Technological cylinder cover for machining cylinder holes of engine cylinder body and machining method therefor

A technology for engine cylinders and cylinder heads, which is applied in metal processing equipment, manufacturing tools, drilling/drilling equipment, etc., can solve the problems of shortened engine life, reduced sealing performance, uncontrollable wear, etc., and achieves less lubricating oil consumption, The inner wall is smooth and the effect of reducing sliding frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

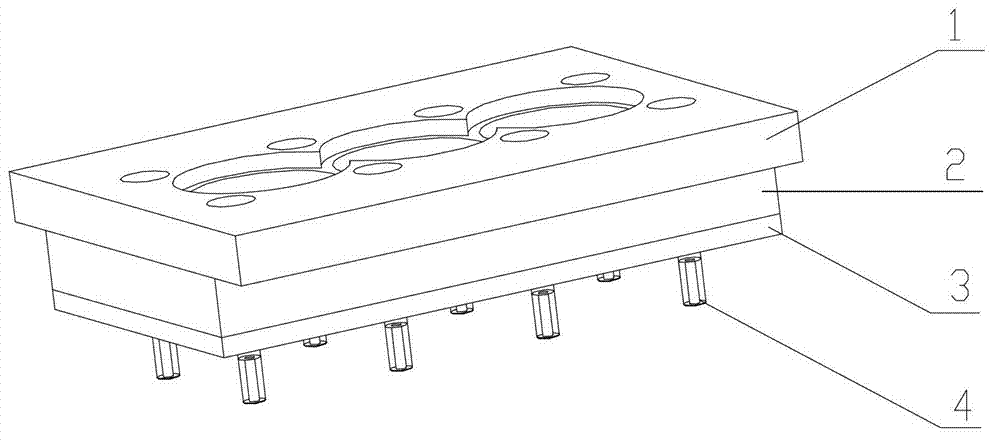

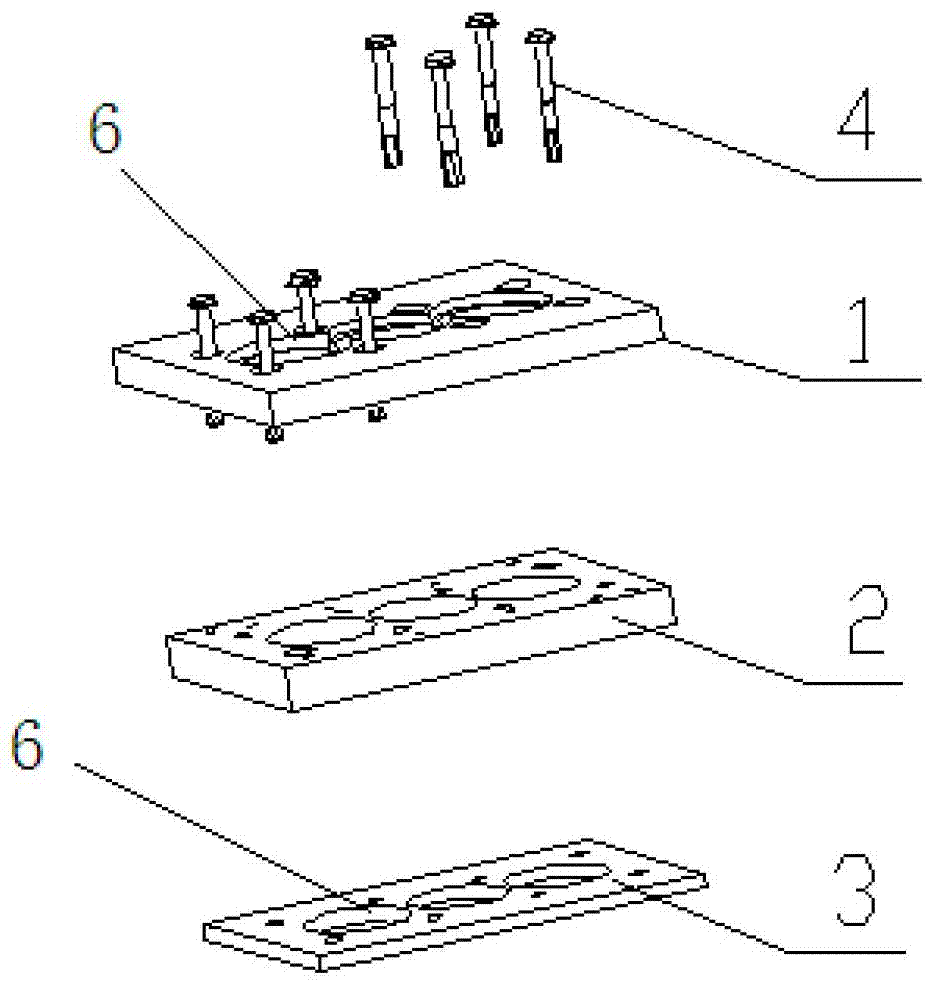

[0018] Further illustrate structure of the present invention below in conjunction with accompanying drawing:

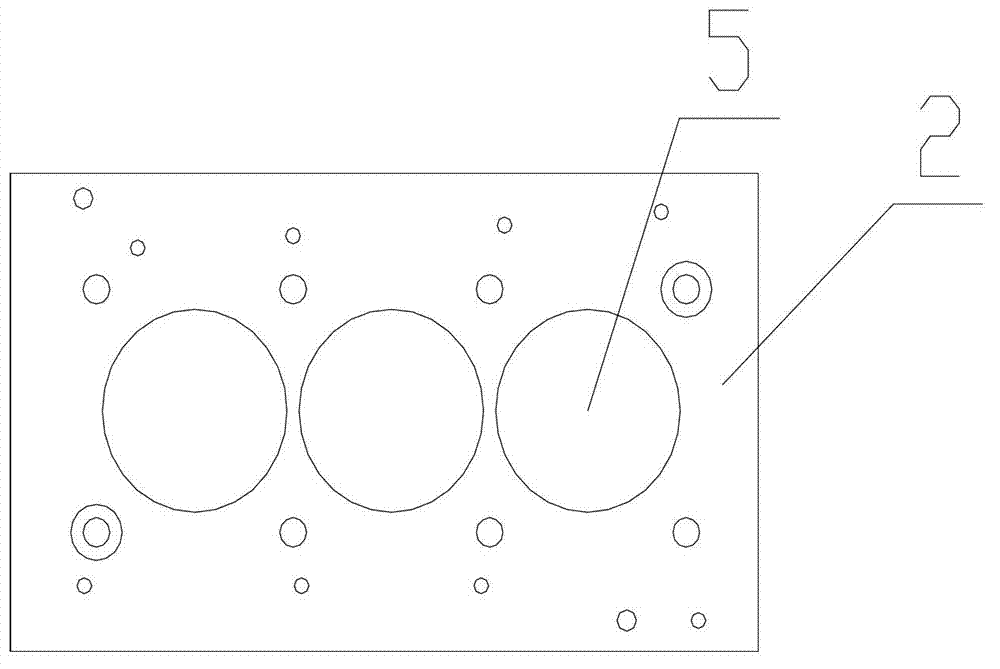

[0019] see figure 1 , the process cylinder head is formed by bolting the upper layer 1 of the process cylinder head, the middle layer 2 of the process cylinder head and the bottom layer 3 of the process cylinder head. The middle layer 2 of the process cylinder head adopts the same aluminum alloy plate as the material of the simulated cylinder head, and there is a hole 5 having the same diameter as the cylinder hole of the processed cylinder body on it. The upper layer 1 of the process cylinder head and the bottom layer 3 of the process cylinder head are made of steel plates, and they are provided with process through holes 6 at positions corresponding to the holes on the middle layer of the process cylinder cover.

[0020] When processing the engine cylinder bore, use bolts 4 to combine the upper layer 1 of the process cylinder head, the middle layer 2 of the process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com