Corrosion-resistant pneumatic spray head and manufacture method thereof

A gas spray head and corrosion-resistant technology, applied in gaseous chemical plating, superimposed layer plating, coating, etc., can solve the problem that ceramic particles cannot reach places that cannot be seen and can be coated to shorten the service life , line of sight effect and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

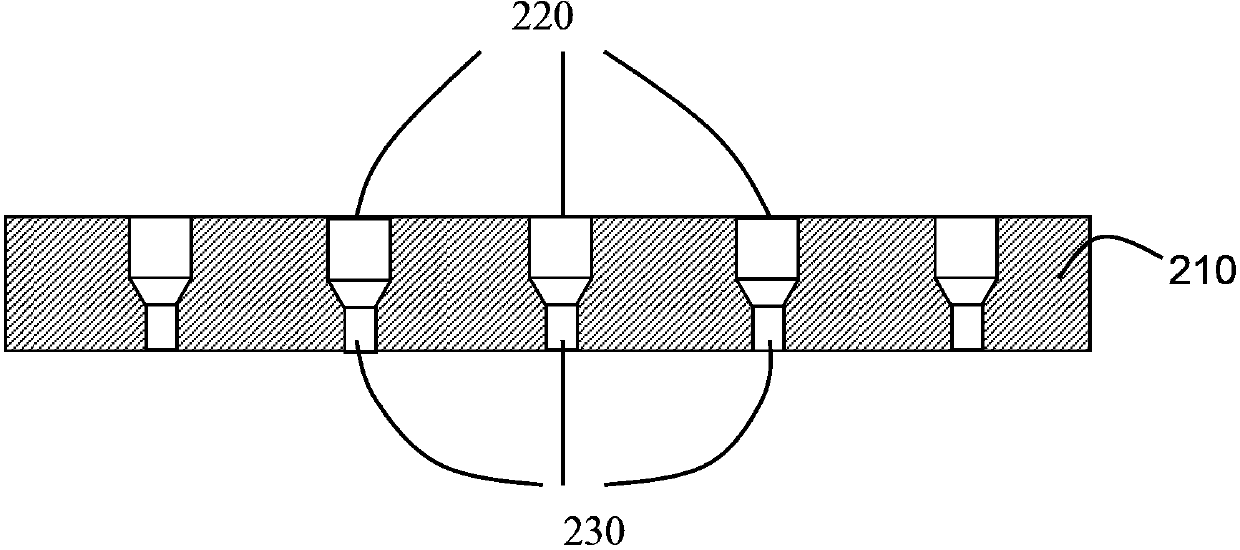

[0023] The specific embodiments of the present invention will be described below with reference to the accompanying drawings, and a gas shower head and its manufacturing method are provided, which can improve the anti-corrosion and particle pollution performance of the gas shower head.

