Production process and production line for continuous stainless steel coil

A stainless steel plate and production process technology, applied in the field of heat exchange equipment, can solve the problems of increased liquid film thermal resistance, complex process steps, and reduced heat exchange efficiency, and achieve the effects of easy cold processing, bright and uniform color, and good ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

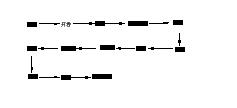

[0023] like Figure 4 The continuous stainless steel coiled pipe production line shown includes pipe production equipment and pipe bending production equipment. Frame (guiding device 3), molding machine 5. The aforementioned devices are dynamically connected by stainless steel belts in sequence. The unit 11 and the high-speed flying saw (cutting device 12) are dynamically connected in turn by stainless steel pipes; the stainless steel pipes after pipe making enter the bending pipe production equipment through the transmission equipment 13, and the bending pipe production equipment includes a blanking slide 14, a pipe bending platform 15, The digitally controlled pipe bender 16 and the sizing device 17 are dynamically connected in turn to form a pipe bending production line.

Embodiment 2

[0025] Adopt the production line described in embodiment 1 to produce a kind of continuous stainless steel coil pipe, concrete production process comprises pipe making, pipe bending and three steps of cutting (such as figure 1 ), pipe making, pipe bending and cutting adopt continuous online processing, of which

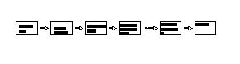

[0026] The first step of tube making: such as figure 2 As shown in the figure, the online continuous pipe making with steel strip as raw material, the pipe production line unit directly extracts the continuous raw material steel strip from the looper for pipe making. Specifically: Uncoiling feeds the looper (feeding speed is usually much higher than the output speed, the maximum can reach 240m / min). Formed by W forming pre-bending machine, after forming, carry out axial welding on-line, and on-line cooling (water-cooled steel pipe reduces the temperature of the pipe body to facilitate polishing and grinding), and on-line grinding and deburring of the welded part of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com