Compressor unit

A compressor and pressure technology, applied in engine components, pump components, electromechanical devices, etc., can solve the problems of the destruction of insulating parts, the explosive expansion of the suction medium, etc., to avoid channel blockage, improve practicability, and reduce complexity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

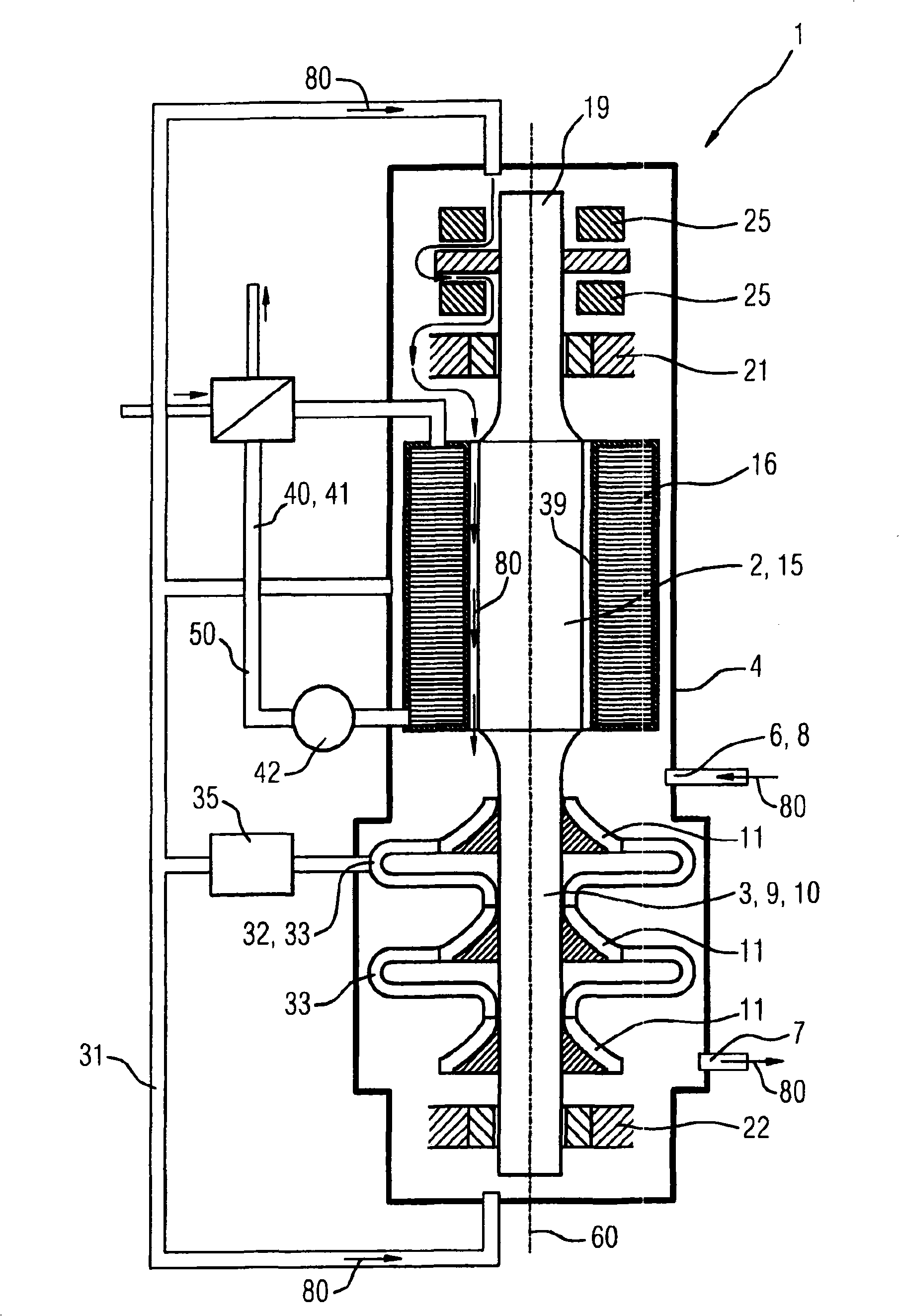

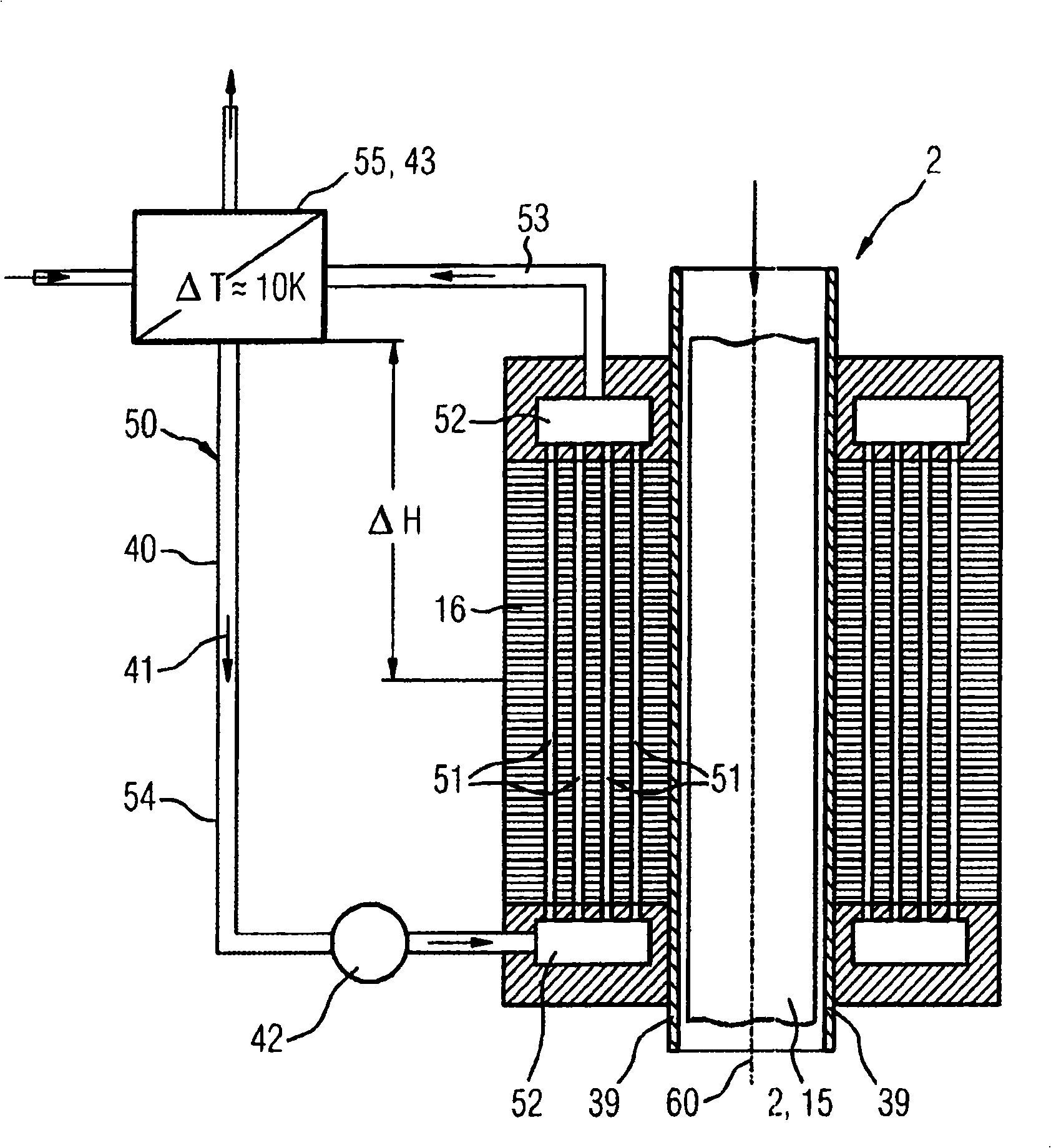

[0021] figure 1 A section through a compressor unit 1 according to the invention is shown schematically, which comprises, as essential components, a motor 2 and a compressor 3 in a gas-tight housing 4 . The housing 4 protects the motor 2 and the compressor 3 . The housing 4 is provided in the transition region from the motor 2 to the compressor 3 with an inlet 6 and an outlet 7 , through which the fluid to be compressed is sucked in via the inlet 6 by means of a suction connection 8 and the compressed fluid is allowed to flow through the outlet 7 Walk.

[0022] The compressor unit 1 is arranged vertically in operation, wherein the motor rotor 16 of the motor 2 is united by the compressor rotor 9 of the compressor 3 into a common shaft 19 , which rotates about a common vertical axis of rotation 60 .

[0023] The motor rotor 15 is supported in a first radial bearing 21 at the upper end of the motor rotor 15 .

[0024] The compressor rotor 9 is supported in a lower position by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com