Device and process for preparing struvite crystals from nitrogen and phosphorus in sewage

A struvite, nitrogen and phosphorus technology, which is applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of increased power cost and unfavorable struvite collection, etc. Achieve the effect of small footprint, optimized effluent quality, and good crystallization conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

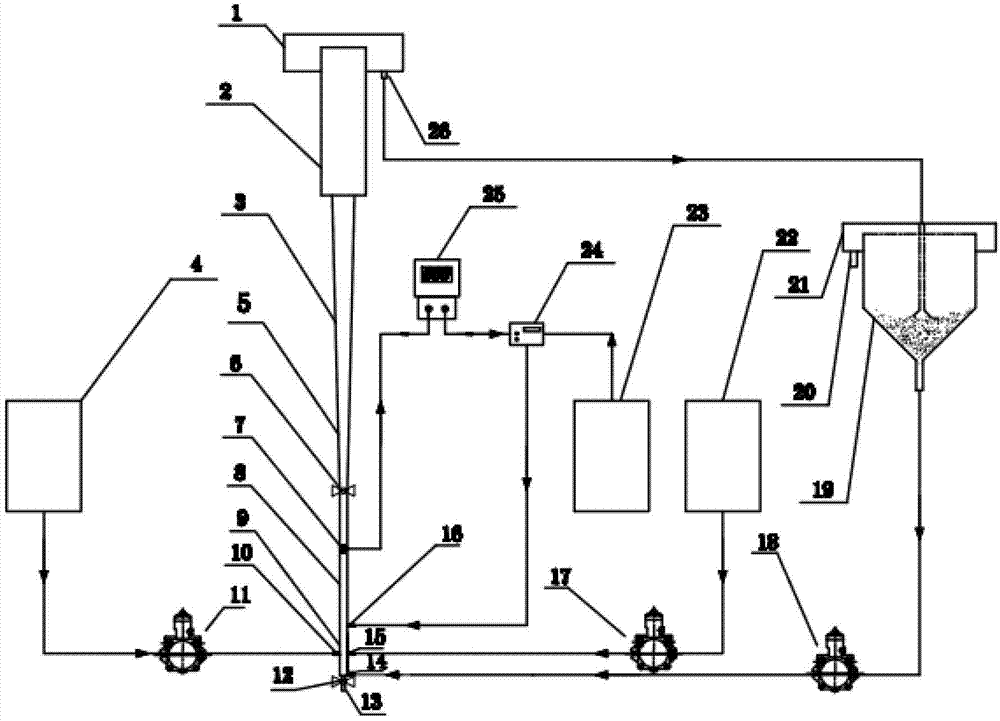

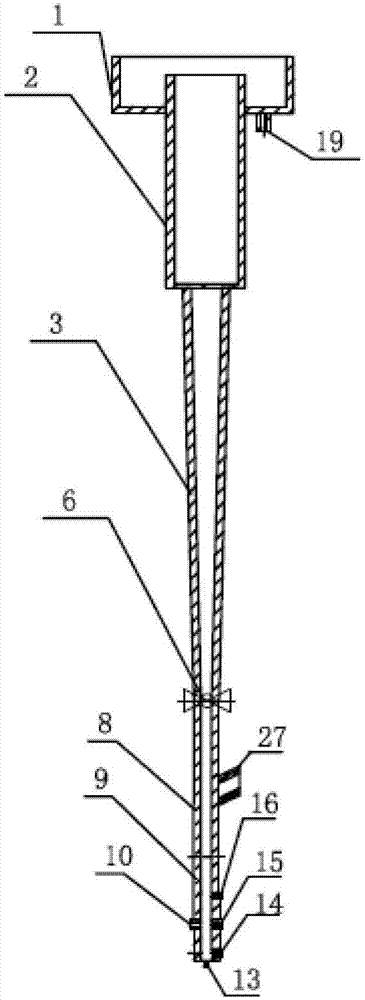

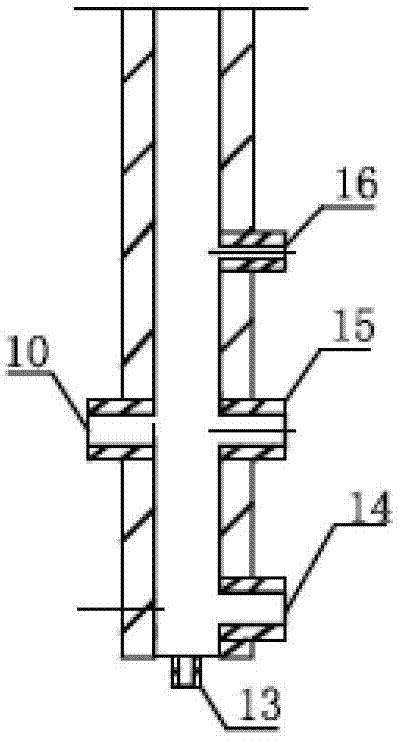

[0031] Please refer to the attached Figure 1-3 . Devices of the invention were constructed.

[0032] Make reactor 5 with transparent plexiglass. The reactor 5 includes a reactor overflow weir 1 , a reactor sedimentation pipe 2 , a reactor growth pipe 3 , a reactor crystal collection pipe 8 and a reactor feed pipe 9 from top to bottom. First make a reactor growth tube 3, the shape of the reactor growth tube 3 is a trumpet-shaped tube with a large top and a small bottom, the diameter of the large end: the diameter of the small end = 3:1; the length of the reactor growth tube 3: small End diameter = 40:1. The top of the big end diameter of the reactor growth tube 3 is welded firmly with the bottom end of the reactor settling tube 2, and the diameter of the reactor settling tube 2 is 2 times of the big end diameter of the reactor crystal growth tube 3, and the diameter of the reactor settling tube 2 There is a reactor overflow weir 1 at the top, and the center of the bottom e...

Embodiment 2

