Cracking furnace COT thermocouple and mounting method thereof

A cracking furnace and thermocouple technology, applied in the direction of using electric devices, thermometers and measuring devices using electric/magnetic elements that are directly sensitive to heat, can solve problems such as expansion of protective tubes, short service life, and rising system costs. Achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

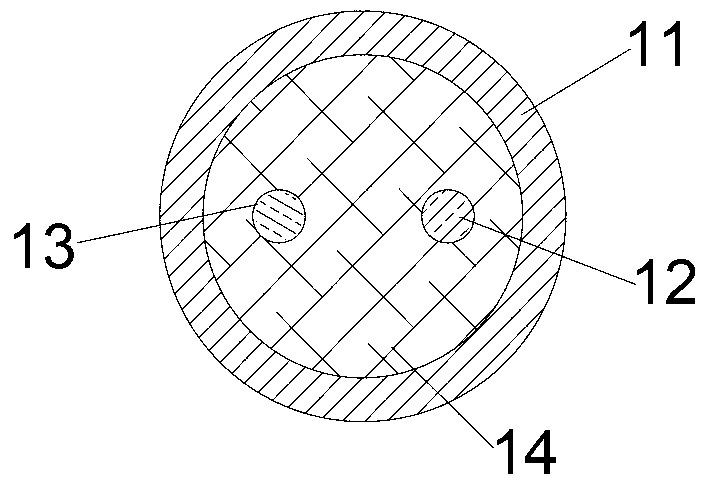

[0048] figure 1 It is a cross-sectional schematic diagram of an armored thermocouple in a cracking furnace COT thermocouple according to an embodiment of the present invention.

[0049] like figure 1 As shown, positive (+) and negative (-) thermal electrodes are assembled in the protective tube 11 of the armored thermocouple, wherein the material of the positive thermal electrode thermal electrode wire 12 is nickel chromium, and the material of the negative thermal electrode thermal electrode wire 13 is For nickel silicon. In the protection tube 11 and between the positive thermal electrode thermal electrode wire 12 and the negative thermal electrode thermal electrode wire 13, insulating materials such as magnesium oxide or aluminum oxide are filled as the insulating medium 14, so that the positive thermal electrode thermal electrode wire 12 and the ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com