Liquid distributor assembly and air conditioner comprising same

A liquid separator and air conditioner technology, applied in refrigeration components, refrigeration and liquefaction, fluid circulation arrangement, etc., can solve the problems of poor heating effect, inconsistent proportions, frosting of heat exchangers, etc., and achieve better heating effect , Simple structure, uniform defrosting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

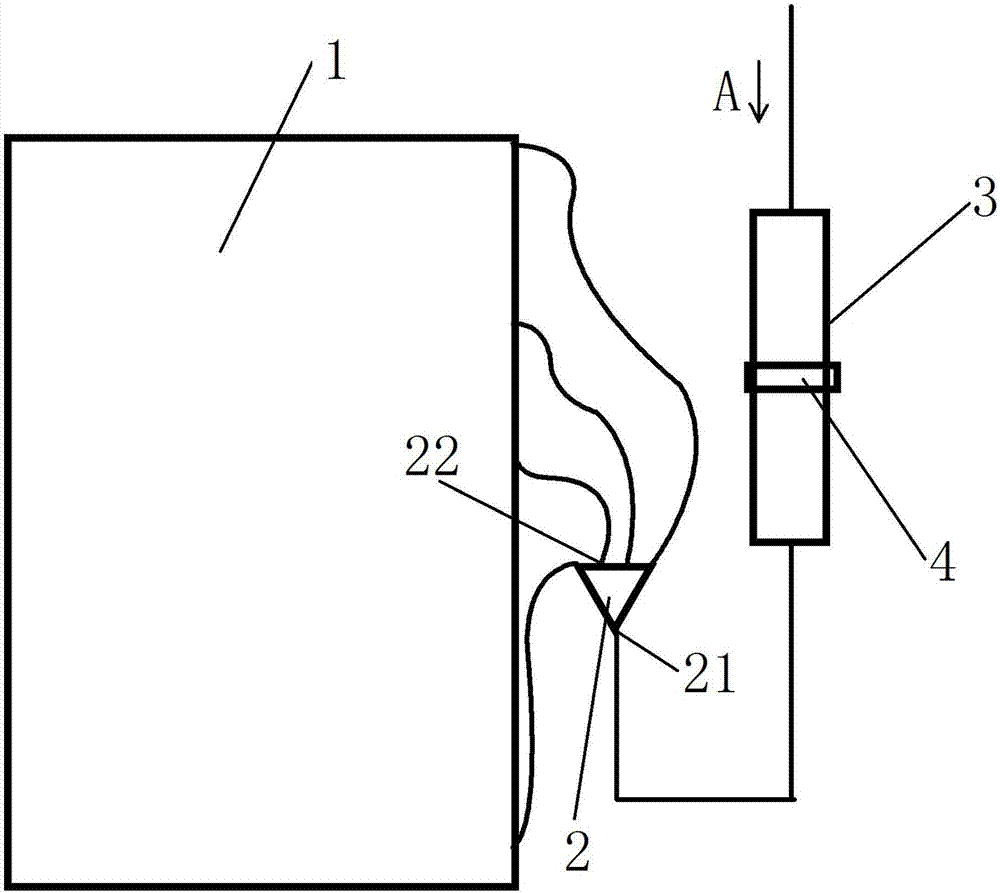

[0037] In this embodiment, on the basis of the above implementation, the gas-liquid separator 3 is provided with a heating device 4, such as figure 1 As shown, the pressure in the gas-liquid separation pipe 30 is increased by the heating device 4 and the temperature of the refrigerant entering the liquid separator 2 is increased to extend the defrosting cycle of the heat exchanger 1 and optimize the heating effect of the unit. The heating device 4 is arranged on the electric heating belt outside the gas-liquid separator 3 . The electric heating belt is arranged in the middle of the gas-liquid separator 3 .

[0038] In this embodiment, the length of the gas-liquid separator 3 is replaced by 0.4 times the height of the heat exchanger 1 . The diameter of the gas-liquid separator 3 is replaced by 4 times of the gas collector. The liquid distribution port 22 in the liquid distribution head 2 is arranged upward and the refrigerant outlet 32 of the gas-liquid separator 3 is highe...

Embodiment 3

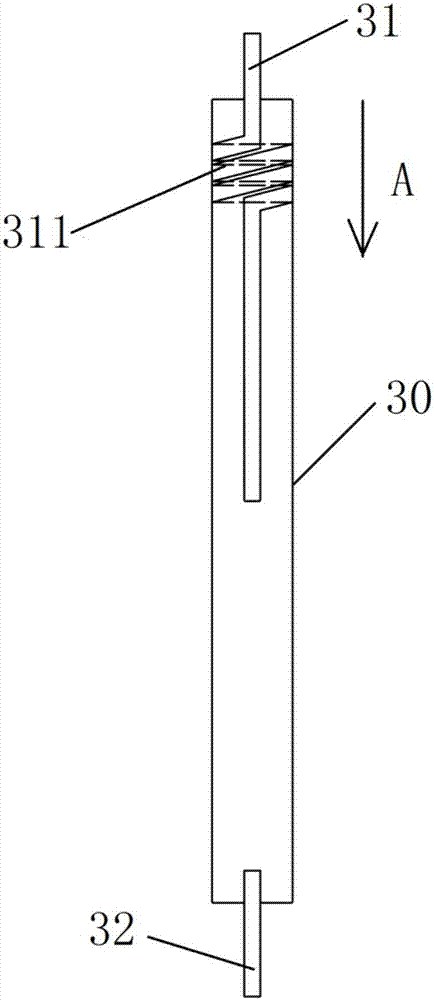

[0040] Further, on the basis of the above implementation 1 or 2 in this embodiment, the gas-liquid separator 3 in the liquid separator assembly is vertically arranged, and the refrigerant outlet 32 of the gas-liquid separator 3 is higher than the Bottom of heat exchanger 1. In this embodiment, the length of the gas-liquid separator 3 is replaced by 0.6 times the height of the heat exchanger 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com