Method and device for treating printing and dyeing wastewater by using macroporous adsorption resin

A technology of printing and dyeing wastewater and pore adsorption, which can be used in adsorption water/sewage treatment, textile industry wastewater treatment, water/sewage multi-stage treatment, etc. To achieve the effect of reducing investment and operating costs, simple process and operation, and significant processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

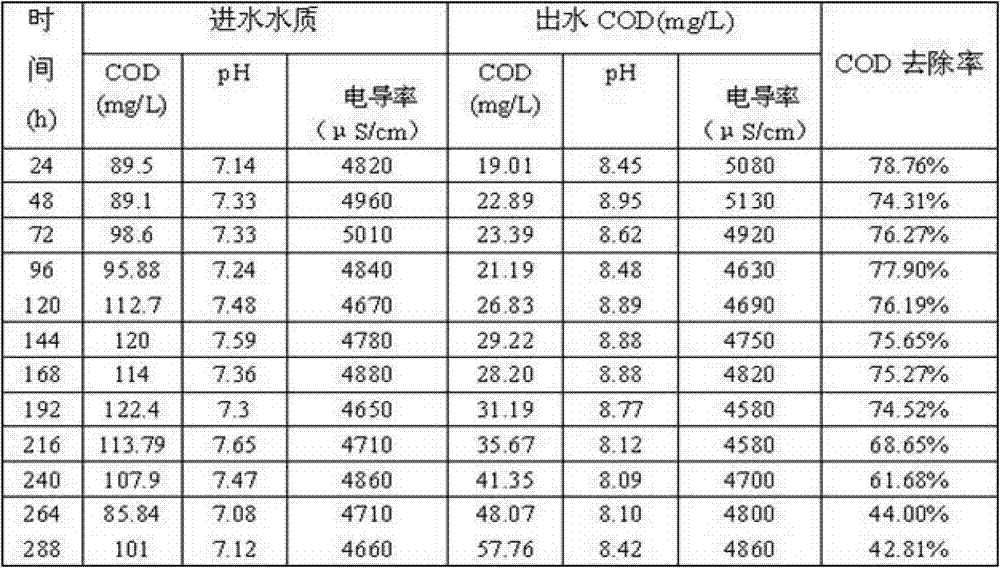

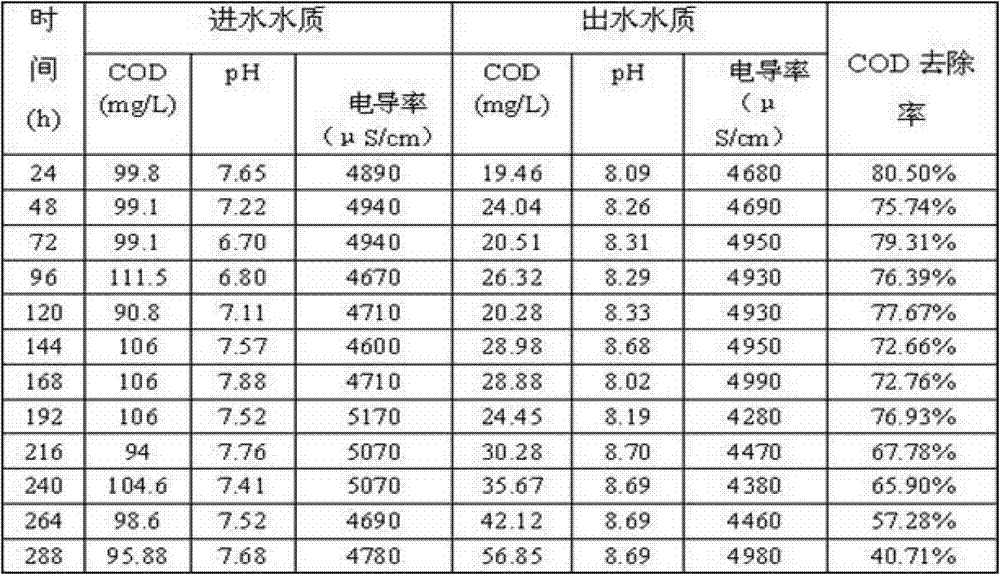

Examples

Embodiment Construction

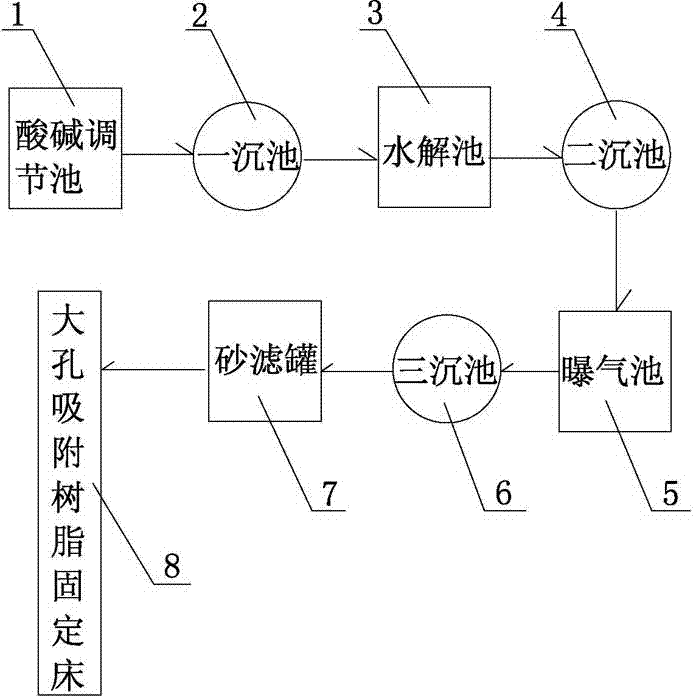

[0024] Please refer to the attached figure 1 As shown, the present invention is a device for treating printing and dyeing wastewater with macroporous adsorbent resin, which consists of an acid-base adjustment tank 1, a settling tank 2, a hydrolysis tank 3, a secondary settling tank 4, an aeration tank 5, A complete set of equipment composed of three sedimentation tanks 6, sand filter tank 7 and macroporous adsorption resin fixed bed 8.

[0025] Wherein, the macroporous adsorption resin fixed bed 8 is a hollow tempered glass column filled with a macroporous adsorption resin layer (not shown). The size of the tempered glass column is φ80mm×1300mm. The height of the macroporous adsorption resin layer is 1250mm, and its specific composition is styrene-divinylbenzene, the appearance is white, the particle diameter is 1-2mm, the water content is 68%-75%, and the wet true density is 1.05-1.10g / cm 3 , specific surface area 200~250m 2 / g, pore volume ≥0.68mL / g. The adsorption tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com