Preparation method of carbon nanotube/UiO-66-NH2 nano-composite material

A nano-composite material, uio-66-nh2 technology, applied in chemical instruments and methods, water/sewage treatment, adsorbed water/sewage treatment, etc., can solve the problems of decreased adsorption capacity and surface area, and sharply decreased structural stability, etc. Achieve excellent adsorption efficiency, improve agglomeration and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) A purified mixed solution of multi-walled carbon nanotubes.

[0037] The MWCNTs were immersed in a mixed acid of sulfuric acid and nitric acid with a volume ratio of 3:1, stirred at 80 °C for 24 h, then filtered and washed with deionized water until neutral, and finally dried at 70 °C. The resulting powder is called purified multi-walled carbon nanotubes.

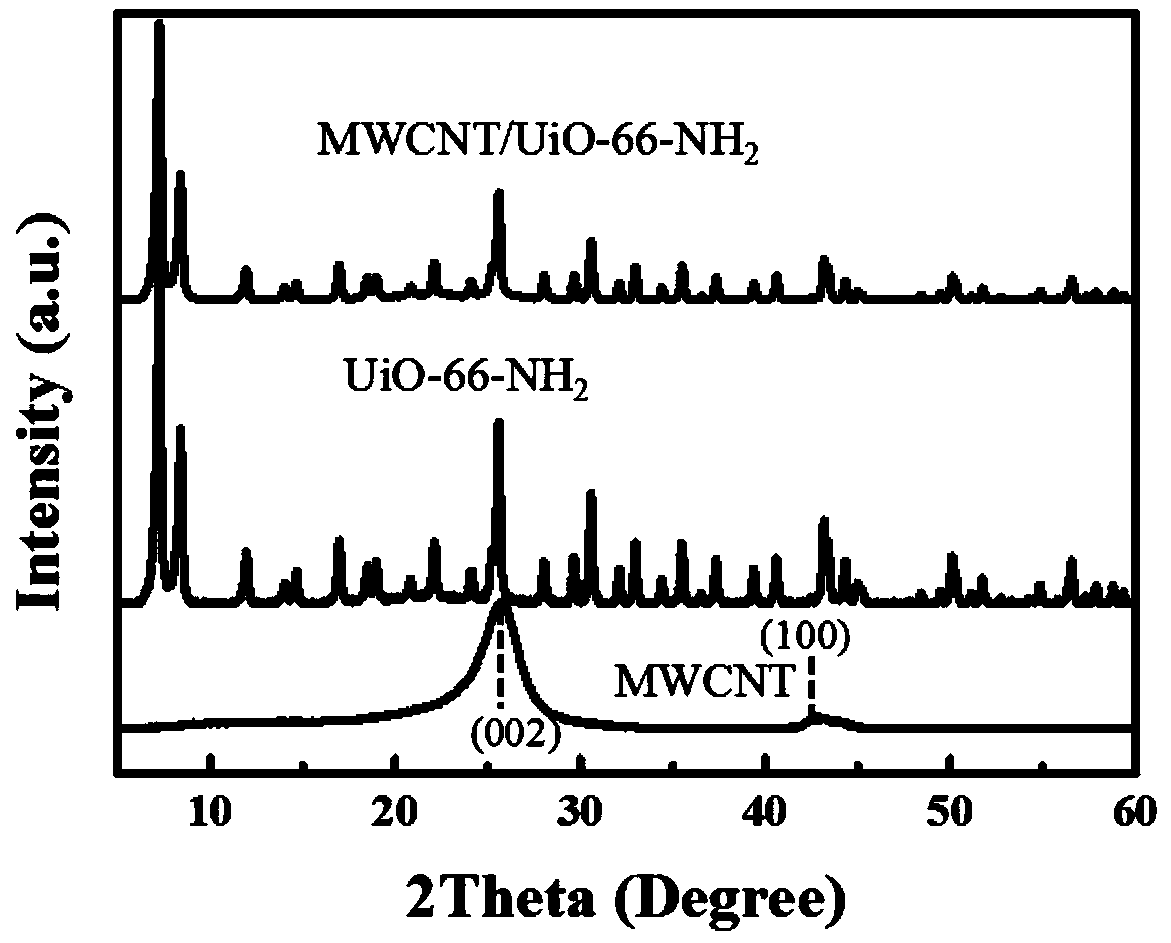

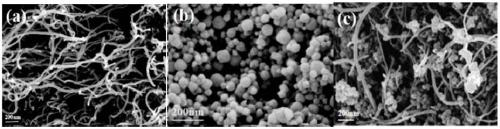

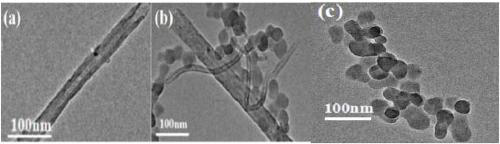

[0038] (2) Preparation of carbon nanotubes / UiO-66-NH by hydrothermal method 2 composite material

[0039] ZrCl 4 and 2-aminoterephthalic acid were added to N,N-dimethylamide, followed by a small amount of acetic acid. Control ZrCl 4 : 2-aminoterephthalic acid: acetic acid: N,N-dimethylamide molar ratio is 1:1:100:500, then add UiO-66-NH to the mixed solution 2 For multi-walled carbon nanotubes that have been functionalized with a material mass of 6 wt%, the mixed solution was ultrasonically treated for 10 minutes, and then stirred overnight. After stirring for 12 hours the mixture was transferred to an auto...

Embodiment 2

[0051] With the control ZrCl in embodiment 1 4 : 2-aminoterephthalic acid: acetic acid: N,N-dimethylamide molar ratio is 1:1:100:500, change to control ZrCl 4 : 2-aminoterephthalic acid: acetic acid: the molar ratio of N,N-dimethylamide is 1:1:100:550, and the others are the same as in Example 1.

Embodiment 3

[0053] With the control ZrCl in embodiment 1 4 : 2-aminoterephthalic acid: acetic acid: N,N-dimethylamide molar ratio is 1:1:100:500, then add UiO-66-NH to the mixed solution 2 The functionalized multi-walled carbon nanotubes with 6wt% of the material quality are changed to control ZrCl 4 : 2-aminoterephthalic acid: acetic acid: N,N-dimethylamide molar ratio is 1:1:100:450, then add UiO-66-NH to the mixed solution 2 The functionalized multi-walled carbon nanotubes with a mass of 4 wt% of the material are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com