Device for automatically removing fluid impurities in pipelines

An automatic removal and internal fluid technology, applied in the fields of filtration and separation, separation methods, chemical instruments and methods, etc., can solve problems such as affecting the fluid flow in the pipeline, and achieve the effect of improving the blocking efficiency without affecting the flow rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

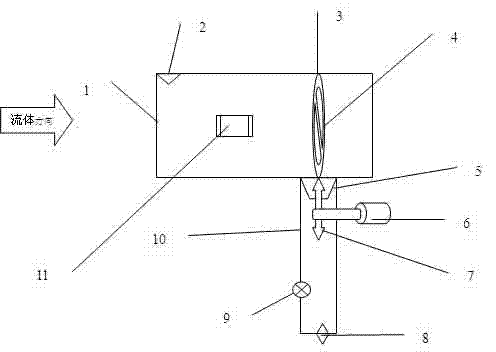

[0019] see figure 1 and figure 2 The shown device for automatically removing fluid impurities in pipelines includes a cylindrical shell 1, a rectangular shell 10 vertically connected to and communicated with the cylindrical shell;

[0020] An impurity and floating matter sensor 2 is arranged on the inner wall of the left part of the cylindrical housing 1, and the impurity and floating matter sensor is connected with the PLC controller 11 arranged outside the cylindrical housing 1 to sense impurities and floating matter. The signal of the object is transmitted to the PLC controller;

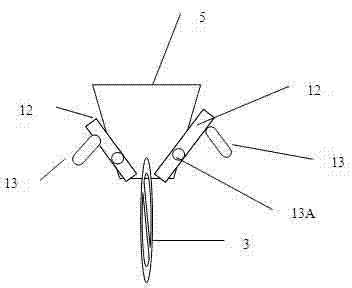

[0021] A closed card mechanism 5 is set in the rectangular shell 10, close to the connecting part of the rectangular shell and the cylindrical shell;

[0022] An arresting net 3 passes through the airtight card mechanism 5, and a transmission rod 7 is connected to the bottom of the arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com