Integrated expansion kettle, cooling system and automobile

An expansion kettle, an integrated technology, is used in the cooling of engines, machines/engines, mechanical equipment, etc., and can solve the problems of the expansion kettle without gas-liquid separation function, abnormal sound inlet and outlet temperature difference, and low gas-liquid separation process efficiency. To achieve the effect of reducing temperature difference, reducing degassing time, and reducing heat leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

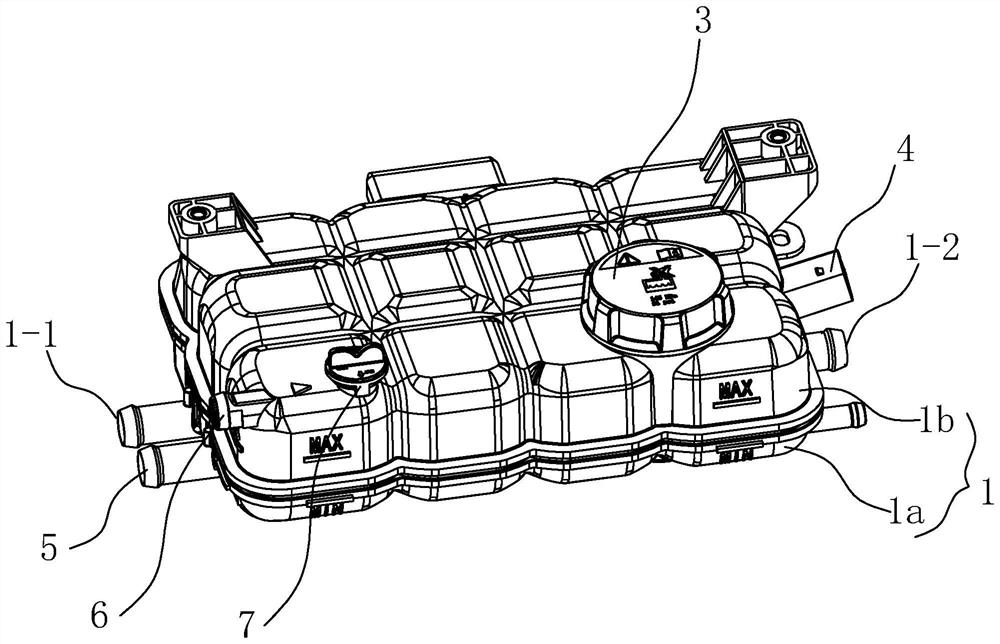

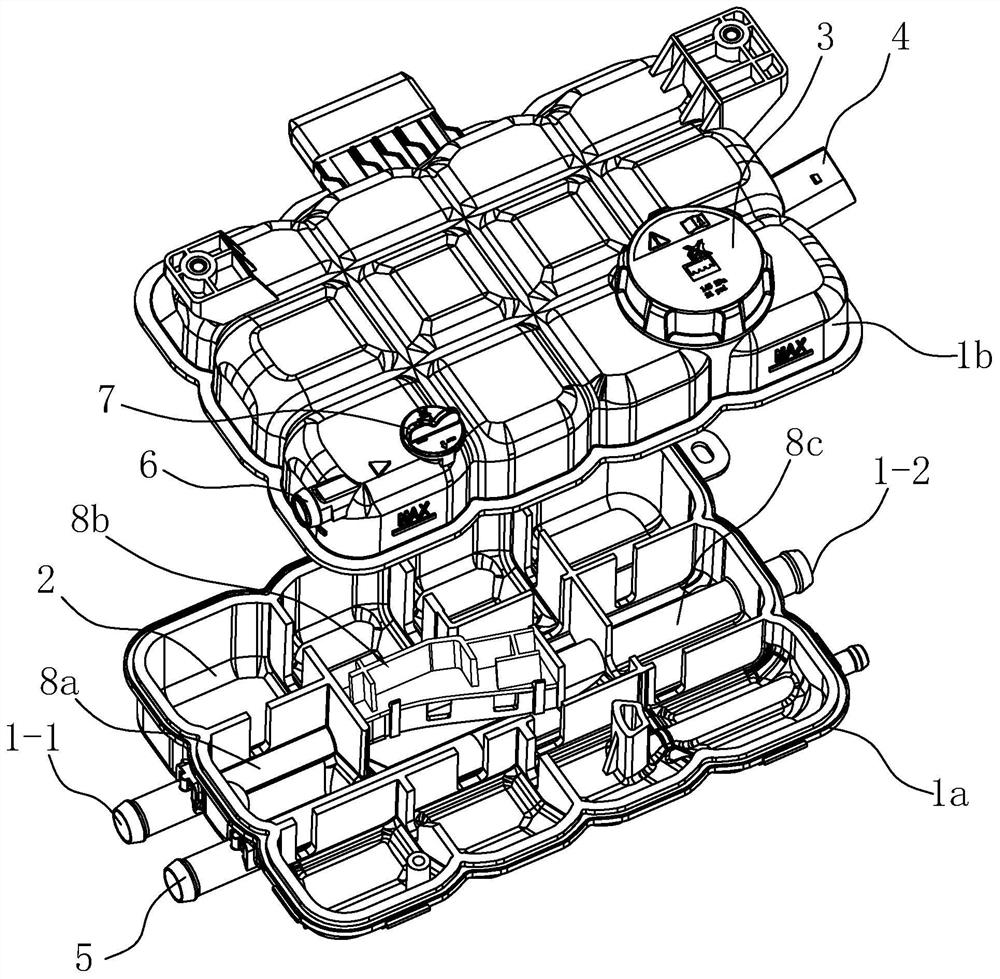

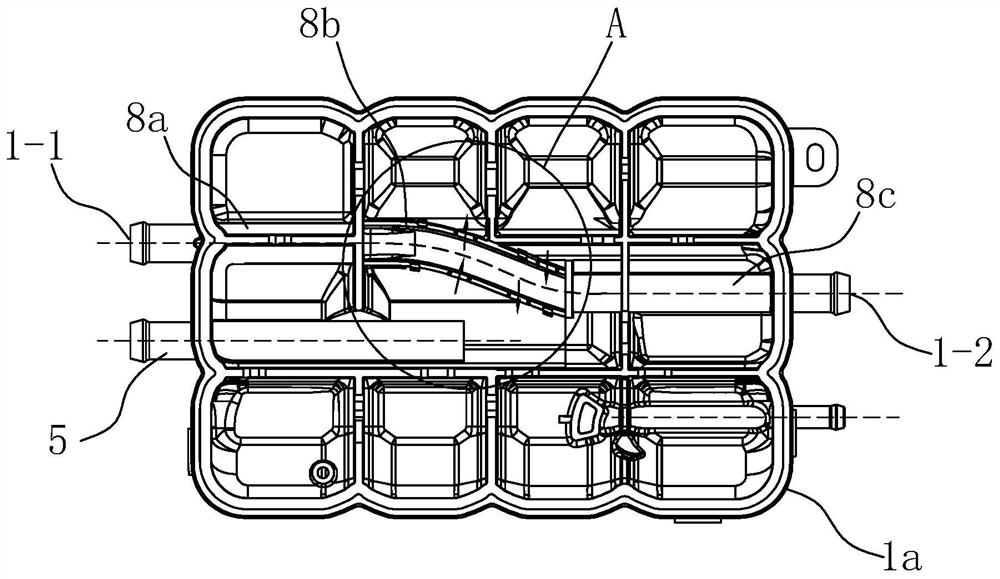

[0045] Please see attached figure 1 and 2 : An integrated expansion kettle, a cooling system and an automobile, including a kettle body 1, the interior of the kettle body 1 is provided with a chamber 2 for containing liquid, and the kettle body 1 is provided with a liquid inlet 1-1 and an outlet Liquid ports 1-2, the kettle body 1 includes a lower kettle body 1a and an upper kettle cover 1b, the shape of the kettle body 1 can be designed according to the installation space, and is not limited to the shape of the solution of the present application. The kettle body 1 is provided with a pressure relief valve 3 and a liquid level sensor 4 .

[0046] For details, please refer to the appendix figure 1 and 2 : The kettle body 1 is also provided with a motor refilling port 5, a degassing liquid inlet 6 and an after-sales switch 7, and the degassing and liquid inlet 6 is connected to the after-sales switch 7 and controls the degassing and liquid inlet 6 through the after-sales swit...

Embodiment 2

