Method for manufacturing a large-outside-diameter equal-diameter titanium tee joint

A production method and a technology with large outer diameter, which are applied in the field of metal material processing to achieve the effects of beautiful appearance, smooth and smooth inner side walls, and time saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Attached below Figure 1-4 An embodiment of the present invention is described.

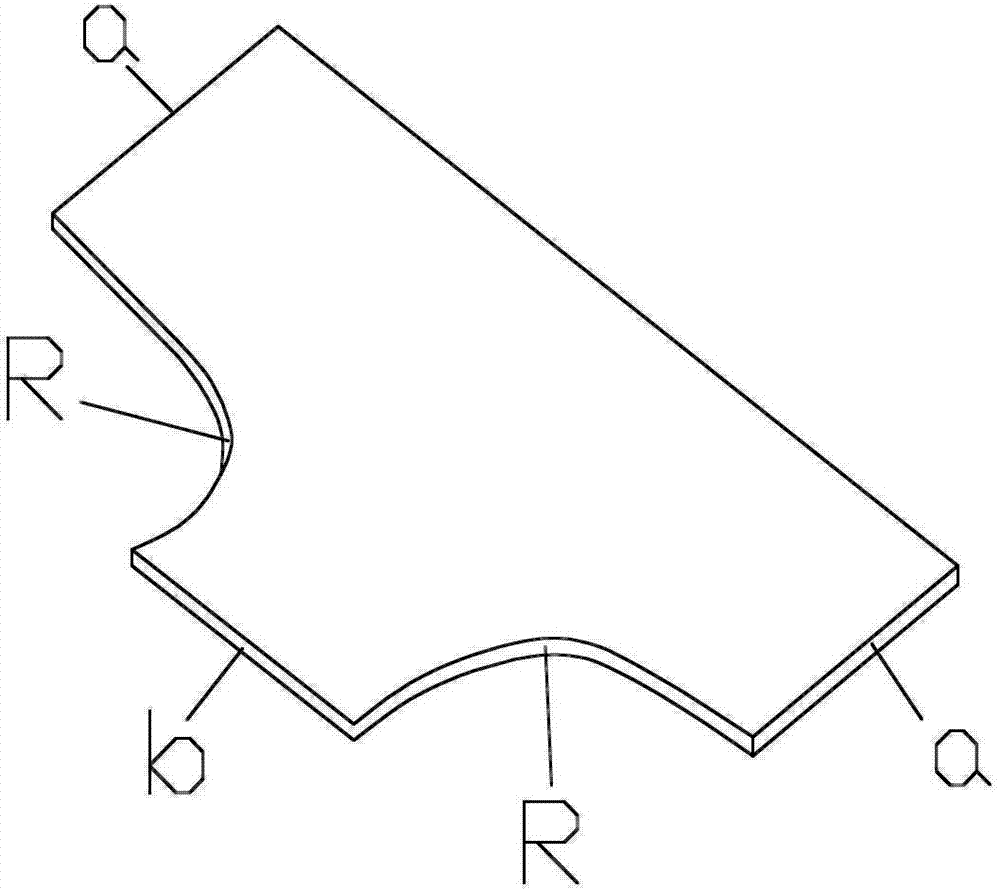

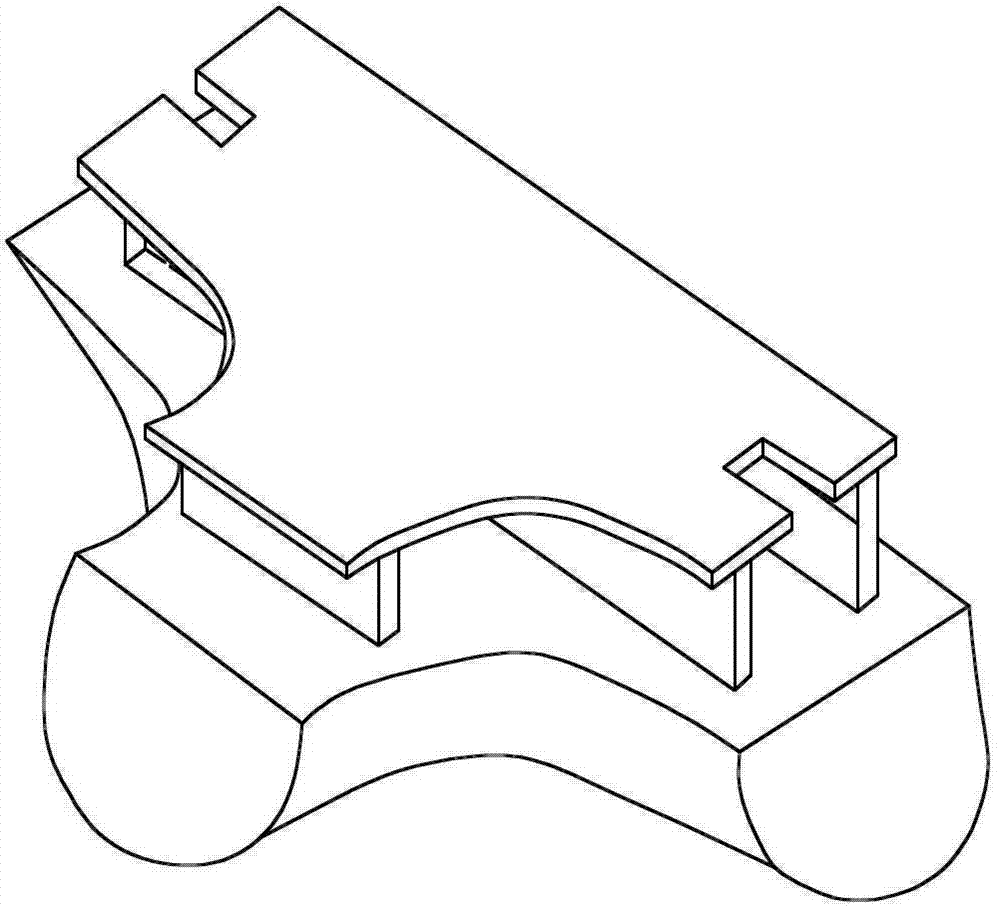

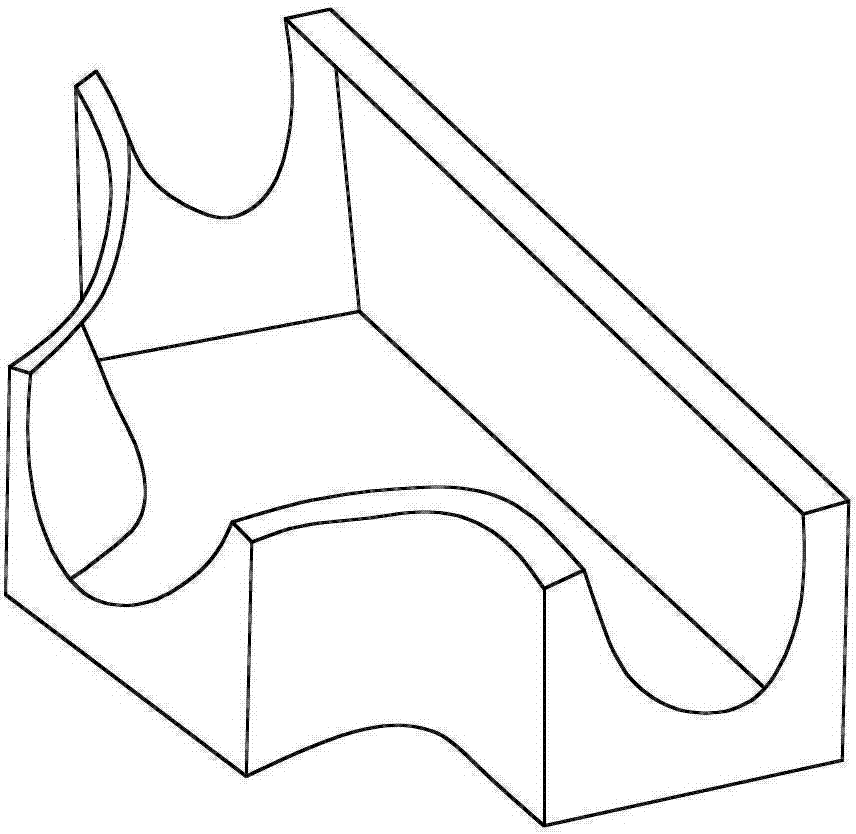

[0019] Implement each mold structure that the present invention needs as Figure 1-4 as shown, figure 1 Cutting sample: According to the plane expansion diagram of the tee, the technician divides the tee equally and draws the blanking sample. In the figure, a is the plan view of half of the main pipe of the tee, b is the plan view of half of the branch pipe, and R is the arc angle of the main pipe and the branch pipe; figure 2 Upper mold: Tee mold designed according to the specific dimensions of the tee; image 3 Bottom mold: According to the specific dimensions of the tee, the tee mold is designed, and the upper mold is included in it to match; Figure 4 Formed wool: the finished material, after heating, is extruded into half a tee wool with upper and lower molds.

[0020] Using the above mold, follow the steps below to make a titanium tee:

[0021] (1) Cutting: First, according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com