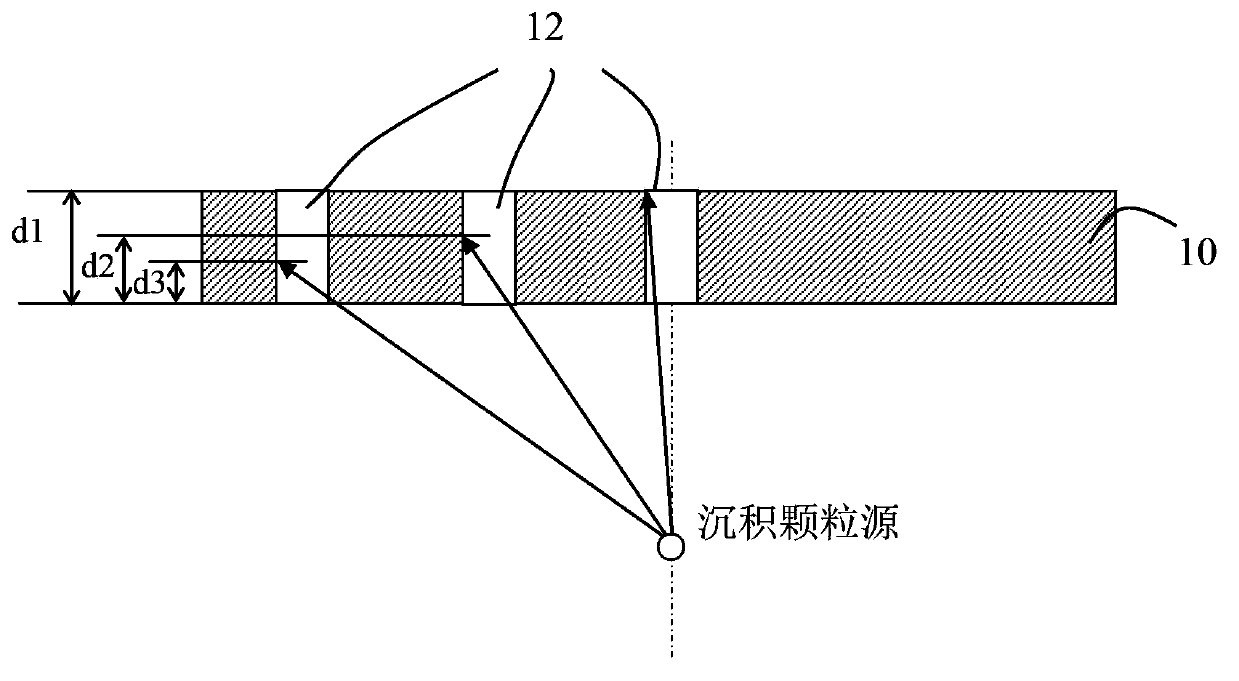

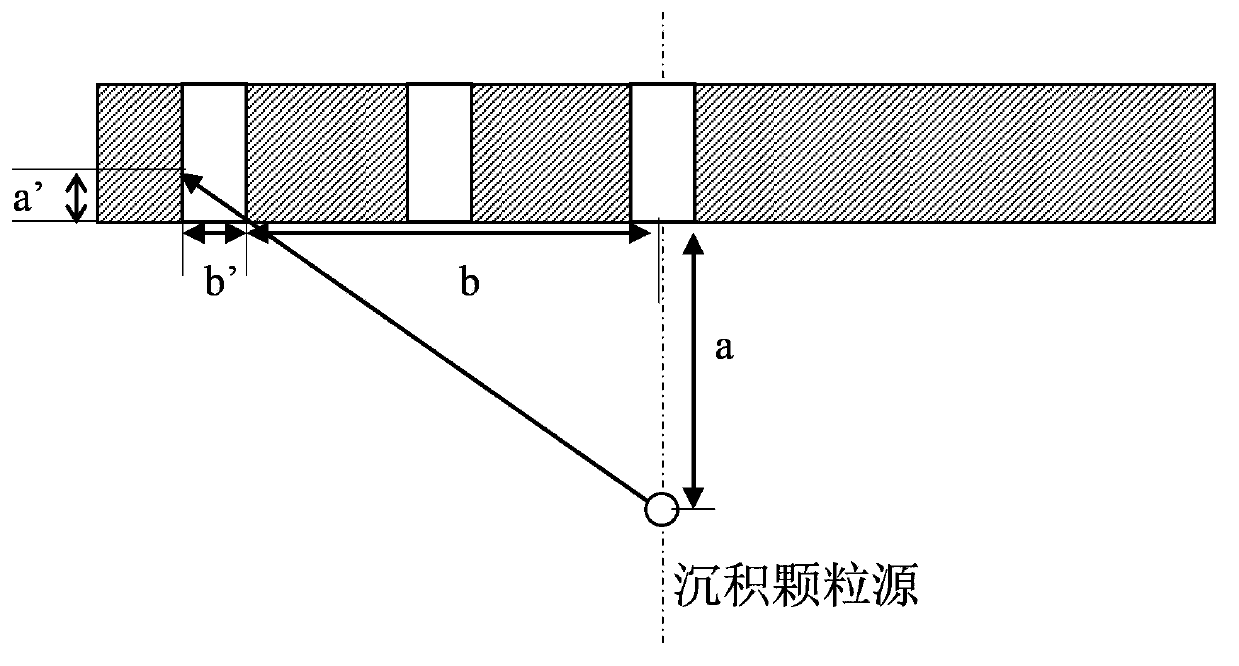

[0024] In the prior art, in order to protect the gas shower head from being eroded by plasma, a plasma erosion-resistant coating, such as a ceramic coating, is usually coated on the surface of the gas shower head main body. Methods for coating ceramic coatings include physical vapor deposition, plasma spraying, etc. Among them, physical vapor deposition is widely used because of its simple operation and low requirements on spraying equipment and environment. When the gas shower head is coated with a corrosion-resistant layer by the physical vapor deposition method, a ceramic deposition source is arranged under the surface of the gas shower head to be coated, and the ceramic in the ceramic depos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com