Ultra-microporous ionic polymer material and preparation method and application thereof

An ionic polymer, ultra-microporous technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of slow mass transfer, difficult recovery, high viscosity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Weigh 5g of 1,3,5-tris(bromomethyl)benzene and 4.35g of vinylimidazole, add them into 250mL of acetonitrile, mix and dissolve under stirring, and then heat to 50°C for 36 hours to react. The obtained product was filtered and washed with acetonitrile, and then vacuum-dried at 65°C for 24 hours to obtain a white solid, i.e. hyperbranched ionic liquid Ph-3MVIm-Br (Ph is a benzene ring group, 3 represents the number of hyperbranched, MVIm represents 1 - vinyl-3 methylene imidazolium cation, Br is an anion), its molecular structure is shown in formula (2-1), and the yield is about 80%.

[0064]

Embodiment 2

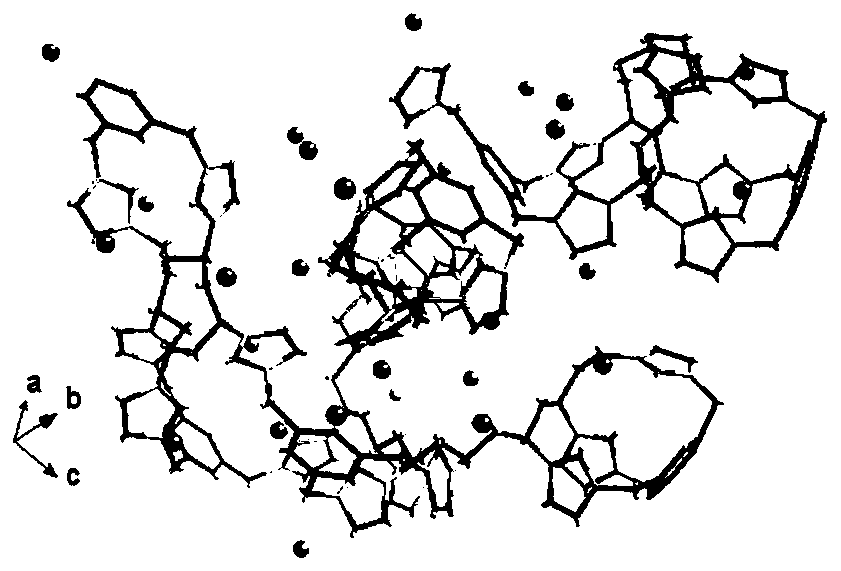

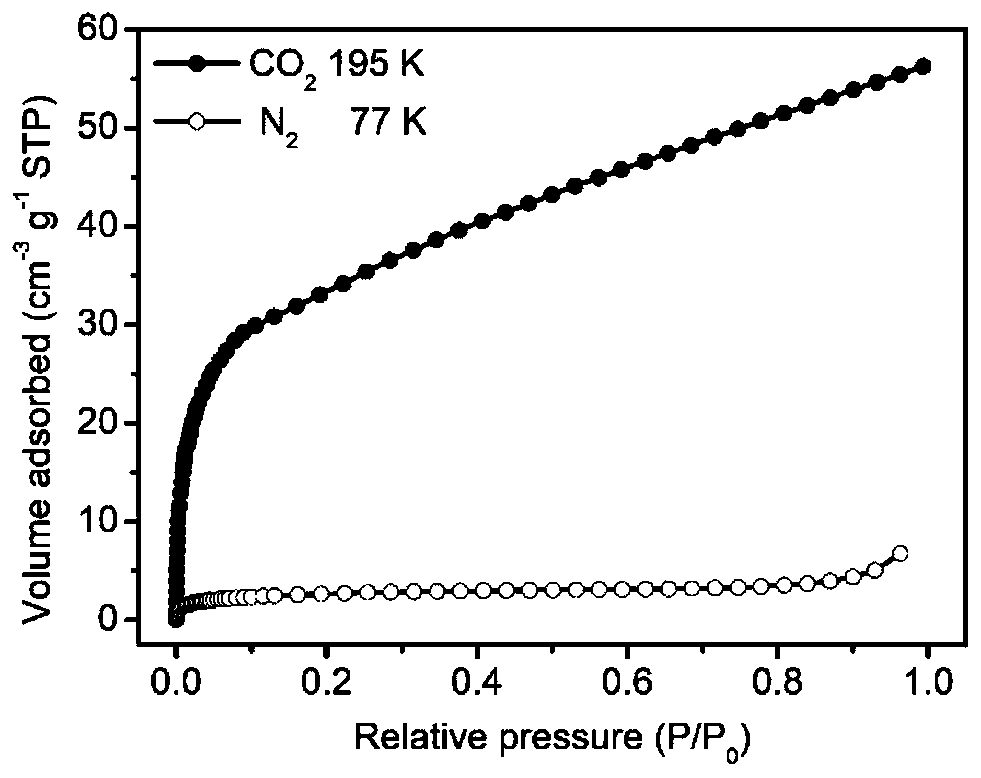

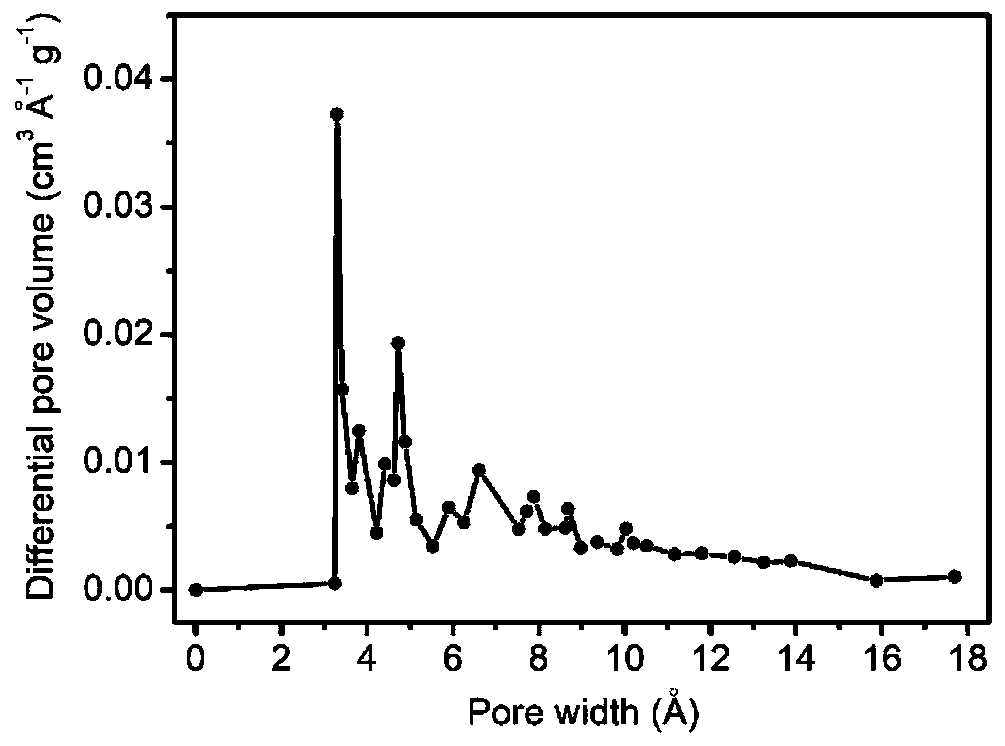

[0066] Weigh 1.0 g of the hyperbranched ionic liquid Ph-3MVIm-Br obtained in Example 1 and 0.03 g of azobisisobutyronitrile into a mixed solution of 10 mL of ethanol and 5 mL of water, mix and dissolve under stirring, and then heat to 70 ° C for 12 hours . The obtained product P(Ph-3MVIm-Br) was filtered, washed with water and methanol, and then dried under vacuum at 65° C. for 24 hours to obtain a white solid powder with a yield of about 85%. Such as figure 2 and image 3 As shown, the material in