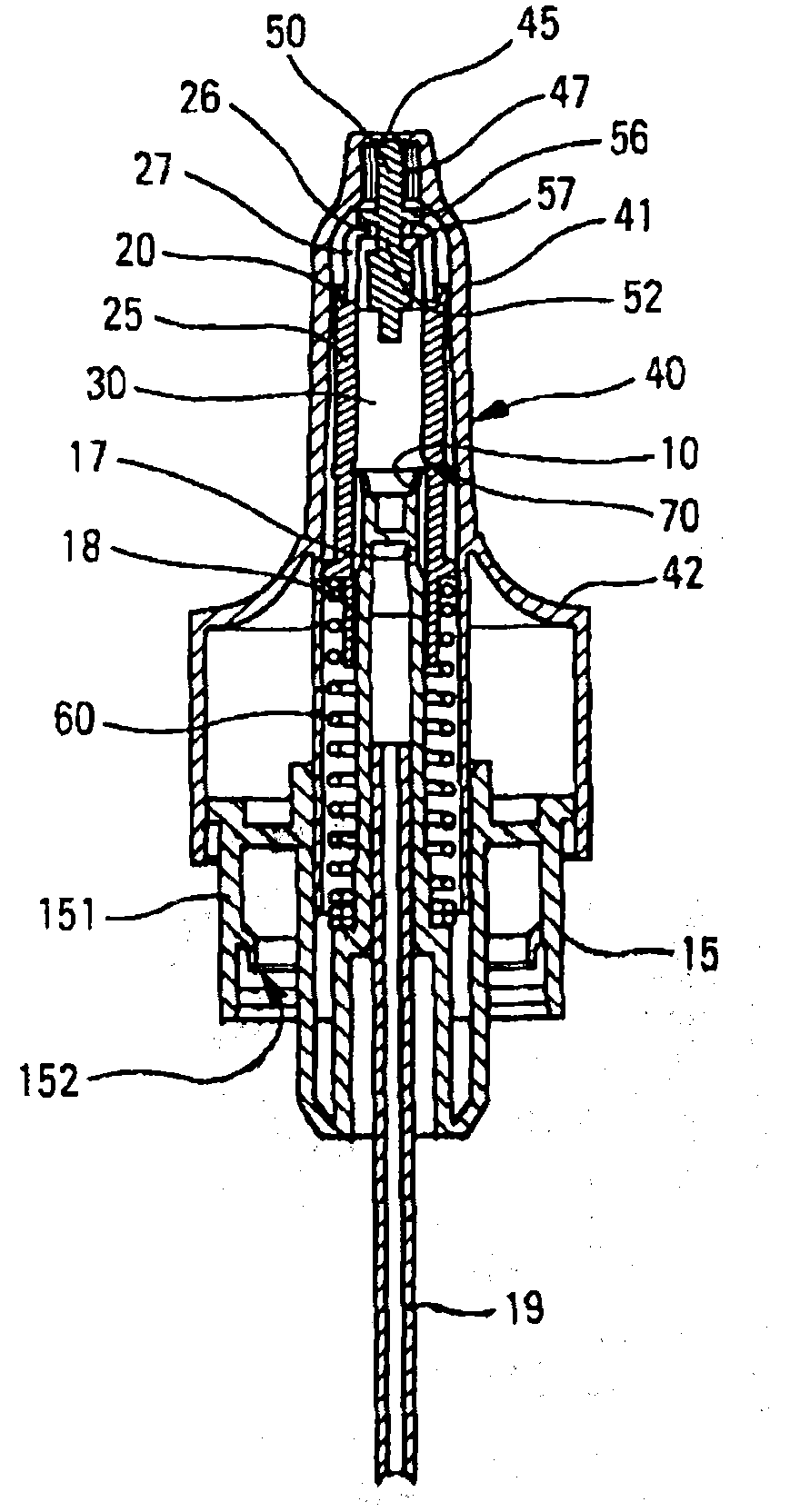

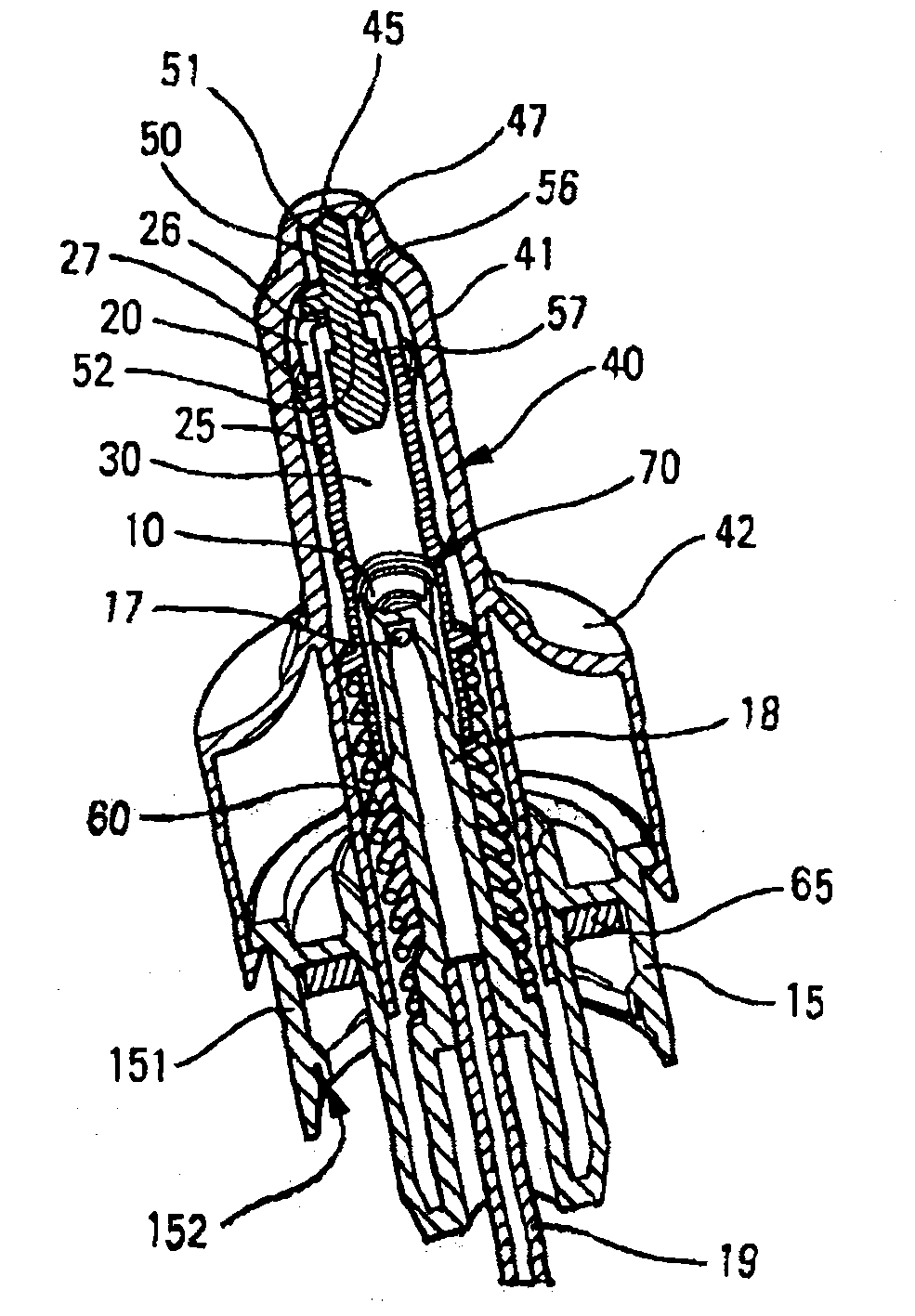

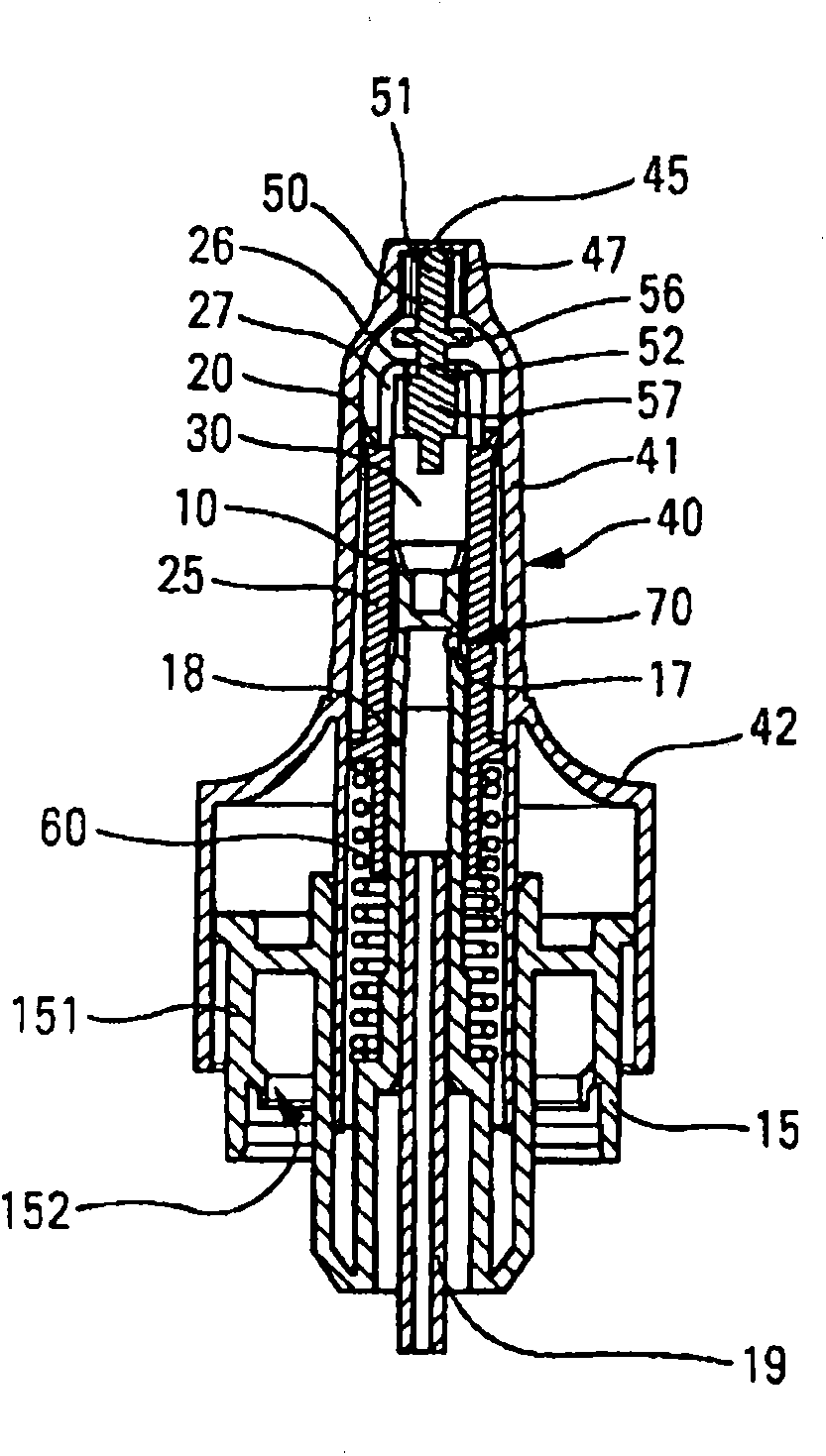

[0028] With reference to the figures, the fluid product dispensing device comprises a dispensing pump mounted on a reservoir (not shown) by means of a retaining ring 15 , advantageously interposed with a sealing gasket 65 . This retaining ring can be a crimp, twist or snap ring. A dispensing head 40 comprising a dispensing orifice 45 is provided for actuating said pump 10 . As shown in the drawings, the dispensing head may be a nose-shaped head with an elongated axial portion 41 intended to be inserted into the user's nostril, and the dispensing orifice is located in said elongated portion of the dispensing head. The downstream end of the long axial portion. A widened actuation portion 42 is provided for allowing the user to depress the dispense head with his finger to actuate the pump. Advantageously, the dispensing orifice is provided with a spray profile for dispensing the product in the form of a finely sprayed spray.

[0029] The dispensing pump comprises a first pisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com