A kind of method that urea ammonium nitrate solution carries out turbidity removal and filling simultaneously

A technology of urea ammonium nitrate and solution, which is applied in the directions of transportation and packaging, liquid distribution, conveying or transferring device, packaging, etc., can solve the problems of low production capacity, poor separation effect, high energy consumption, and avoid excessive filter holes. The effect of blocking, intuitive and convenient operation, and large production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

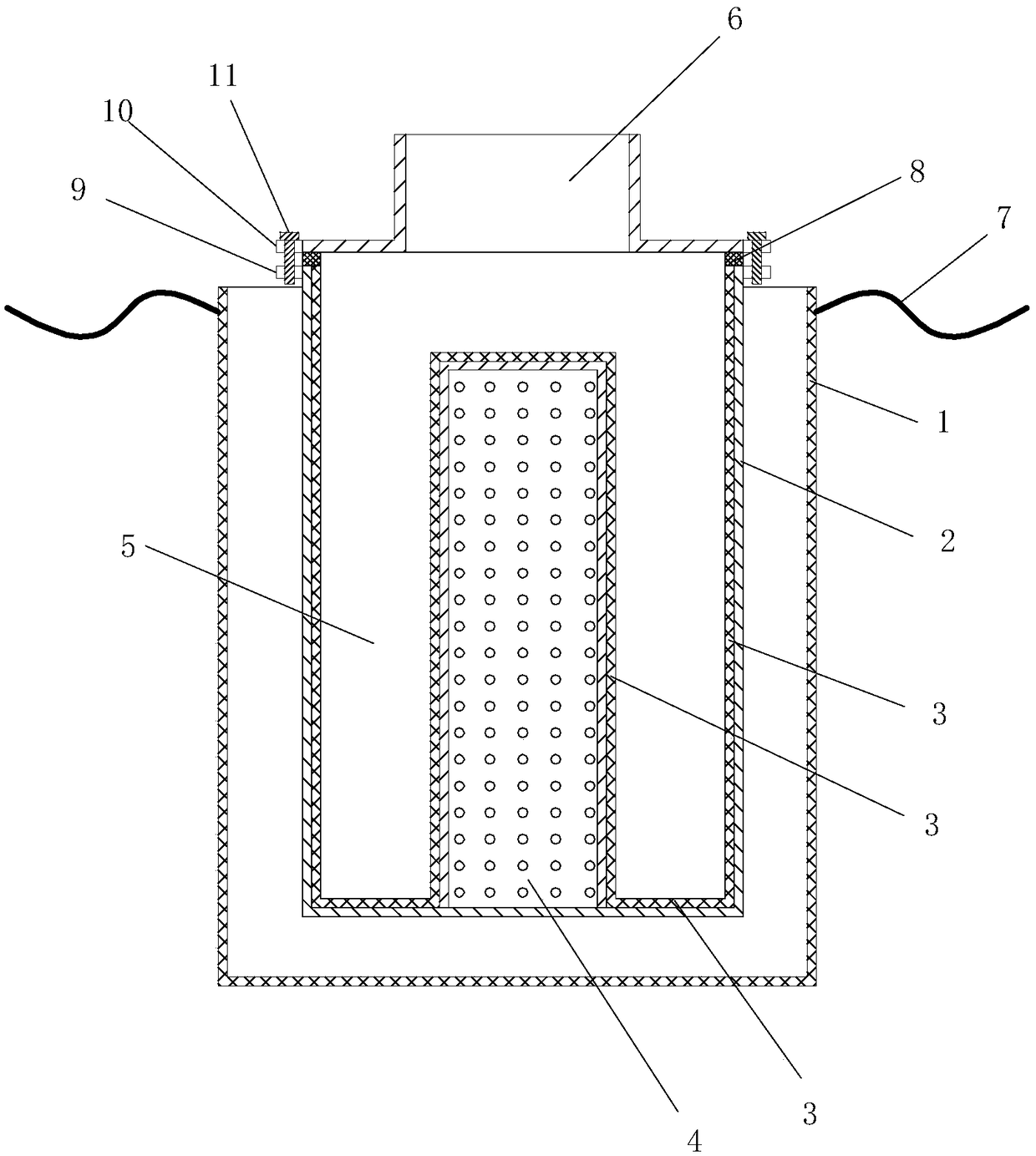

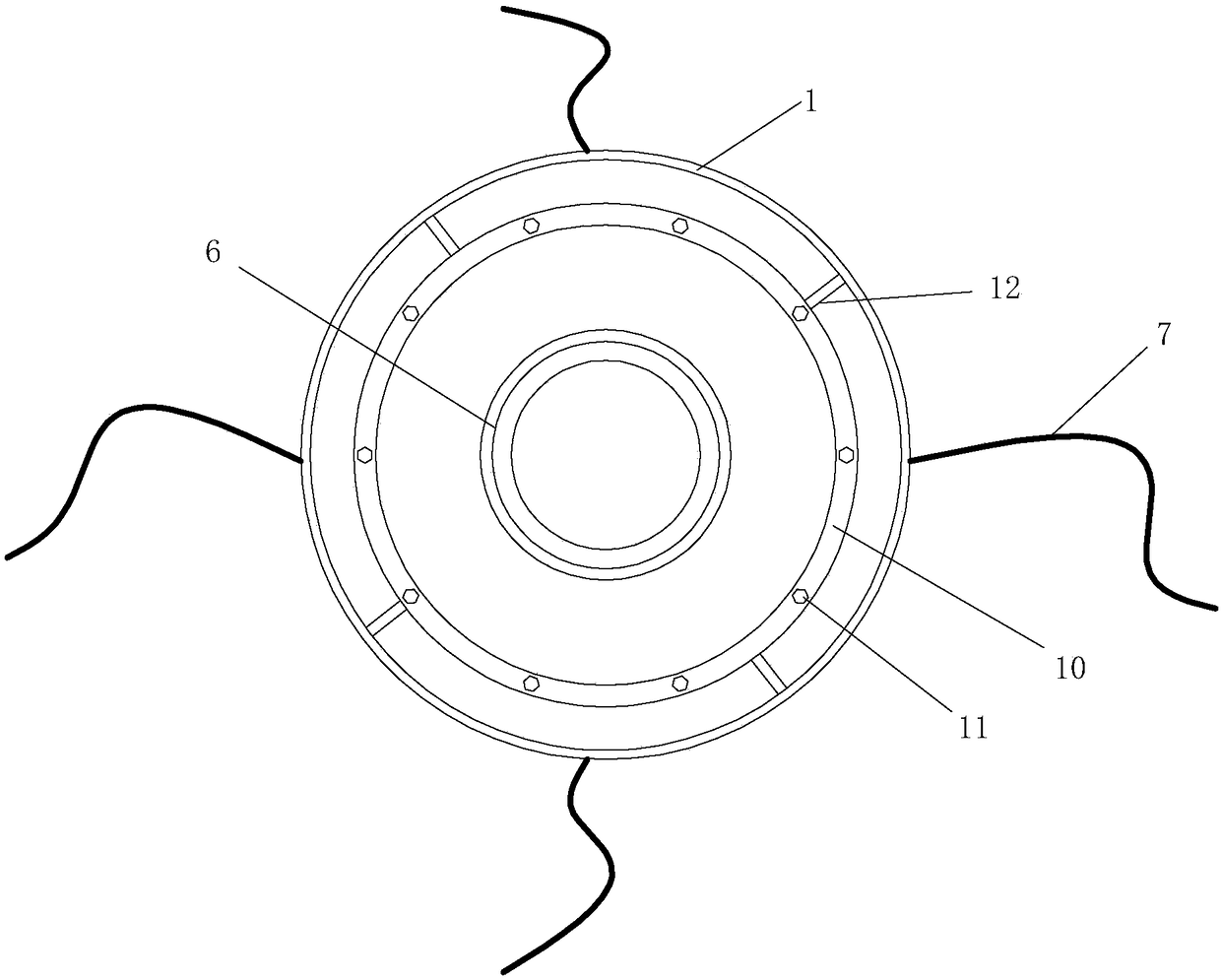

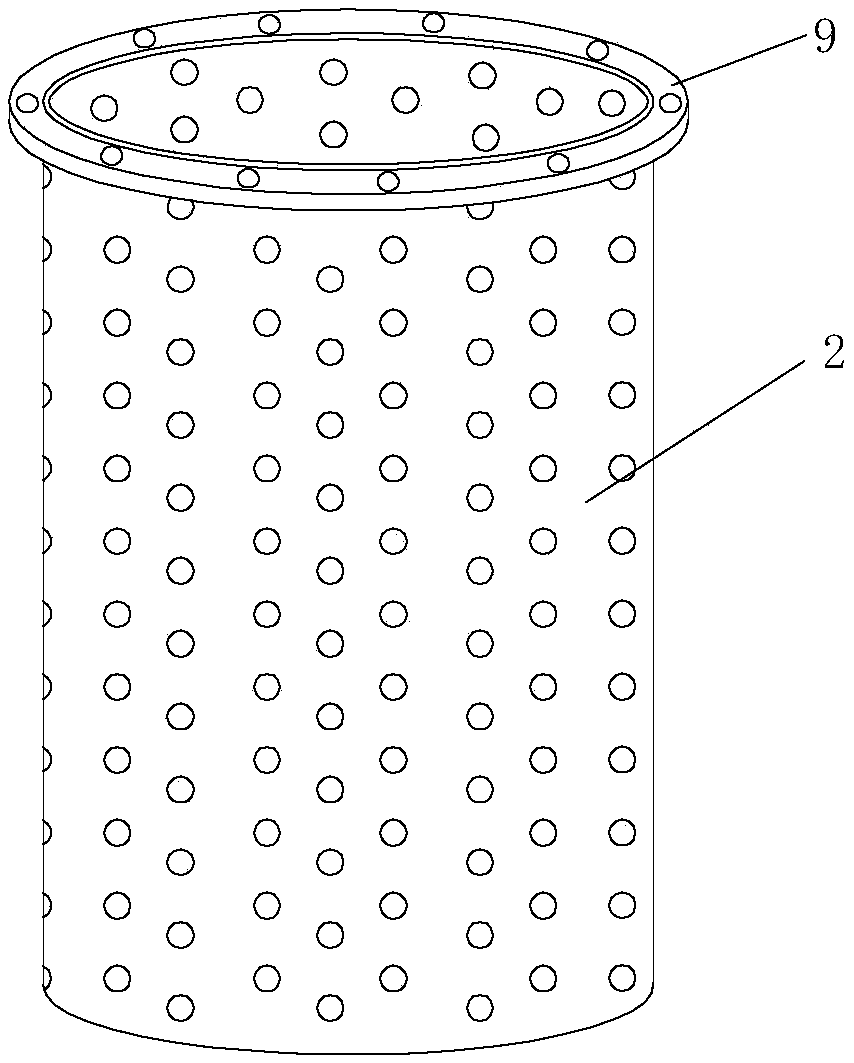

[0034] Example 1: A method for simultaneously removing turbidity and filling of a urea ammonium nitrate solution. The method adopts a urea ammonium nitrate solution filling system. The urea ammonium nitrate solution filling system includes a turbidity removal device 29 and a urea ammonium nitrate solution filling system that is connected sequentially through a pipeline. The storage tank 21, the filter tank 22, the delivery pump 23 and the filling hose 28, that is, the outlet of the storage tank 21 is connected with the inlet of the filter tank 22, the filter tank 22 is provided with a filter screen, and the filter tank 22 can prevent coarse and hard objects such as sand When the pump enters and breaks the impeller, the outlet of the filter tank 22 is connected with the inlet of the conveying pump 23, and the outlet of the conveying pump 23 is connected with the filling hose 28.

[0035] The turbidity removal device 29 includes a first turbidity removal component and a second turbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com