Chimney dust collector

A dust collector and chimney technology, applied in lighting and heating equipment, etc., can solve the problems of chimney sewage, affect the speed of flue gas discharge, and aggravate the corrosion of the inner wall of the chimney, and achieve a good effect of dust removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

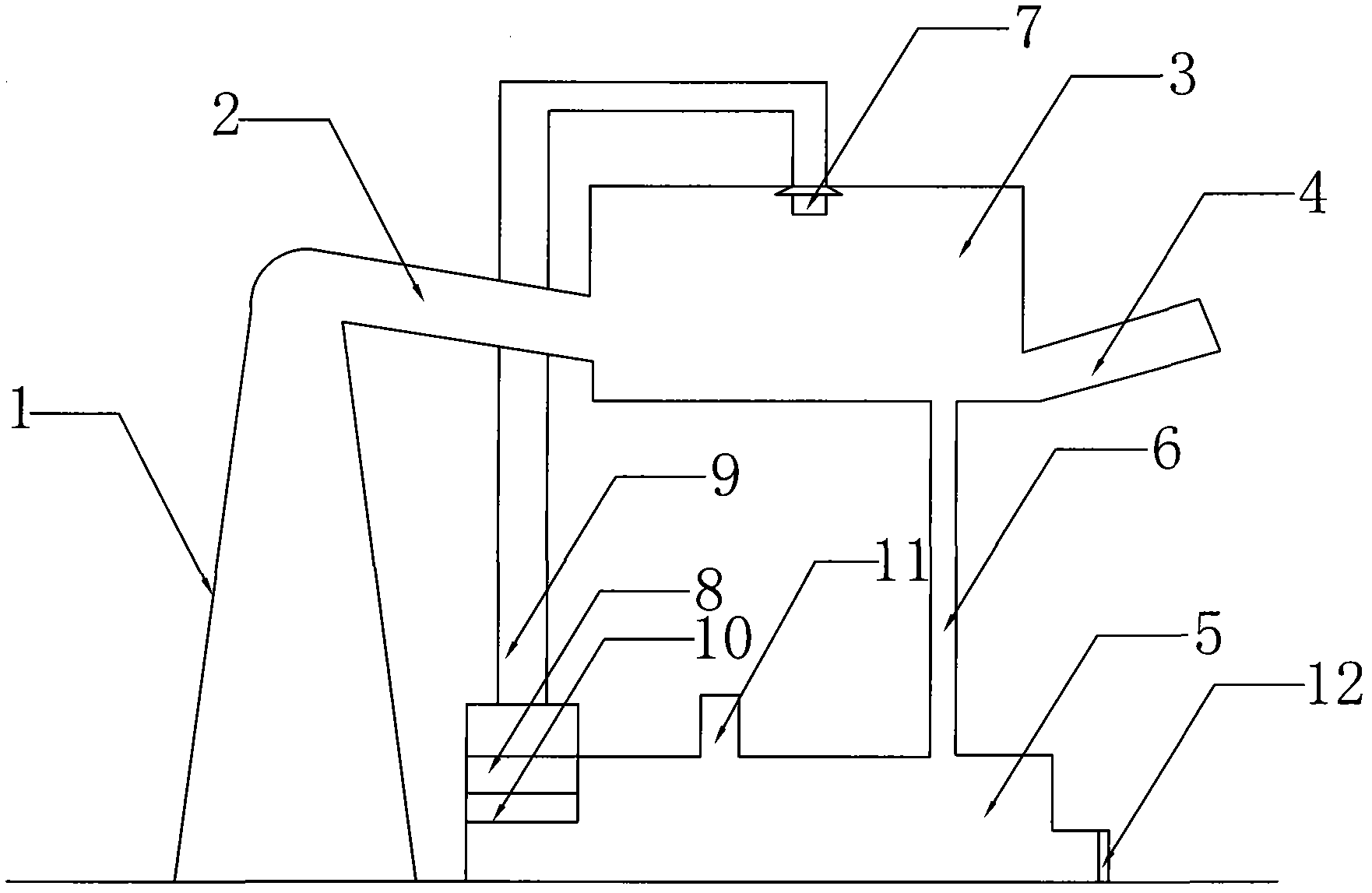

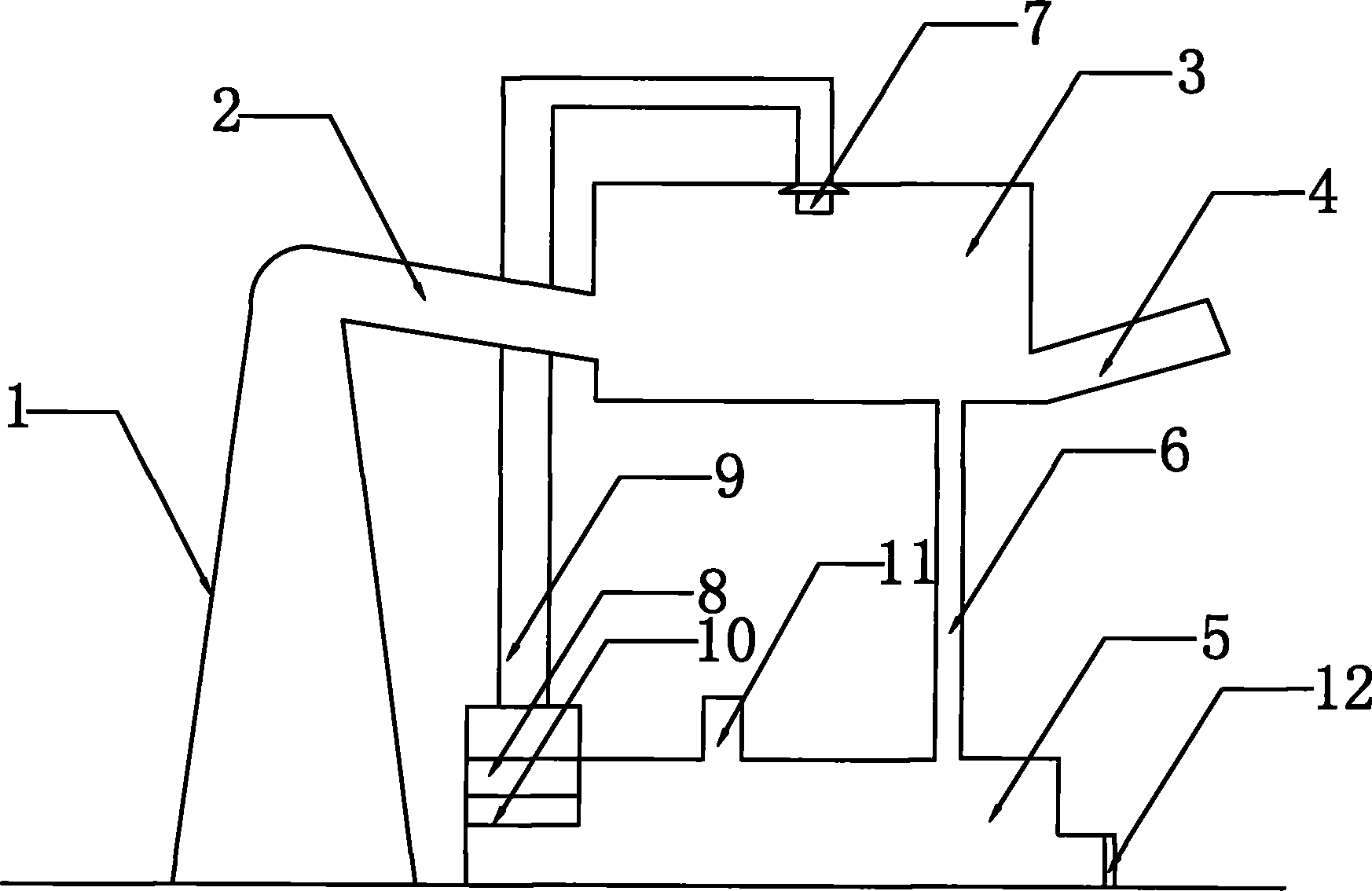

[0011] like figure 1 As shown, a chimney dust collector includes a flue duct 2 that is communicated with the outlet of the chimney 1, and the outlet of the flue duct 2 is connected with a dust chamber 3, and the dust chamber 3 is provided with a smoke outlet 4, and in the dust chamber 3 There is a pool 5 at the bottom of the filter, which is connected to the dust chamber 3 through the water pipe I6, the outlet of the flue 2 is lower than the outlet of the chimney 1, and a sprayer 7 is arranged on the top of the dust chamber 2, and the sprayer 7 is passed through the water pump 8 And the water pipe II9 is communicated with the pool 5, a filter screen 10 is provided at the connection between the water pipe II9 and the pool 5, and a water inlet 11 is provided at the top of the pool 5. In order to facilitate the discharge of sewage in the pool 5, a slag discharge is provided at the bottom of the pool mouth 12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com