Steam sterilizing device

A steam sterilization and cooling chamber technology, applied in food preservation, food science, heating, etc., can solve the problems of low temperature, incomplete preheating, and uneven preheating of the sterilization chamber, so as to ensure quality and preheat uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

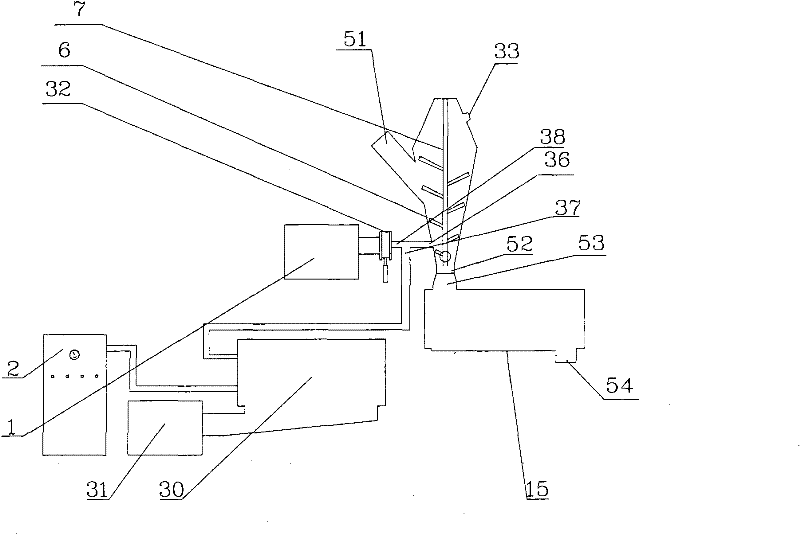

[0046] figure 1 A schematic diagram of the steam sterilizing device according to the present invention is provided, and it can be seen from the figure that the steam sterilizing device includes a sterilization chamber 6 and a cooling chamber 15; The feed inlet 51 and the sterilization chamber outlet 52 are also provided with a rotary agitator 7 inside, the drive of the rotary agitator 7 can be selected to use any power source, and the electric motor 12 is selected for driving in this embodiment; Through the rotation and agitation of the blades on the rotary agitator 7, the material to be sterilized is continuously stirred and lifted up during the sterilization process; a hot air inlet 36 is also provided on the sterilization chamber 6, and the hot air enters The tuyere 36 is provided with a first branch air inlet 38 and a second branch air inlet 37, the first branch air inlet 38 is connected with the first hot air induced draft fan 1 through a pneumatic valve 32, and the secon...

Embodiment 2

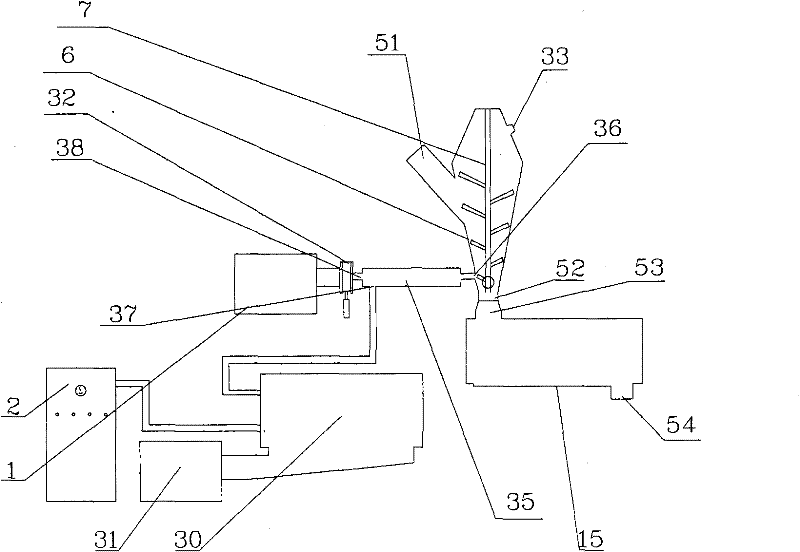

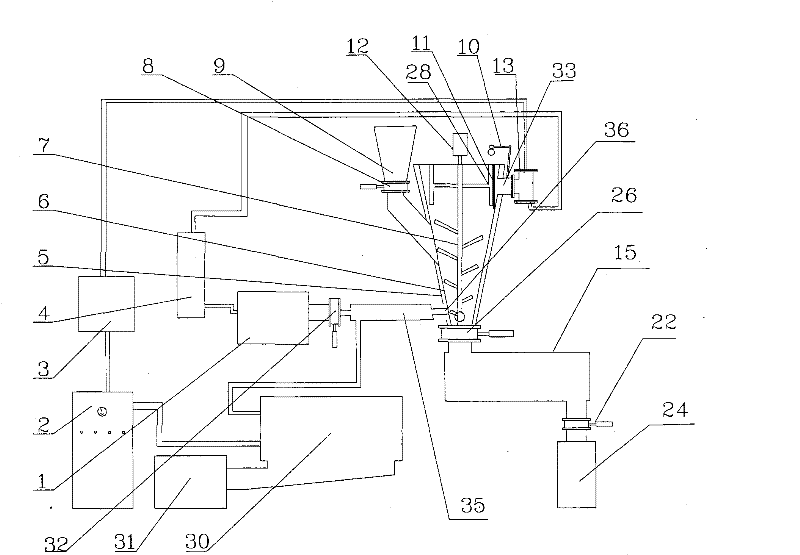

[0052] The steam sterilizer described in this embodiment is as image 3 As shown, it is provided with a sterilization chamber shell 5 that forms an interlayer with the sterilization chamber 6 on the sterilization chamber 6, and fills the insulation medium in the interlayer, thereby reducing the process of the sterilization chamber at high temperature as much as possible. Neutralize the external energy exchange, thereby reducing the loss of high temperature and reducing energy consumption. Moreover, a feed hopper 9 is further provided at the feed port 51 of the sterilization chamber, and the feed hopper 9 and the feed port 51 of the sterilization chamber are connected through a pneumatic valve 8 at the feed port, thereby facilitating the addition of materials. Similarly, a discharge port pneumatic valve 26 can also be set between the sterilization bin discharge port 52 and the cooling bin feed port 53 to control the sterilized material to be transferred from the sterilization b...

Embodiment 3

[0059] Figure 4 Another embodiment of a steam sterilizer is shown.

[0060] Compared with the steam sterilizing device in Example 2, in the steam sterilizing device described in this embodiment, the setting of the filter screen 11 can not only correspond to the gas discharge port 33 inside the sterilization chamber 6 In order to avoid the dense dispersion of materials at the position of the sterilization chamber 6 when the airflow flows out from the gas discharge port 33, in this embodiment, at the position of the gas discharge port 33, along the A circle of filter screen 11 is set inside the bin 6, so that the materials carried in the airflow discharged through the gas discharge port 33 or the materials that may be attached to the inner wall of the sterilization bin 6 during the stirring and sterilization process may flow with the airflow. The material is collected on the filter screen 11 as much as possible to reduce its loss. In order to better realize the recovery of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com