Liquid reinforcing agent

A technology of reinforcing agent and liquid is applied in the field of reinforcing agent, which can solve the problems of low mud suspension and flexural difference in production of green body, and achieve the effects of simple preparation method, improved flexural strength, and improved suspension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

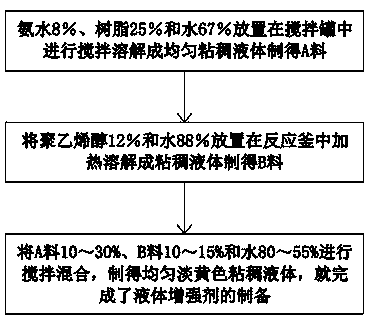

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0018] Please refer to figure 1 ,in, figure 1 It is a flowchart of the preparation method of the liquid enhancer provided by the present invention. The liquid enhancer includes raw materials in the following mass ratio: 10-30% of material A, 10-15% of material B and 80-55% of water. The material A is prepared from the following raw materials: 8% ammonia water, 25% resin and water 67%; the B material is prepared from the following raw materials: polyvinyl alcohol 12% and water 88%;

[0019] Its preparation method comprises the following steps:

[0020] S1: 8% ammonia water, 25% resin and 67% water are placed in a stirring tank for stirring and dissolving into a uniform viscous liquid to prepare material A;

[0021] S2: heat and dissolve 12% polyvinyl alcohol and 88% water in a reactor to form a viscous liquid to obtain material B;

[0022] S3: Stir ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com