Rolling wheel sliding rail driving device of rail transit platform gate

A rail transit and driving device technology, which is applied to the suspension device of the wing leaf, door/window accessories, power control mechanism, etc., can solve the problems of strict installation accuracy, high maintenance cost, and large running resistance, etc., and achieve improved Running stability, improving efficiency and reducing running resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

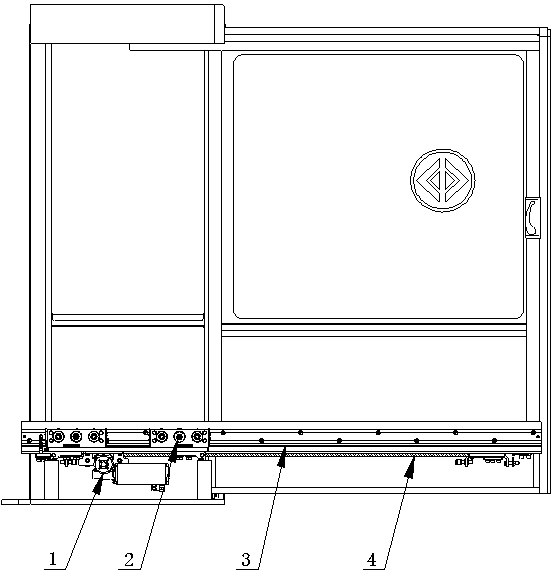

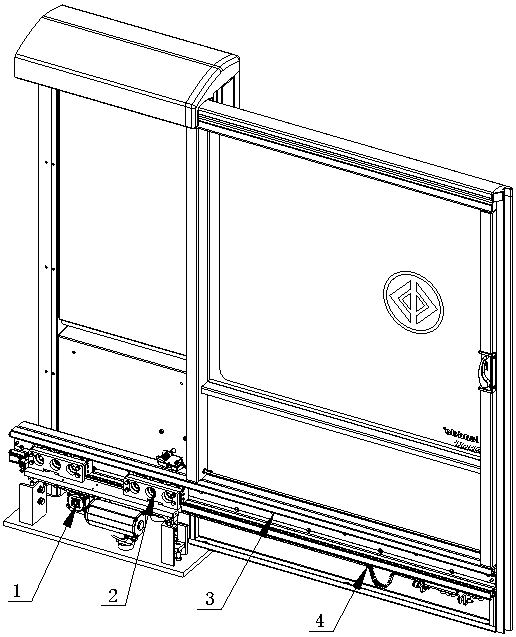

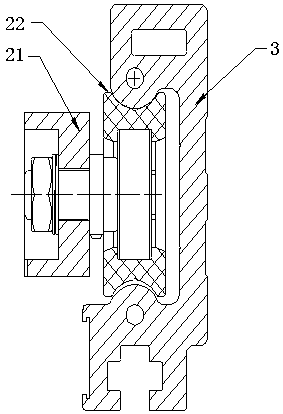

[0028] Such as Figure 1 to Figure 7 As shown, the embodiment of the present invention provides a roller slide rail driving device for a rail transit platform door, comprising a U-shaped slide rail 3 and a roller slider 2, the U-shaped slide rail 3 is installed on the sliding door, and the roller slider 2 is installed on the On the fixed side box; the roller slider 2 is connected with the semicircular mandrel of the U-shaped slide rail 3 through the concentric roller 22 and the eccentric roller 23 to form a set of relative motion rolling pairs; the concentric roller 22 and the eccentric roller 23 are radially They are on the same straight line and are distributed in a triangular shape in the axial direction, each of which plays the role of load bearing and guiding. The vertical position of the eccentric roller 23 can be adjusted to re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com