[0036] Simulation of synthetic ammonia wastewater NH 3 -N concentration is 400mg / L, that is, 1 ton of water is pumped into the nitrogenous and phosphorus-containing wastewater tank 22 earlier, ammonium chloride solid 1.528Kg is added in the wastewater tank 22, and then disodium hydrogen phosphate solid 10.228Kg is added in the ammonia nitrogen wastewater, At this time, the NH in the simulated wastewater 3 -N concentration is 400mg / L, PO 4 3- P concentration is 885.7mg / L (maintain NH 3 -N:PO 4 3- P molar ratio 1:1). Configure a magnesium chloride solution containing 685.7 mg / l of magnesium ions (that is, add 5.800 kg of magnesium chloride solid to 1 ton of water), and use the magnesium salt impeller pump 11 to pump the MgCl 2 The solution is pumped into the reactor 5 through the magnesium salt inlet 10 according to the molar ratio of N:P:Mg=1:1:1, and the synthetic ammonia wastewater in the nitrogen-phosphorous wastewater tank 22 is passed through the wastewater inlet 15 ...

Embodiment 3

[0039] The synthetic ammonia wastewater is replaced with glyphosate wet oxidation pretreatment wastewater, and the NH in the glyphosate wet oxidation pretreatment wastewater 3 -N concentration is 1000mg / L. First 1 ton of water is pumped into the nitrogenous and phosphorus-containing wastewater tank 22, and 3.821 kg of ammonium chloride solid and 25.571 kg of disodium hydrogen phosphate solid are respectively added to the nitrogenous and phosphorus-containing wastewater tank 22 to make the NH in the wastewater 3 -N concentration is 1000mg / L, PO 4 3— P concentration is 2214.28mg / L (maintain NH 3 -N:PO 4 3— P molar ratio 1:1), configure the magnesium chloride solution that contains magnesium ion concentration to be 2228.56mg / l, promptly add 18.85kg magnesium chloride solid to 1 ton of water, the NH that pumps into the reactor at this moment 3 -N:PO 4 3— P:Mg 2+ The molar ratio is 1:1:1.25. NaOH solution was used to adjust and maintain pH=6.4±0.1, and other conditions wer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com