Press for attaching nuts to pipes

A technology for stamping devices and pipes, applied in nuts, threaded fasteners, connecting components, etc., can solve problems such as lack of practicality, and achieve the effects of high-efficiency fixing, easy fixing, and automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

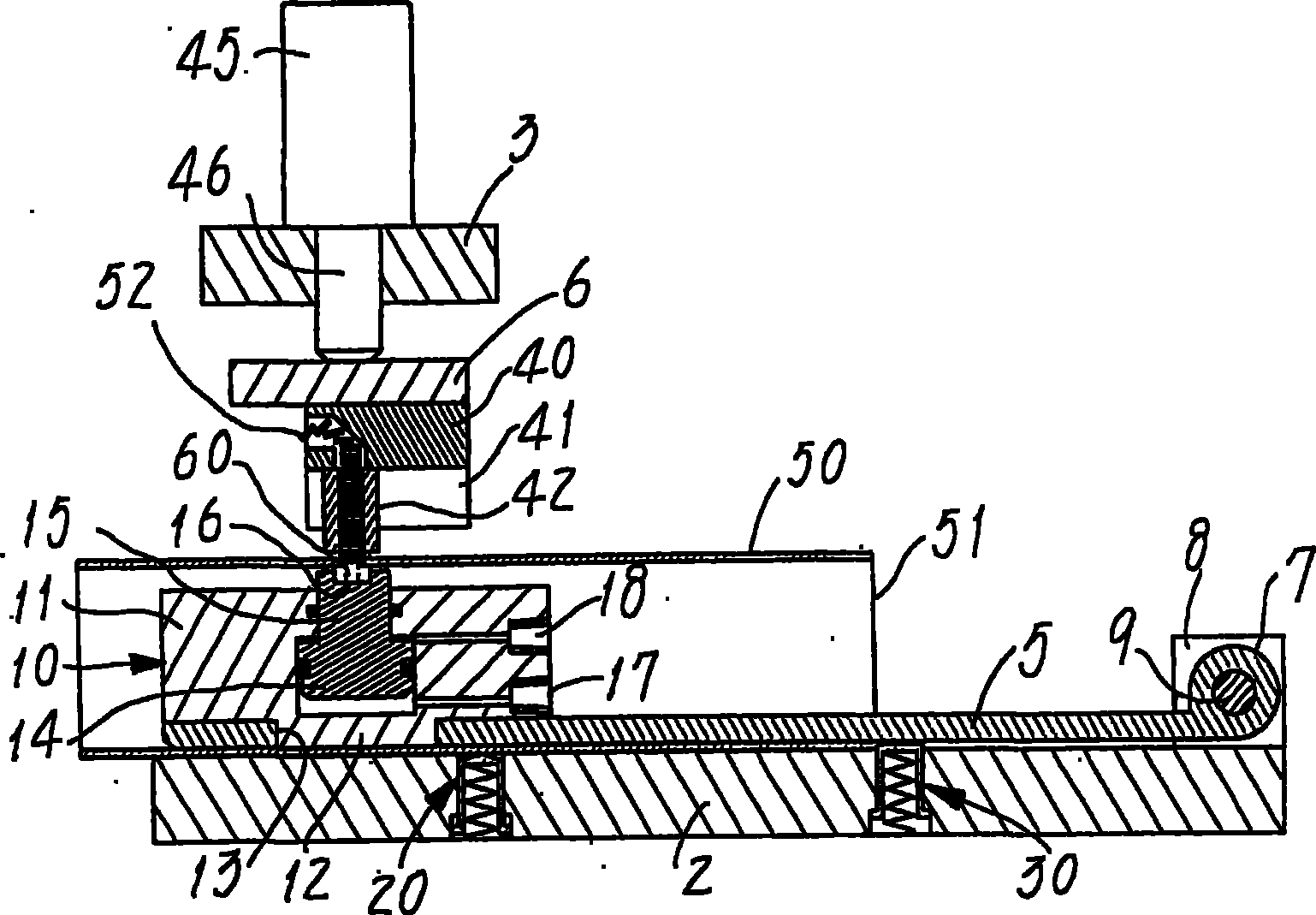

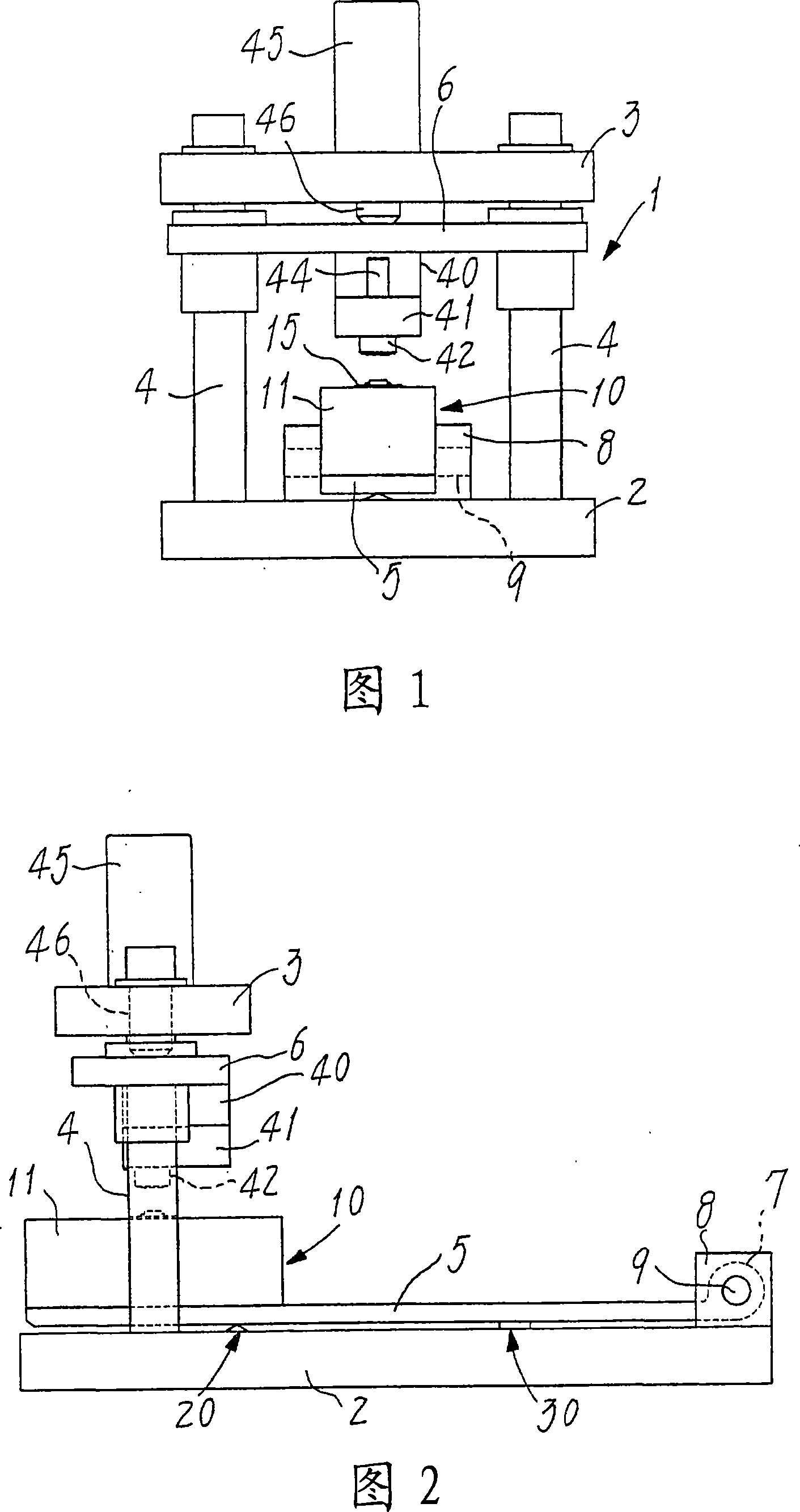

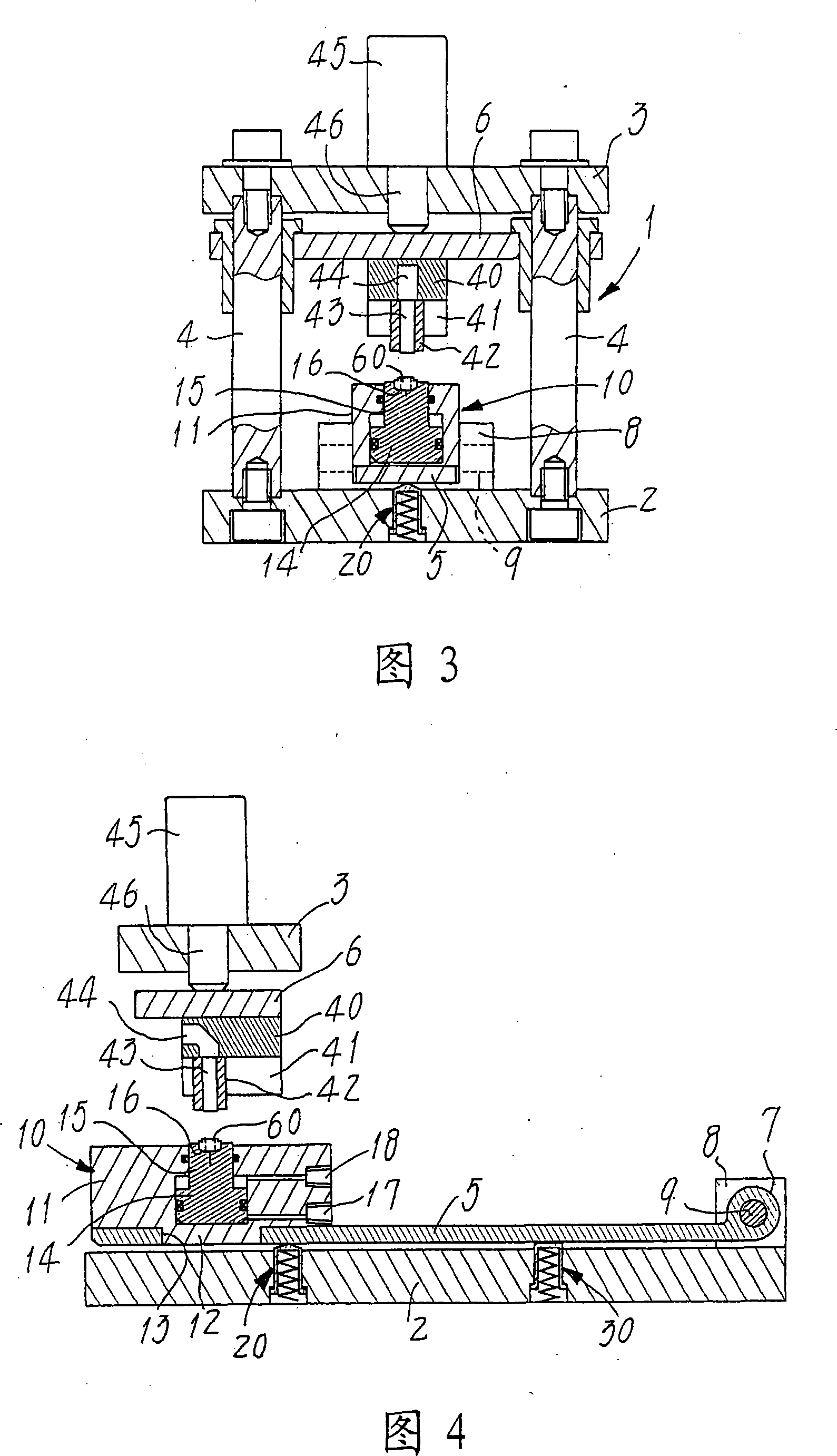

[0027] Embodiments of the present invention will be described below with reference to the drawings.

[0028] 1 to 4 show a punching device for fixing a nut on a pipe according to the present invention. The punching device is used to fix a piercing nut 60 to a metal square pipe 50 (see FIGS. 5 and 6 ) described later from the inside. The frame 1 of this punching device has such a structure: on both sides of the front end portion of the longer lower pedestal 2 extending in the front-rear direction, two guide columns 4, 4 are erected side by side. The upper end portion of 4 is fixedly supported with upper pedestal 3 .

[0029] On the lower pedestal 2, a strip-shaped movable support body 5 extending in the front-to-back direction is installed, and on the upper pedestal 3, a flat upper mold support body 6 is installed. , 4 are free to move in the up and down direction relative to the lower pedestal 2 .

[0030] The movable supporting body 5 is arranged on the lower base 2 in such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com