Reinforced ligament tissue engineering scaffold and preparation method for same

A tissue engineering scaffold and enhanced technology, applied in the field of medical devices, can solve the problem of slow decline in the mechanical properties of the scaffold, achieve good biocompatibility, eliminate microporous structure deformation, and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

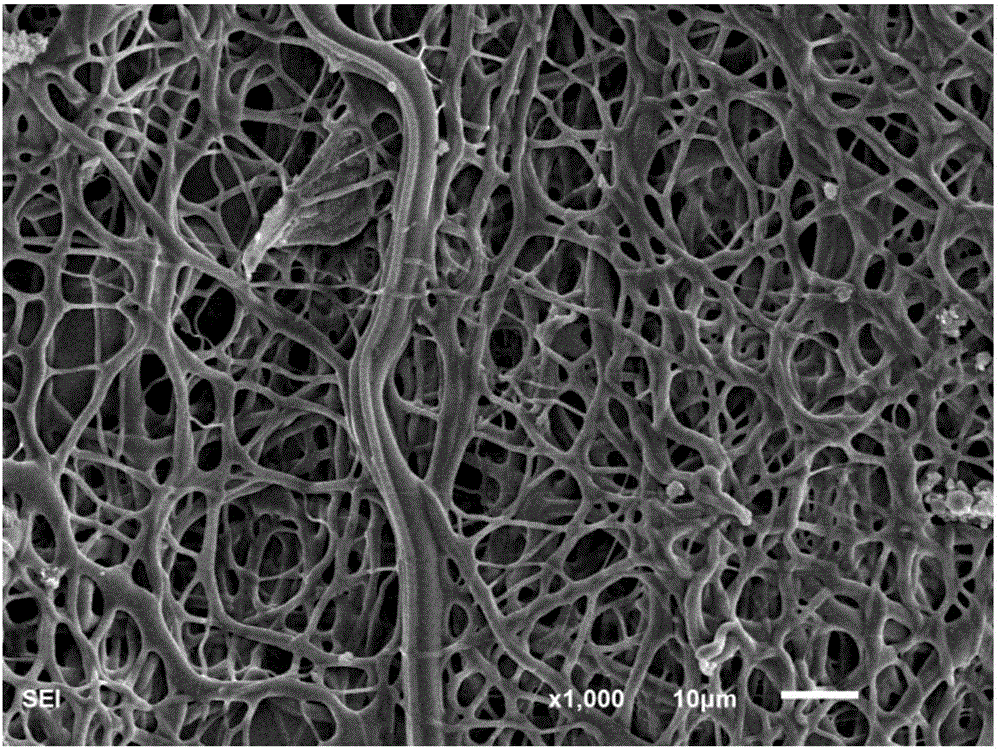

Image

Examples

preparation example Construction

[0026] A method for preparing a reinforced ligament tissue engineering scaffold, comprising preparing a silk fibroin solution or a silk fibroin powder dispersion and a polyvinyl alcohol solution using water as a solvent, and the preparation method is carried out according to the following steps:

[0027]a. Mix the prepared silk fibroin solution or silk fibroin powder dispersion with water as solvent and polyvinyl alcohol solution to obtain a mixed solution, wherein the mass ratio of silk fibroin to polyvinyl alcohol is 1 / 9~1 / 1, the total solute mass concentration of silk fibroin and polyvinyl alcohol is 5wt% to 20wt%, and the mixed solution is sucked into the spinning solution tube for electrospinning;

[0028] b. Preparation of reinforced ligament tissue engineering scaffold by electrospinning

[0029] Using a flat metal strip with a width of 2-15mm and a length of 30-300mm as a collecting plate, place the spinning liquid tube for electrospinning that has absorbed the compos...

Embodiment 1

[0038] a. the silk fibroin aqueous solution with a mass concentration of 5wt% is mixed with a polyvinyl alcohol aqueous solution with a mass concentration of 5wt% to obtain a mixed solution, wherein the mass ratio of silk fibroin to polyvinyl alcohol is 1 / 9, silk fibroin and polyvinyl alcohol The total solute mass concentration of polyvinyl alcohol is 5wt%, and the mixed solution is sucked into the spinning liquid pipe used for electrospinning;

[0039] b. Preparation of reinforced ligament tissue engineering scaffold by electrospinning

[0040] Select a flat metal strip with a width of 2mm and a length of 30mm as the collecting plate, place the spinning solution tube for electrospinning that has absorbed the composite solution in the electrospinning push pump, and push the electrospinning solution at a speed of 0.2ml / hour. The high-voltage power supply outputs a voltage of 5kV. The distance between the nozzle of the spinning liquid pipe and the silk thread collection plate is...

Embodiment 2

[0043] a. the silk fibroin aqueous solution with a mass concentration of 8wt% is mixed with a polyvinyl alcohol aqueous solution with a mass concentration of 8wt% to obtain a mixed solution, wherein the mass ratio of silk fibroin to polyvinyl alcohol is 5 / 5, and silk fibroin and polyvinyl alcohol The total solute mass concentration of polyvinyl alcohol is 10wt%, and the mixed solution is sucked into the spinning liquid pipe used for electrospinning;

[0044] b. Preparation of reinforced ligament tissue engineering scaffold by electrospinning

[0045] Select a flat metal strip with a width of 10mm and a length of 150mm as the collecting plate, place the spinning liquid tube for electrospinning that has absorbed the composite solution in the electrospinning push pump, and the speed of the electrospinning liquid is 2ml / hour. The high-voltage power supply outputs a voltage of 15kV. The distance between the nozzle of the spinning liquid pipe and the silk thread collection plate is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com