Chimney deduster

A dust collector and chimney technology, applied in chemical instruments and methods, using liquid separating agents, combined devices, etc., can solve the problems of chimney sewage, affecting the speed of flue gas discharge, aggravating the corrosion of the inner wall of the chimney, and achieving good dust removal effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

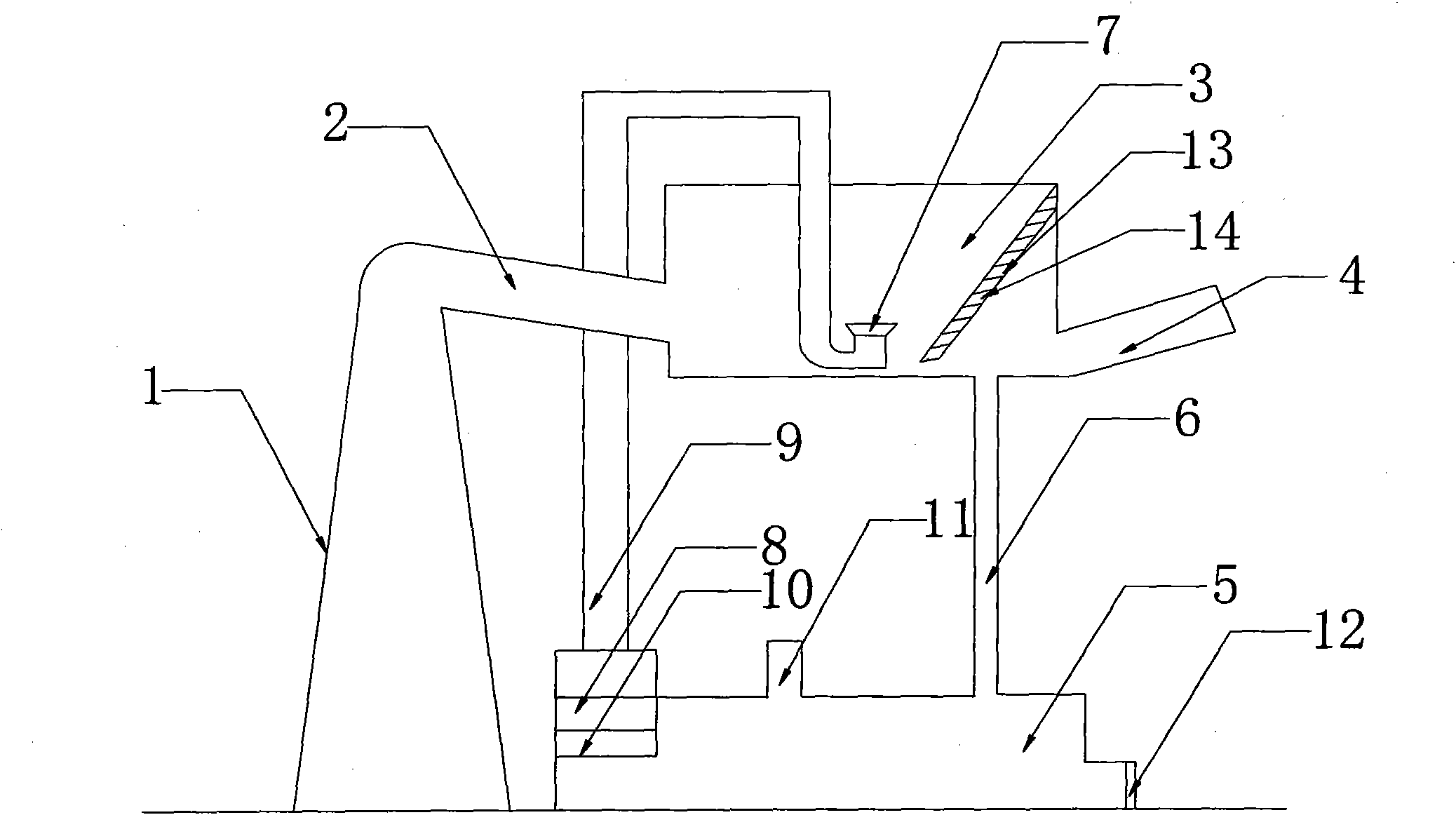

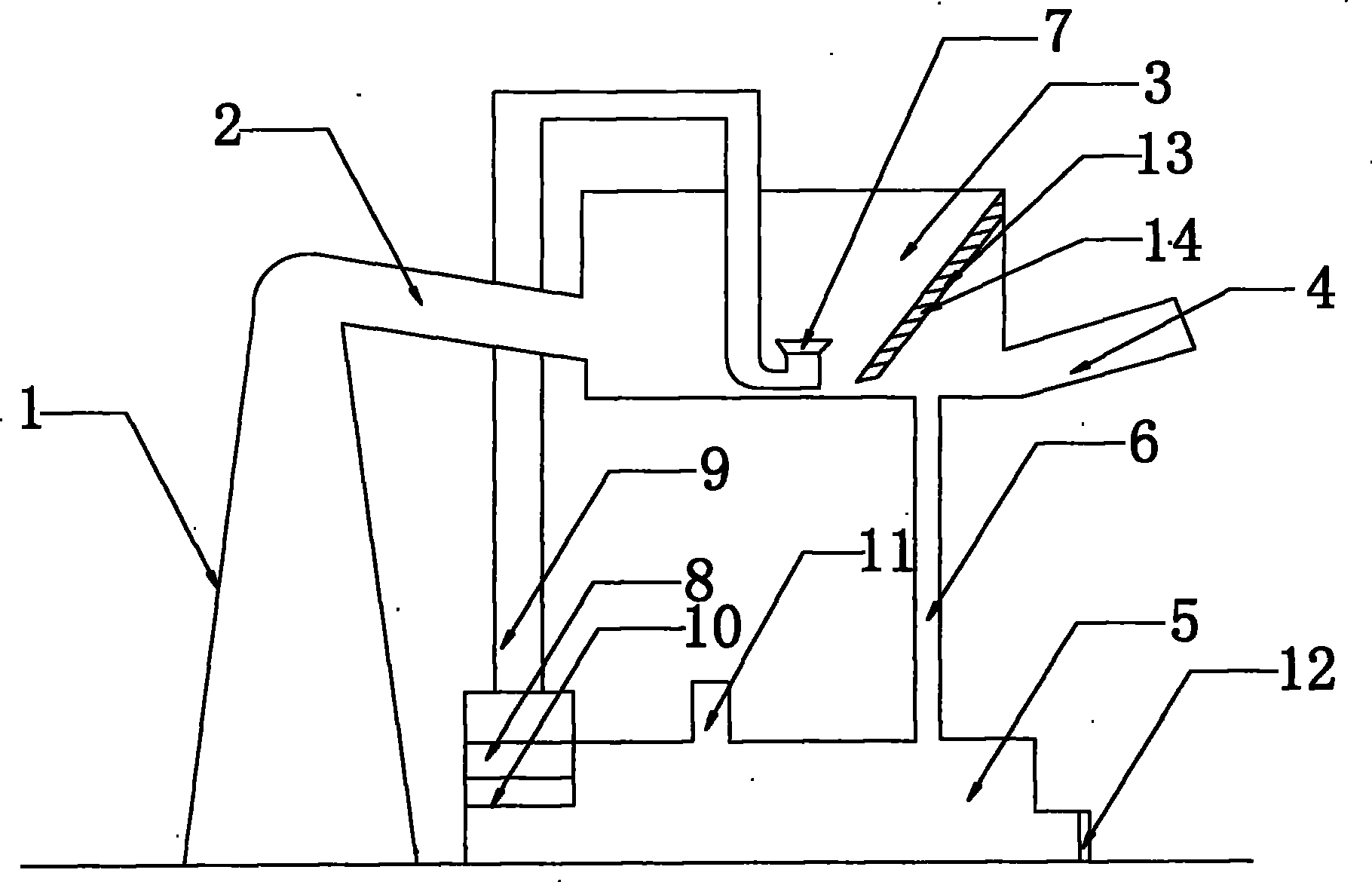

[0011] Such as figure 1 Shown, a kind of chimney dust catcher comprises the flue delivery channel 2 that is communicated with chimney 1 outlet, and the outlet of this flue delivery channel 2 is connected with dust removal chamber 3, and this dust removal chamber 3 is provided with smoke outlet 4, and in dust removal chamber 3 The bottom of the bottom is provided with pool 5, and this pool 5 is connected with dust-removing chamber 3 by water pipe 16, and the outlet of flue delivery 2 is lower than the outlet of chimney 1, is provided with sprayer 7 at the bottom of dust-removing chamber 2, and this sprayer 7 passes water pump 8 and water pipe II 9 are communicated with pool 5, and water pipe II 9 is provided with filter screen 10 at the junction of pool 5, is provided with water inlet 11 at the top of pool 5, in order to facilitate the discharge of sewage in pool 5, set at the bottom of pool 5 There is a slag discharge port 12, and in order to enhance the dust removal effect, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com