CO 2 (195K) as the medium, the measured Langmuir specific surface area is 244m 2 / g, the total pore volume is 0.104cm 3 / g, the aperture is Adsorbent P(Ph-3MVIm-Br) in N 2 (77K) as the medium, the specific surface area is only 10.0m 2 / g. This result indicates that P(Ph-3MVIm-Br) is an ultramicroporous material. Such as Figure 4 As shown, the thermogravimetric results show that the material has excellent thermal stability, and the thermal decomposition temperature is as...

Embodiment 3

[0072] Weigh 5g of 1,3,5-tris(chloromethyl)benzene and 6.95g of vinylimidazole, add them into 250mL of acetonitrile, mix and dissolve under stirring, and then heat to 50°C for 36 hours to react. The obtained product was filtered and washed with acetonitrile, and then vacuum-dried at 65° C. for 24 hours to obtain a white solid, namely hyperbranched ionic liquid Ph-3MVIm-Cl, with a yield of about 80%.

[0073] Weigh 1.0g hyperbranched ionic liquid Ph-3MVIm-Cl and 0.03g azobisisobutyronitrile into 10mL N,N-dimethylformamide and 5mL water mixed solution, mix and dissolve under stirring, then heat to 80 °C for 12 hours. The obtained product P(Ph-3MVIm-Cl) was filtered, washed with water and methanol, and then dried under vacuum at 65° C. for 24 hours to obtain a white solid powder with a yield of about 80%. CO under 195K 2 The results of the adsorption isotherm show that the Langmuir specific surface area of the material is 184m 2 / g, the total pore volume is 0.081cm 3 / g, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com