Desorption regeneration method of hydrophobic macroporous polymer adsorbent adsorbed with butanol

A polymer and hydrophobic technology, which is applied in the field of desorption and regeneration of butanol adsorption resin and resin, can solve the problems of high cost, large pollution and large consumption, and achieve low cost, low pollution and time saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

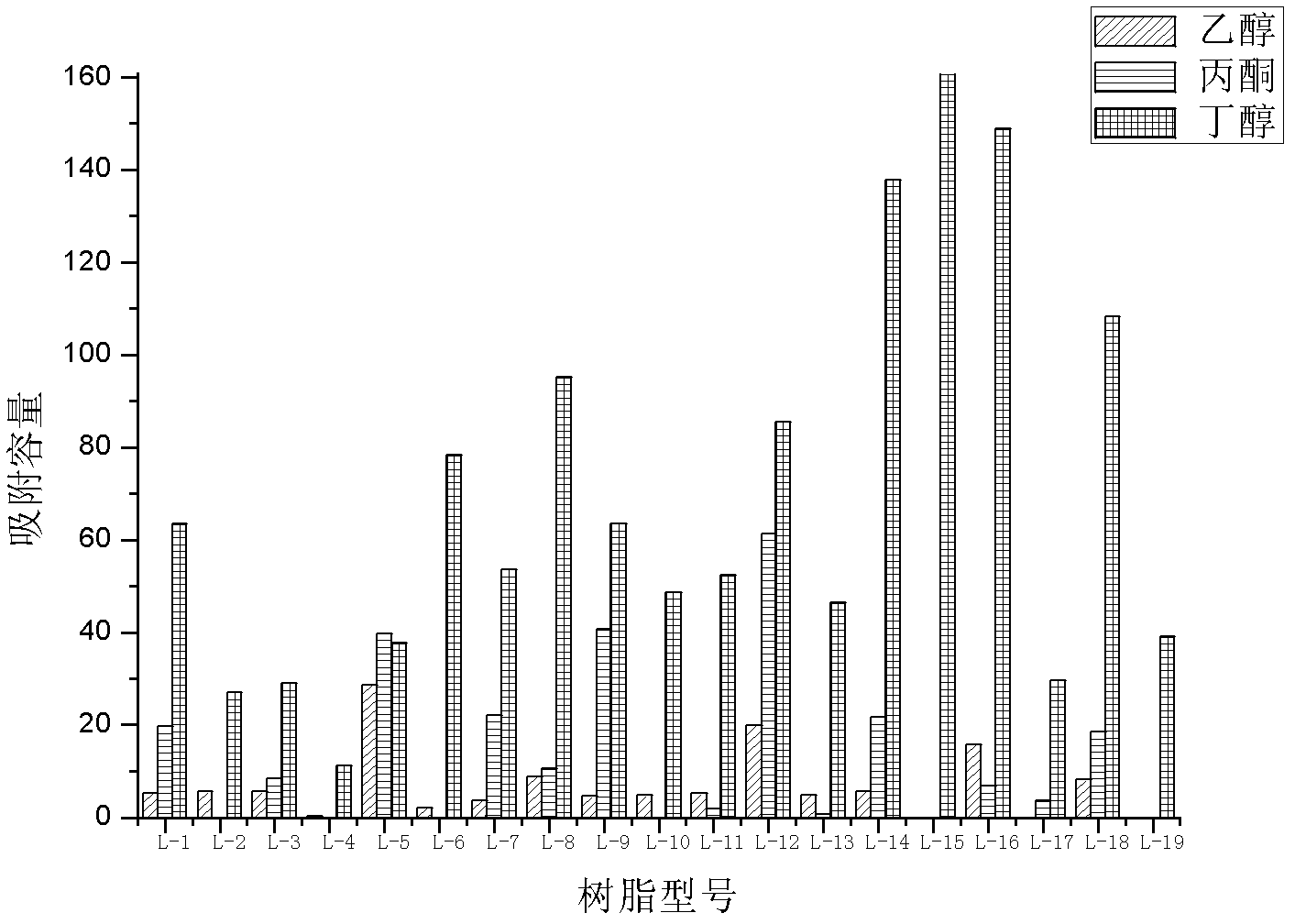

[0059] In this embodiment, the adsorption capacities of different hydrophobic macroporous polymer adsorbents to acetone, butanol, and ethanol in the mixed solution were measured, as follows.

[0060] Prepare a certain concentration of ABE mixed solution, wherein the concentration of butanol is 15g / L, the mass ratio of acetone, butanol and ethanol is 3:6:1, that is, the mass concentration ratio of the three components of ABE is 3:6:1, each adding 1 g of different macroporous polymer adsorbents ( figure 1 L in 1-19 , respectively Amberlite series, Diaion series, and D series resins), after the adsorption is saturated, use the GC method to calculate the adsorption capacity and separation factor of the macroporous polymer adsorbent for ABE.

[0061] The separation factor results are shown in Table 1.

[0062] Table 1

[0063]

[0064] The experimental results of the adsorption capacity are as follows: figure 1 shown. It can be seen from the figure that the Diaion series re...

