Reflective marking belt base material, base material and method for manufacturing reflective marking belt

A technology for marking tapes and substrates, applied in the field of marking objects, can solve the problems of reduced strength, high ground requirements, short service life and unusable use, and achieves the effects of long service life, low cost and strong initial adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

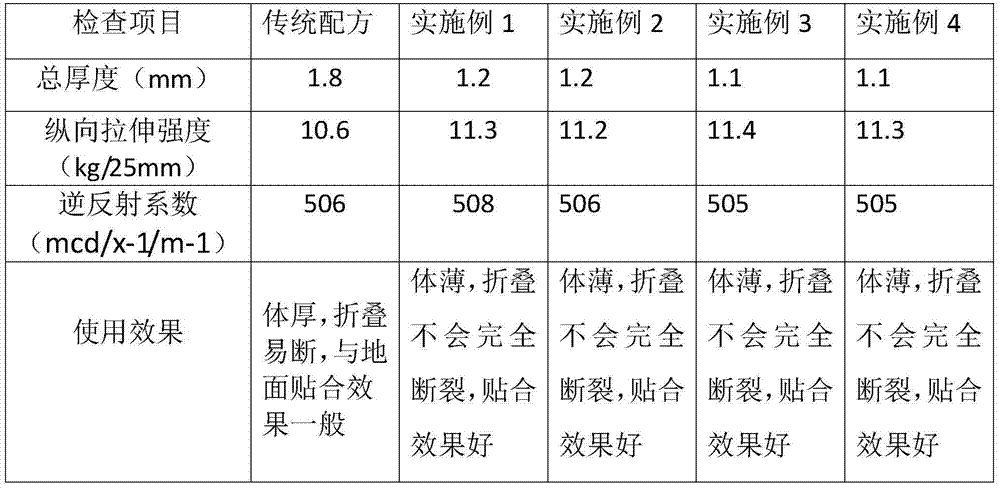

Examples

Embodiment 1

[0030] Components of the base material:

[0031] 8 parts of styrene-butadiene-styrene block copolymer;

[0032] 2 parts of ethylene-vinyl acetate copolymer EVA; 5 parts of quartz sand;

[0033] 7 parts of rosin; 3 parts of petroleum resin; 30 parts of wollastonite powder; 20 parts of calcium carbonate;

[0034] 1 part of yellow pigment; 2 parts of dioctyl ester; 1 part of paraffin; 8 parts of 90 mesh glass beads.

Embodiment 2

[0036] Components of the base material:

[0037] 15 parts of styrene-butadiene-styrene block copolymer;

[0038] 6 parts of ethylene-vinyl acetate copolymer; 10 parts of quartz sand;

[0039] 12 parts of rosin; 6 parts of petroleum resin; 50 parts of wollastonite powder; 40 parts of calcium carbonate;

[0040] 8 parts of white pigment; 5 parts of plasticizer dioctyl ester; 2 parts of paraffin; 15 parts of 100 mesh glass beads.

Embodiment 3

[0042] Components of the base material:

[0043] 10 parts of styrene-butadiene-styrene block copolymer SBS;

[0044] 4 parts of ethylene-vinyl acetate copolymer EVA; 8 parts of quartz sand;

[0045] 10 parts of rosin; 5 parts of petroleum resin; 40 parts of wollastonite powder; 30 parts of calcium carbonate;

[0046] 4 parts of yellow pigment; 3 parts of plasticizer; 2 parts of paraffin; 12 parts of 110-mesh glass microspheres; 1 part of oleic acid amide; 1 part of antioxidant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com