Insulated oil pipe and preparation method thereof

A technology for oil pipes and insulation layers, applied in the field of pipelines, can solve problems such as waste of resources and collection and transportation costs, increased oil flow resistance, increased oil friction resistance, etc., to achieve reduced friction, long service life, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

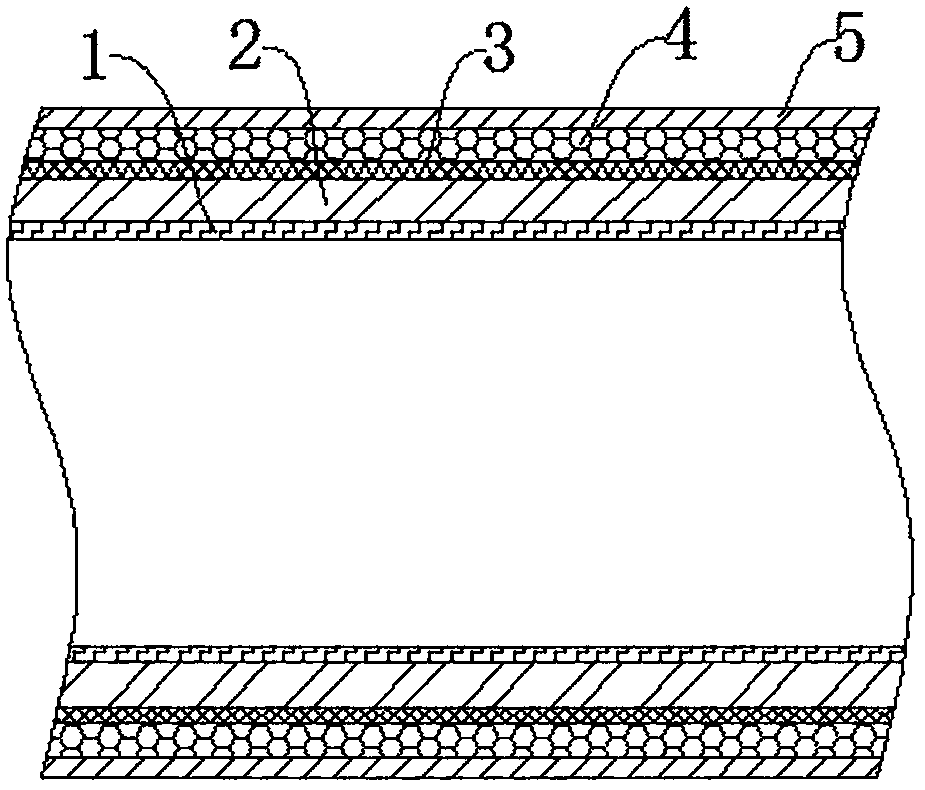

[0024] In this embodiment, the preparation method of the thermal insulation oil pipe includes the following steps:

[0025] Step 1: Treat the surface of the oil pipe base 2, clean the outer surface and inner surface of the oil pipe base 2 until it is free of dust, oil, water and other attachments, and then set aside;

[0026] Step 2: Apply clay evenly on the inner surface of the tubing base 2, and then sinter;

[0027] Step 3: Prepare the material of the thermal insulation layer 3, and spray the airgel thermal insulation coating or the nano-modified polyurethane composite thermal insulation coating by molding or the other nano thermal insulation coatings by bonding The process is applied on the outer surface of the tubing matrix 2;

[0028] Step 4: After the thermal insulation layer 3 in the above step 3 is dried, wrap or socket the material of the protective layer 4 on the outer surface of the thermal insulation layer 3;

[0029] Step 5: Wrap the material of the anti-corros...

Embodiment 1

[0031] In this embodiment, in the step 3, the airgel thermal insulation coating is sprayed on the outer surface of the tubing base 2 as the thickness of the thermal insulation layer 3 is 3 mm, and the airgel thermal insulation coating The material used for the layer is mixed and stirred from the following ingredients, including: nano airgel 10%, lithium titanate whisker 8%, inorganic fiber powder 15%, polysulfone resin 10%, 901 airgel special adhesive 10% agent, 5% glass powder, 2% silane coupling agent, 5% nano-boron carbide, and the rest is deionized water.

[0032] In this embodiment, in the step 4, when the protective layer 4 is made of glass fiber reinforced plastic composite glass fiber protective layer 4, the winding thickness is 1.5 mm.

[0033] In this embodiment, in the step 5, the anti-corrosion layer 5 is sprayed on the outside of the protective layer 4 with a strong anti-corrosion rubber resin, with a thickness of 0.2mm.

[0034] The properties of the obtained th...

Embodiment 2

[0040] In this embodiment, in the step 3, the material used in the nano-modified polyurethane composite thermal insulation coating is mixed and stirred from the following components, including: polyurethane rigid foam combined polyether 30%, polymerized MDI, 30%, nano airgel 30%, carbon nanotube 5%, polysilazane 2%, polynonylidene urea 3%, the thickness of the nano-modified polyurethane composite thermal insulation coating is 5mm.

[0041] In the present embodiment, in the step 4, the protective layer 4 is sleeved on the surface of the thermal insulation layer 3 with a rubber heat-shrinkable tube sleeve, and shrunk by hot air at 150° C., with a thickness of 1 mm.

[0042] In this embodiment, in the step 5, the anti-corrosion layer 5 is sprayed with polyurea paint, with a thickness of 1mm;

[0043] The properties of the obtained thermal insulation oil pipe are as follows:

[0044] The apparent thermal conductivity is: 0.021w / m.k;

[0045] Maximum temperature resistance: 170°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com