Embodiment 2

[0068] The present embodiment adopts the L-15 macroporous adsorption resin (50g) in the embodiment 1 to carry out dynamic column adsorption, wherein, the butanol fermentation liquid containing acetone, butanol and ethanol is prepared as follows:

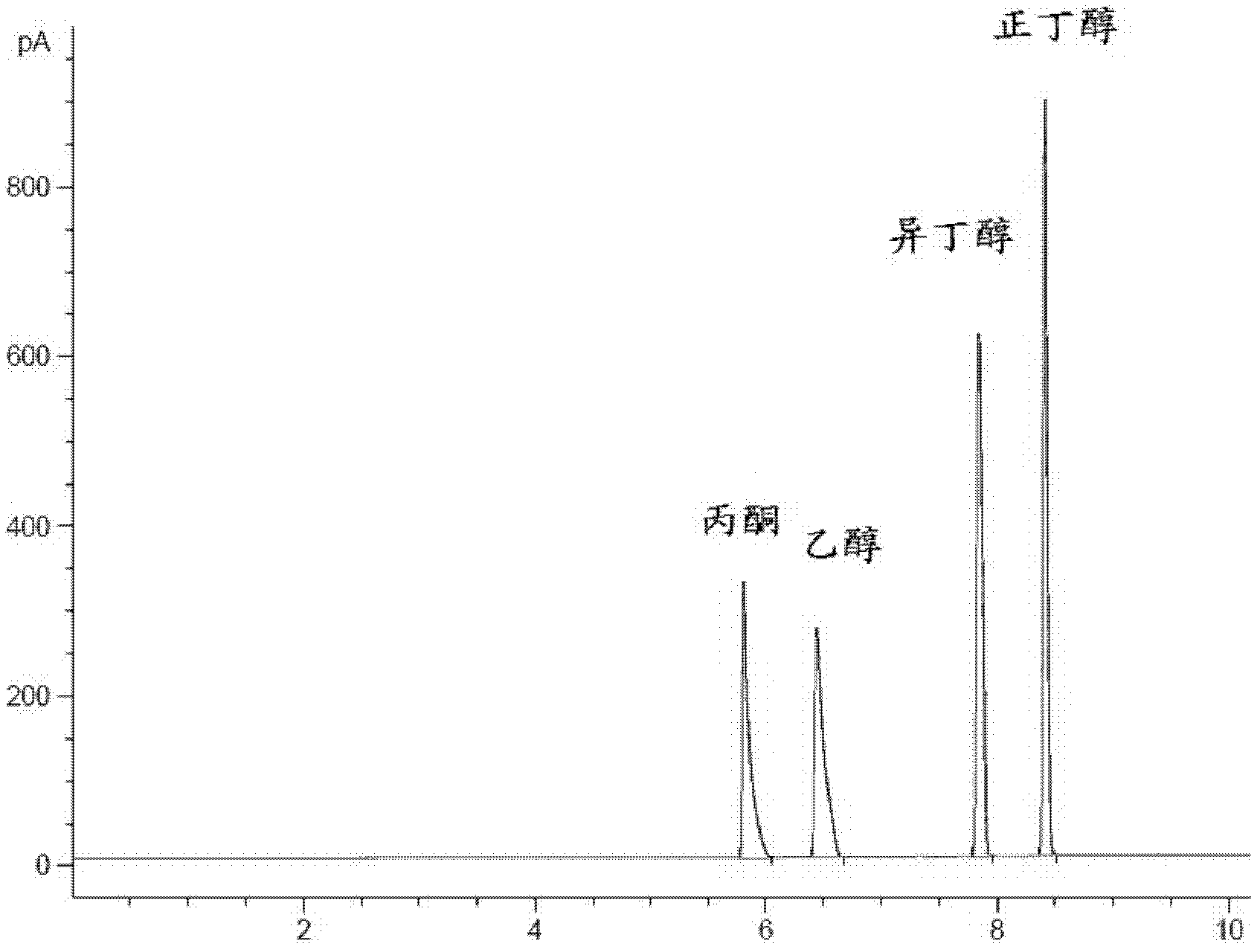

[0069] The Clostridium acetobutylicum strain was provided by the State Key Laboratory of Materials and Chemistry of Nanjing University of Technology, and anaerobic fermentation was carried out according to conventional methods in the field (fermentation went to the fermenter to blow nitrogen, maintain an anaerobic environment, and the temperature was 37 ° C), and obtained after 48 hours Its fermented liquid, through centrifugation, gets its supernatant (GC chromatogram sees image 3 ), record and contain acetone 4.56g / L, butanol 11.91g / L, ethanol 1.40g / L, butyric acid 0.60g / L, acetic acid 0.80g / L, glucose 10.0g / L in this fermented liquid supernatant. This embodiment and the following embodiments all adopt this fermentation liquid sup...

Embodiment 3

[0077] 50g of L-15 resin was loaded on a fixed bed, and 1L of butanol fermentation broth (containing 4.56g / L of acetone, 11.91g / L of butanol, 1.40g / L of ethanol, 0.60g / L of butyric acid, 0.80g / L of acetic acid, Glucose (10.0g / L) passed through the L-15 resin fixed bed at a flow rate of 1BV / h. After 10 hours, the volume of the detected absorptive solution was 0.96L, and contained acetone 4.26g / L, butanol 3.88g / L, ethanol 1.30g / L, butyric acid 0.56g / L, acetic acid 0.72g / L, glucose 9.6g / L.

[0078] Use 2BV of water to wash the adsorption bed (until it dries up). The volume of the washing liquid is 0.2L, and it contains 1.60g / L of acetone, 10.93g / L of butanol, 0.76g / L of ethanol, and 0.312g of butyric acid. g / L, acetic acid 0.294g / L, glucose 3.92g / L. According to the mass conservation of each component, use The formula calculates the saturated adsorption capacity of each component per gram of resin as follows: 3 mg of acetone, 120 mg of butanol, 0 mg of ethanol, 1 mg of butyric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com