Novel making process of cylindrical pin piece of digital transmission connection pin

A technology of cylindrical pins and connecting terminals, which is applied in the field of pin parts manufacturing, can solve the problems of raw material loss and high production costs, and achieve the effects of reducing direct production costs, stable quality, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

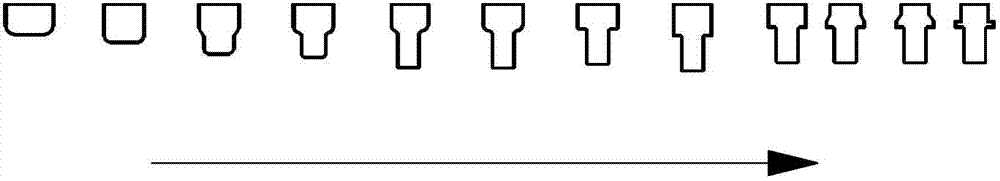

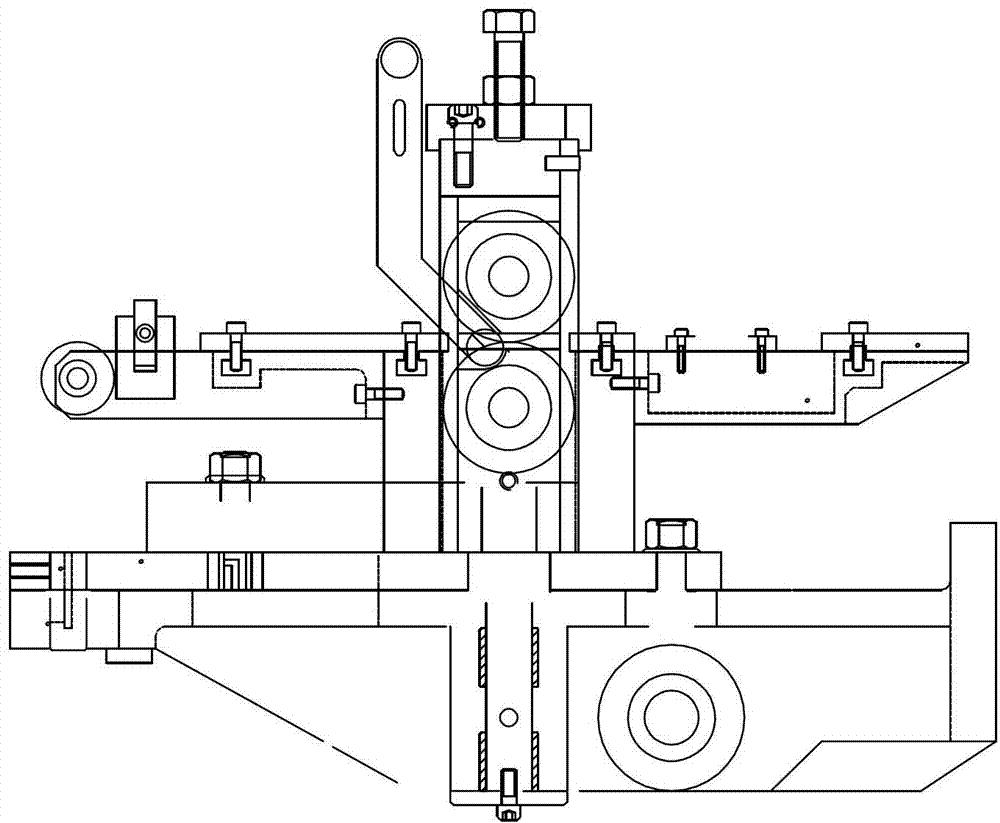

[0017] Such as figure 1 , 2 , 3 and 4, taking as an example the new type of digital transmission connection terminal pin with a diameter of 3.46mm and a length of 16.1mm, it specifically includes the following steps:

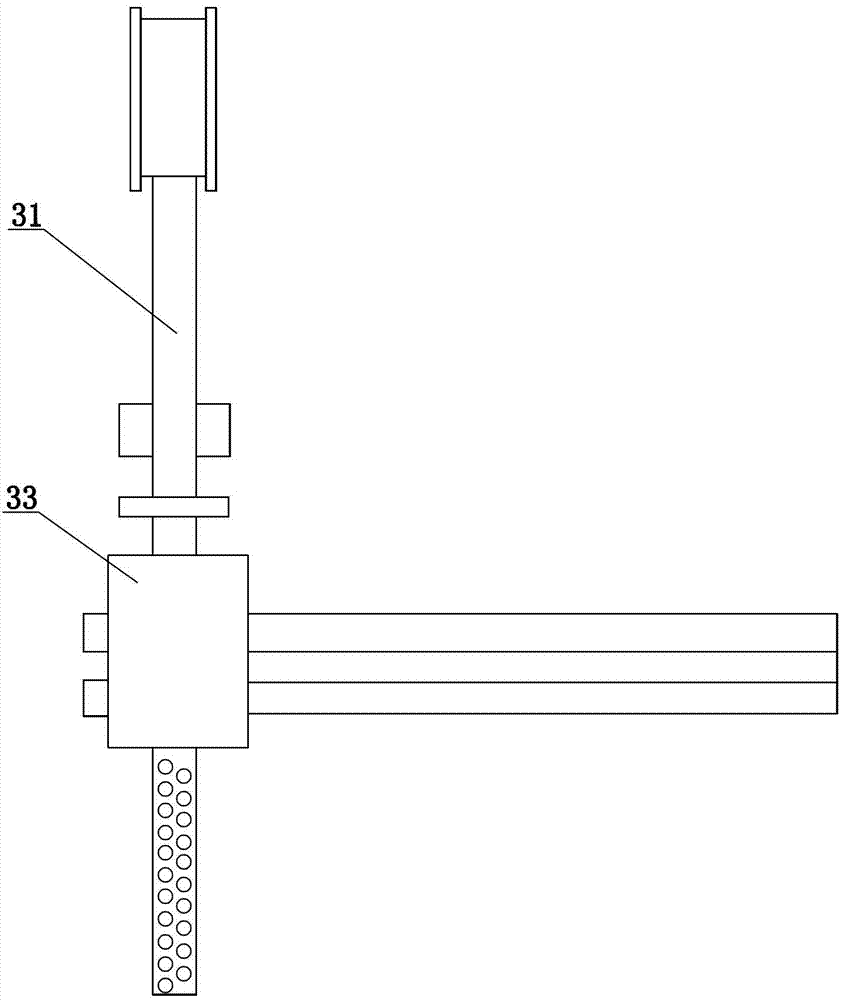

[0018] 1. Material selection: choose a copper strip 31 with a width of 18mm and a thickness of 0.16mm, and place it on a swing feeding device. The feeding device mainly includes a feeding head 1 and a power shaft 14 for providing power. The feeding head 1 has a longitudinal feeding track 2 for shelving the strip material 3, and is characterized in that it also includes a feeding mechanism and a swing mechanism. Described feeding mechanism comprises the upper feeding roller 4 that is positioned at the described feeding track top and is positioned at the lower feeding roller 5 that fits with this upper feeding roller 4 below described feeding track, and described lower feeding roller 5 and drives its rotation The feeding drive shaft 6 is connected to the feed d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com