High-flux filter method of composite polyphase catalysis materials

A technology of heterogeneous catalysis and screening methods, applied in chemical instruments and methods, analytical materials, radiation pyrometry, etc., can solve problems such as difficult comparisons and imperfect methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

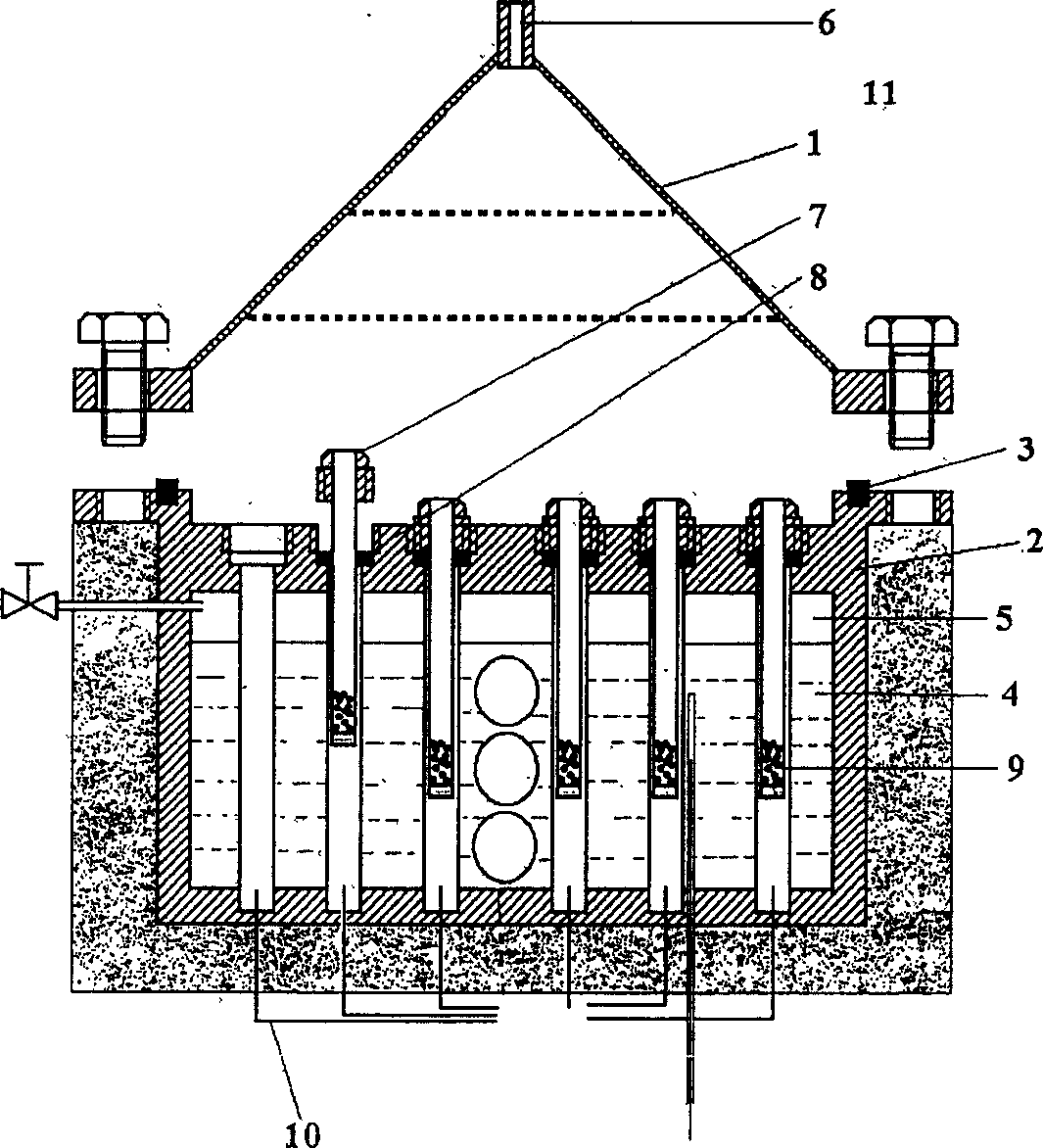

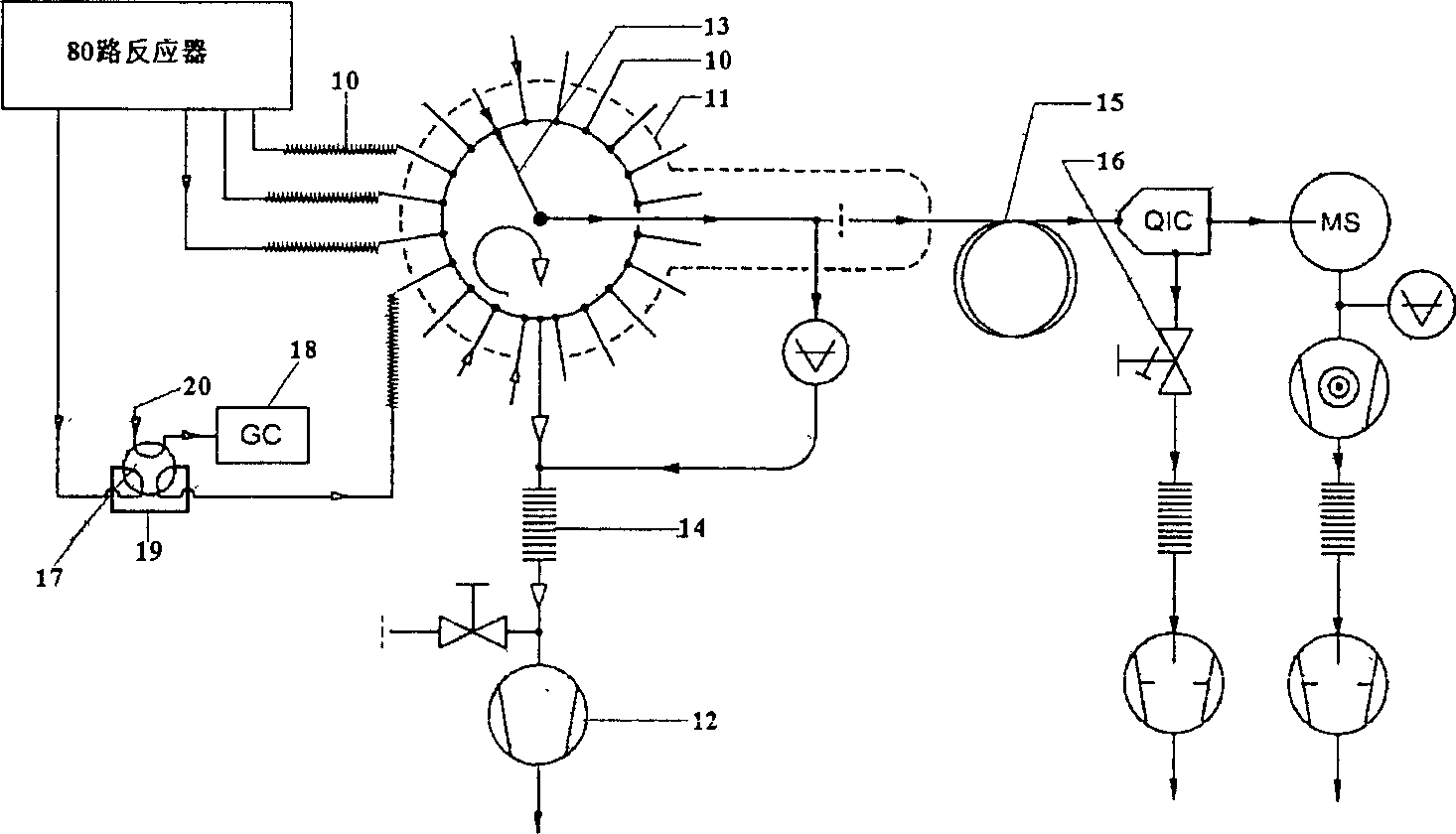

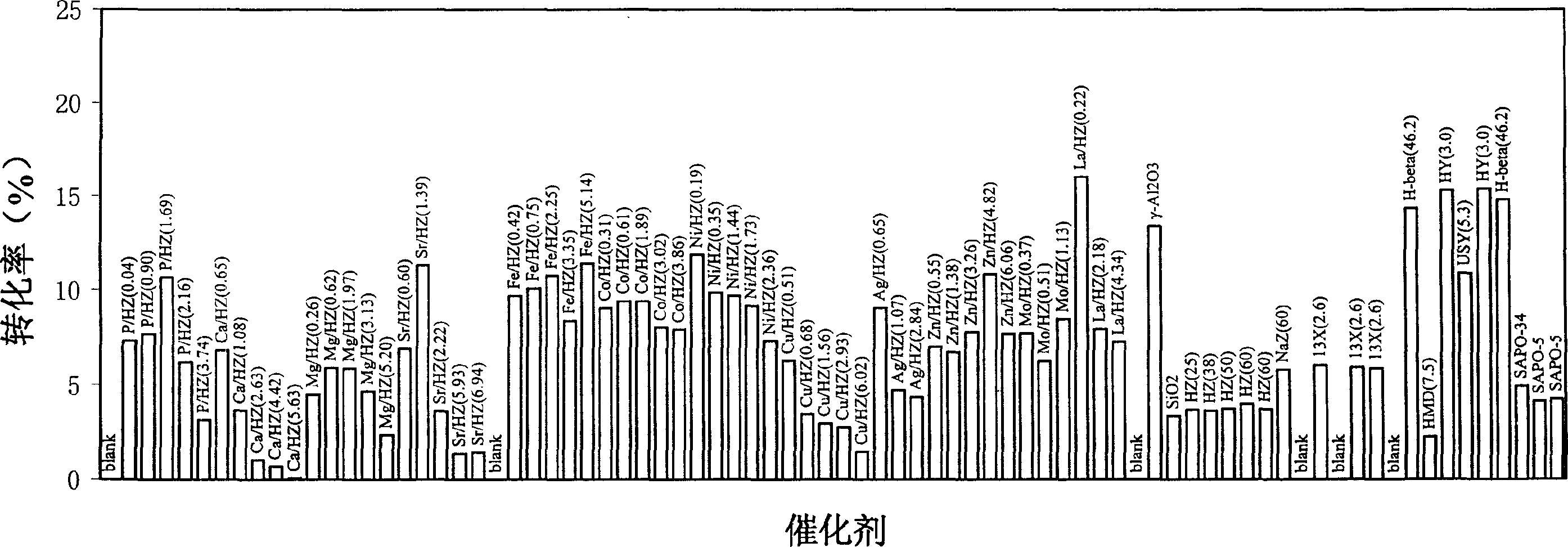

[0025] For the device used in this example, see figure 1 and figure 2 . The self-condensation reaction of acetone was investigated. The condensation reaction of acetone is as follows:

[0026]

[0027] In order to verify the feasibility and accuracy of the method, some reaction tubes were filled with the same catalyst, while some reaction tubes were filled with quartz sand for blank comparison. The loading amount of the catalyst was 0.3 g on average. The reaction tube containing the catalyst was loaded into the combined reaction furnace (in this experiment, the combined reaction furnace used was 80 channels), sealed with flexible graphite, and tightened. The upper cover was sealed, argon gas was introduced, and the temperature was raised to 550° C. and kept for 2 hours. After the activation is completed, lower to the reaction temperature (250°C), and use a feed pump to pump acetone into the preheating tube (the temperature of the preheating tube is 300°C), so that the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com