Separation method of industrial mixed sylvite

A separation method and potassium salt technology are applied in the direction of alkali metal fluoride, alkali metal halide purification, alkali metal chloride and other directions, which can solve the problems of difficult application in industrialized production, difficulty in solvent recovery, large solvent consumption, etc., and achieve recycling and utilization. High efficiency, strong operability, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

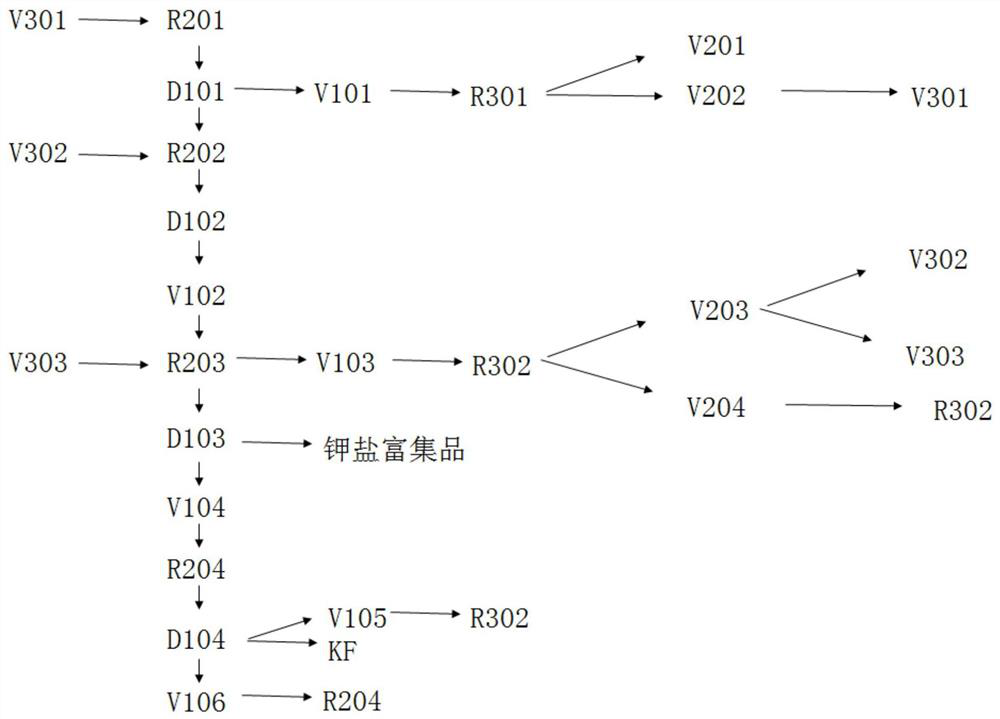

Method used

Image

Examples

Embodiment 1

[0062] Add 150 g of by-product mixed potassium salts and 300 g of sulfolane to a 500 mL four-necked bottle, incubate at 90° C. for 2 hours, and filter to obtain 151.0 g of crude mixed potassium salts (dry weight 135.9 g). After testing: Wt(KCl)%=88.19%, Wt (KF)%=10.89%, Wt (water)%=0.21%, then it is dissolved with 231.6g 90 ℃ of hot water, after dissolving completely, cool down to 60 ℃, then slowly add 271.8g methanol, crystallize (terminal temperature 15 ℃), suction filtration, the filter cake is rinsed with a small amount of methanol, and dried to obtain 104.1g of potassium chloride dry product, appearance: white crystal, after testing: Wt(KCl)%=99.30%, Wt(KF)%=0.23 %, Wt (water)%=0.15%; 535.8g filtrate after the above-mentioned crystallization is concentrated under reduced pressure, after being concentrated to the content of initial mixed potassium salt is 90%, add 31.8g methyl alcohol, crystallization (terminal temperature 15 ℃), Suction filtration, the filter cake is rins...

Embodiment 2

[0064] Add 150 g of by-product mixed potassium salts and 300 g of dichloromethane into a 500 mL four-necked bottle, incubate at 40° C. for 2 hours, and filter to obtain 150.1 g of crude mixed potassium salts (dry weight 135.1 g). After testing: Wt(K Cl)%=88.78 %, Wt(KF)%=10.88%, Wt(water)%=0.15%, then it is dissolved with 232.3g 90 ℃ of hot water, after dissolving completely, cool down to 60 ℃, slowly add 270.2g methyl alcohol afterwards, crystallization ( End point temperature 15°C), suction filtration, filter cake rinsed with a small amount of methanol, dried to obtain 103.3g potassium chloride dry product, appearance: white crystal, after testing: Wt(KCl)%=99.36%, Wt(KF) %=0.06%, Wt (water)%=0.06%; 534.3g filtrate after above-mentioned crystallization is concentrated under reduced pressure, after being concentrated to the content of initial mixed potassium salt is 90%, add 31.8g methyl alcohol, crystallization (terminal temperature 15°C), suction filtration, the filter cake...

Embodiment 3

[0066] Add 150 g of by-product mixed potassium salts and 300 g of toluene to a 500 mL four-necked bottle, incubate at 90° C. for 2 hours, and filter to obtain 154.0 g of mixed potassium salt crude product (dry weight 135.5 g). After testing: Wt(KCl)%=88.56%, Wt (KF)%=10.98%, Wt (water)%=0.31%, then it is dissolved with 232.6g 90 ℃ hot water, after dissolving completely, cool down to 60 ℃, then slowly add 271.0g methanol, crystallize (terminal temperature 15 ℃), suction filtration, the filter cake is rinsed with a small amount of methanol, and dried to obtain 103.7g potassium chloride dry product, appearance: white crystal, after testing: Wt(KCl)%=99.34%, Wt(KF)%=0.06 %, Wt (water)%=0.06%; 535.4g filtrate after above-mentioned crystallization is concentrated under reduced pressure, after being concentrated to the content of initial mixed potassium salt is 90%, add 31.8g methanol, crystallization (terminal temperature 15 ℃) , suction filtration, the filter cake is rinsed with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com