Treatment method of waste water in hydroxybenzoic acid production

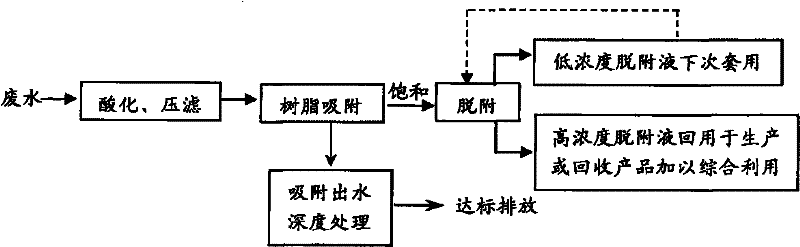

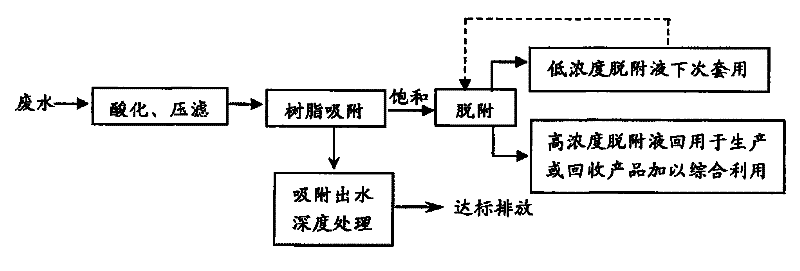

A technology for para-hydroxybenzoic acid and production wastewater, which is applied in the fields of natural water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve the problem of low treatment rate, inability to recycle chemical raw materials, and difficulty in treatment of production wastewater. Large and other problems, to achieve the effect of low operating cost, convenient industrialization implementation, and good wastewater treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present invention and not to limit the scope of the present invention. The implementation conditions used in the examples can be further adjusted according to the conditions of specific manufacturers, and the implementation conditions not indicated are usually the conditions in routine experiments.

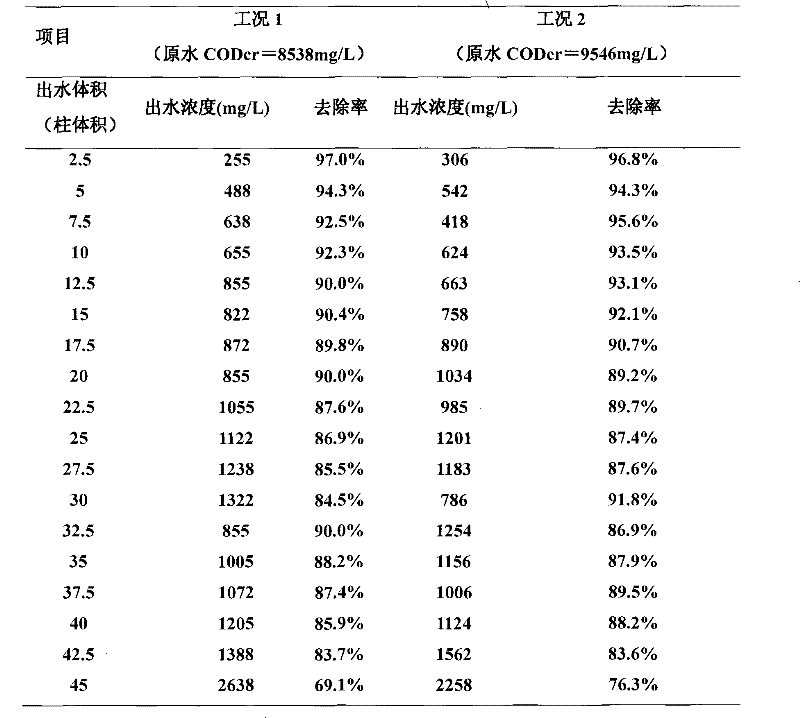

[0039] Example The treatment of waste water from the production of p-hydroxybenzoic acid in a chemical enterprise

[0040] (1) Synthesis of modified macroporous resin

[0041] The macroporous adsorption resin was synthesized by a two-step method. Including the preparation of macroporous microspheres, chloromethylation reaction and post-crosslinking reaction; wherein the preparation of macroporous microspheres uses a certain amount of styrene (St) monomer, divinylbenzene (DVB) crosslinking agent and toluene and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com