Preparation method and application of high-stability silicon-based composite material constructed by in-situ fluorination

A silicon-based composite material, silicon-based material technology, applied in the directions of silicon oxide, lithium halide, structural parts, etc., can solve the effect of the stability of the negative electrode material, the effect of which is small, the coating layer of lithium fluoride is uneven, and the negative electrode material is stable. problems such as poor performance, to achieve the effect of low material price, optimization of uniformity and compactness, and improvement of slurry stability and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] (1) 1 g of silicon oxide was dispersed in ethanol solution of 1 g of 10 w% 2-pyrrolidone, and the dispersion was obtained by stirring and ultrasonically dispersing uniform.

[0062] (2) 1.0 g of ammonium fluoride was added to a aqueous solution of 1 g, stirred, and then the solution was added to the dispersion obtained by the solution, and the reaction was stirred for 40 min.

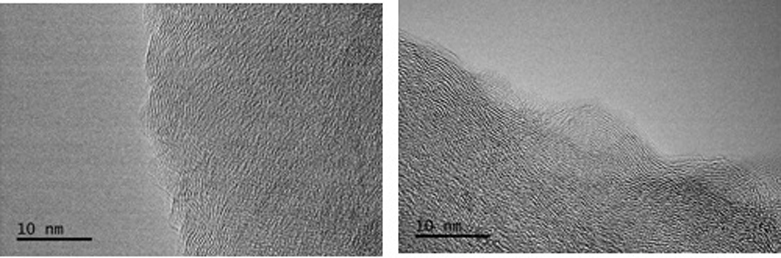

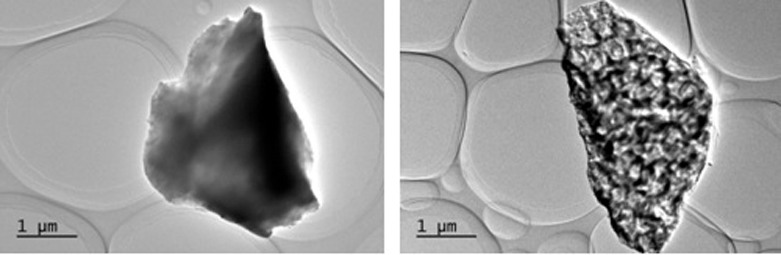

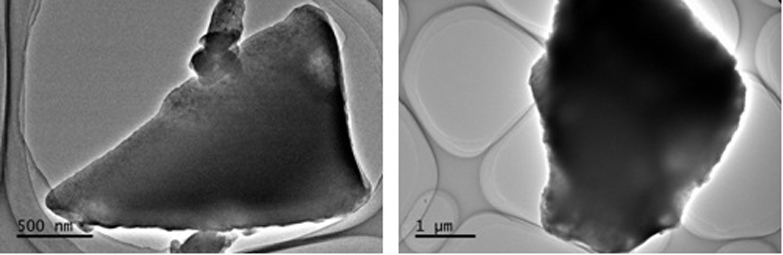

[0063] (3) The product obtained in step (2) first was washed first, and then washed with ethanol, filtered, and 10 h was dried in vacuo at 80 ° C to obtain a silicon-based composite. Fluorine-containing coating forming (Li 2 CO 3 -Lif), according to XRD spectrum, XPS peak results in 1.05% by weight of the lithium fluoride LIF with a silicon base negative electrode material, 0.1% by weight of the silicon-based negative electrode material, lithium fluoride: lithium carbonate mass ratio 10.5.

Embodiment 2

[0065] According to the method of Example 1, the different amount of fluoride in step (2) was changed to 0.6 g, and other steps were as in Example 1. Fluorine-containing coating forming (Li 2 CO 3 -Lif), the quality of lithium fluoride is obtained from the mass of the lithium fluoride in accordance with XPS. The lithium carbonate is about 0.13% by weight of the silicon-based negative electrode material, the lithium fluoride: lithium carbonate mass ratio 6.15.

Embodiment 3

[0067] According to the method of Example 1, the difference is: the amount of fluoride fluoride in step (2) is changed to 1.5 g, and other steps are as in Example 1. Fluorine-containing coating forming (Li 2 CO 3 -Lif), the mass of lithium fluoride accounts for 1.4% by weight of the silicon-based negative electrode material, and lithium carbonate is about 0.07% by weight of the silicon-based negative electrode material, lithium fluoride: lithium carbonate mass ratio 20.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com