Method for treating waste water of H-acid production

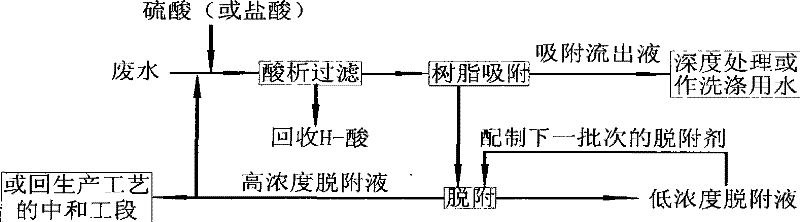

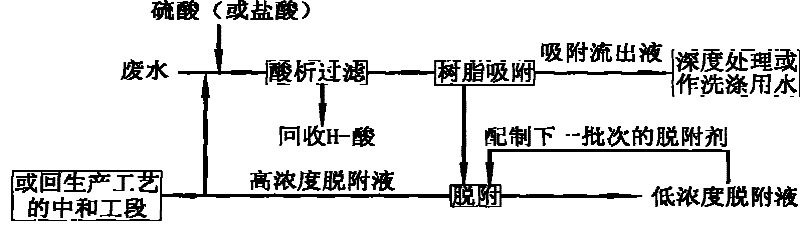

A technology for the production of waste water and treatment methods, applied in the directions of heating water/sewage treatment, neutralized water/sewage treatment, ion exchange water/sewage treatment, etc. Governance problems and other problems, to achieve the effects of comprehensive utilization, easy desorption and regeneration, and easy mastery of technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

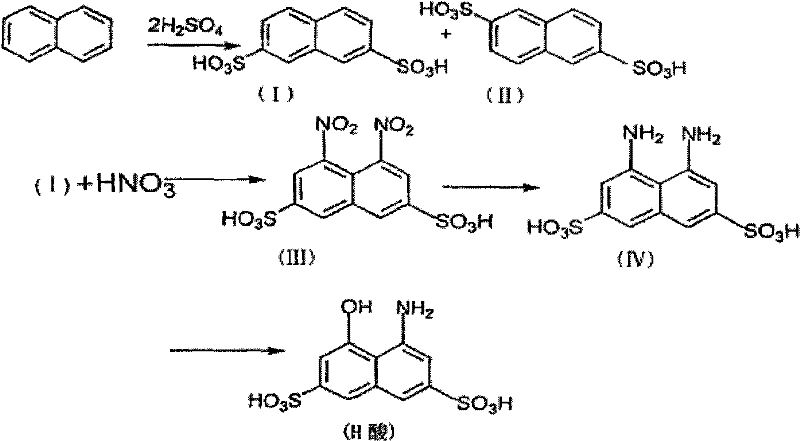

[0023] Below further illustrate the present invention by embodiment:

[0024] Pack 10mL of D301 macroporous weakly basic styrene-based anion exchange resin into a glass column (Φ20×300mm) with an insulating jacket. Take 70mL of H-acid production wastewater and cool it to room temperature, adjust the pH value to about 3, and pass through the resin column at room temperature (25°C) at a flow rate of 20mL / H. After neutralization treatment, it can reach the national secondary emission standard. The temperature of the D301 resin after adsorption is 55±5°C, and the desorbent combination is 1BV8%NaOH+2BV4%NaOH+2BVH 2 O 40mL for desorption regeneration, the flow rate is 10mL / H. The resin regenerated by desorption is reused. The desorption rate of 1-amino-8-naphthol-3,6-disulfonic acid (H-acid) was 96%. After the desorption solution (40mL) is distilled to 30mL, the recovered water can continue to be used as a desorption agent. After the distillation residual liquid is cooled, 1-am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com