Gas purifying and water removing device used in CNG dispenser

A filling machine and gas cleaning technology, which is applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems of affecting gas filling efficiency, increasing the space volume of pipeline filters, and high after-sales repair costs, so as to ensure heat exchange effect, Improve heat exchange efficiency, facilitate installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] For the convenience of those skilled in the art to understand, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

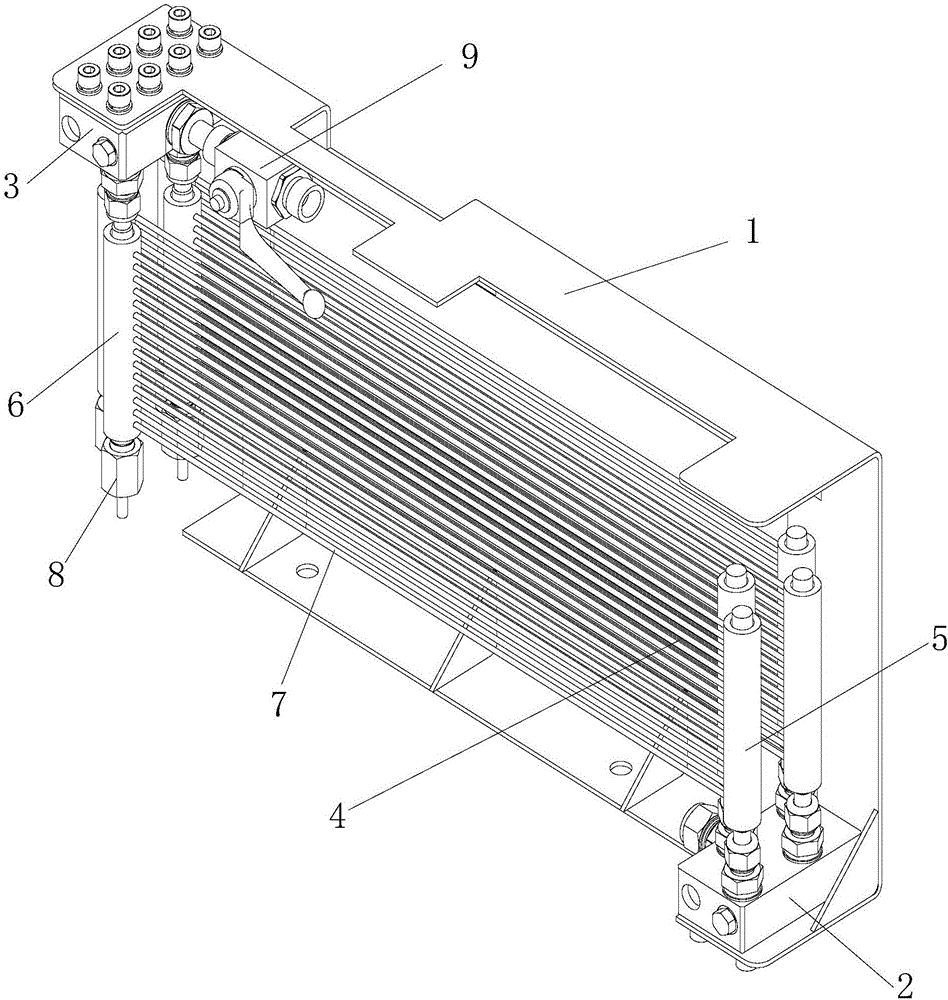

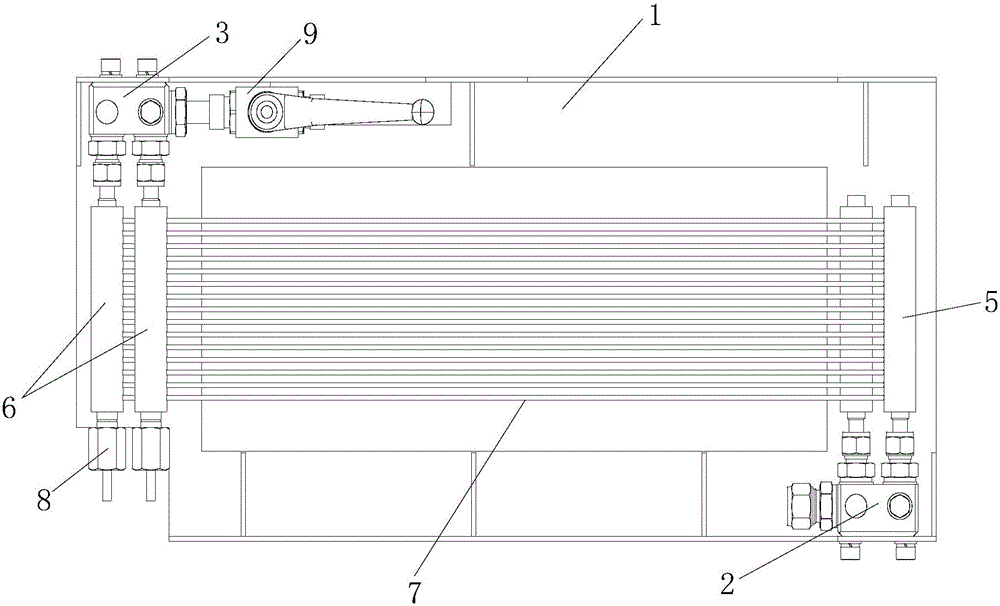

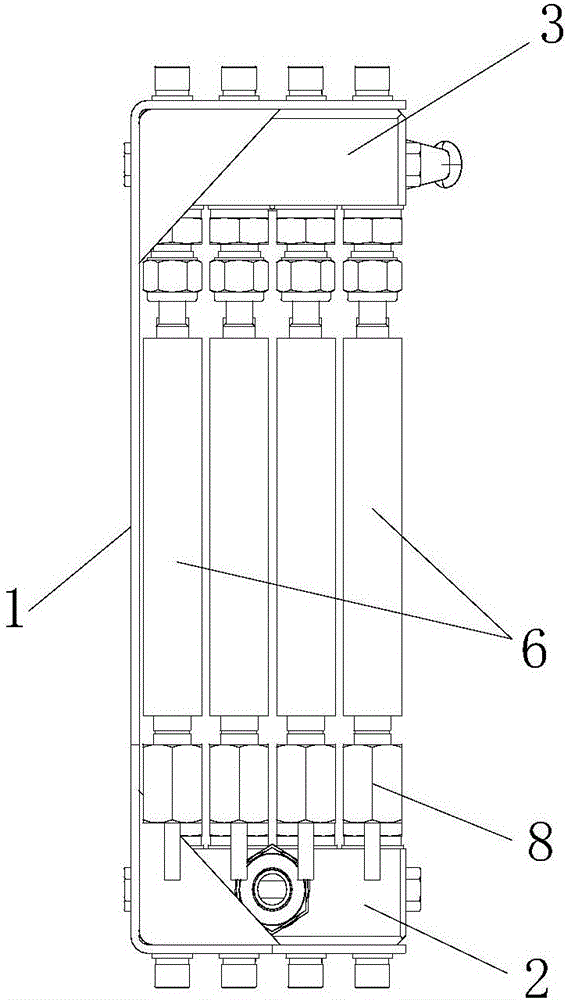

[0019] Such as Figure 1 to Figure 3 As shown, the air purification and dehydration device used for CNG filling machines includes an outer frame 1, an air inlet valve 2, an air outlet valve 3 and a plurality of condensed air purification components 4, the air inlet valve 2 and the outlet valve The gas port valves 3 are all installed on the outer frame 1; the condensed air purification assembly 4 includes an air inlet pipe 5, an air outlet pipe 6 and a plurality of heat dissipation capillary tubes 7, the lower end of the air inlet pipe 5 is connected with the air inlet valve 2, and the outlet The upper end of the trachea 6 is connected with the air outlet valve 3, and the plurality of heat dissipation capillary tubes 7 are arranged in a row from top to bottom, and one end of the plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com