[0054] see Figure 7 : A cooling system provided by the technical solution of this embodiment includes a motor cooling circuit, a battery cooling circuit, and the expansion kettle in Embodiment 1.

[0055] To sum up, an integrated expansion kettle and a cooling system are provided by the technical solutions of the first and second embodiments. The expansion kettle integrates the gas-liquid separation function, and is communicated with the liquid inlet and the liquid outlet of the kettle body 1 at the same time. The battery cooling circuit 16 is connected to the motor cooling circuit 17 through the motor liquid replenishment port 5 and the degassing liquid inlet 6. The motor cooling circuit 17 and the battery cooling circuit 16 share an expansion kettle, and the single kettle replaces the double kettle, and there is no need to set up a special external The gas-liquid separator is integrated with the aftermarket switch 7. As a whole, the number of expansion kettles and liquid l...

Embodiment 3

[0058] Please see attached Figure 8 : This embodiment provides an alternative solution for an integrated expansion kettle. Based on Embodiment 1, the fluid direction changing portion 12 may be a bending section, the first opening 13 is located on the inward bending side of the bending section, and the The second opening 14 is located on the outwardly curved side of the bending section, thereby forming a pressure difference between the first opening 13 and the second opening 14, so that the second opening 14 in the cooling liquid flow channel 8 performs liquid discharge, and the first opening 13 performs liquid replenishment .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com