A method for adsorbing and separating sulfuric acid-containing gas

An adsorption separation and sulfuric acid technology, applied in the field of chemical engineering, can solve the problems of low pore volume and limited adsorption capacity, and achieve the effects of low cost, high separation selectivity and excellent adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

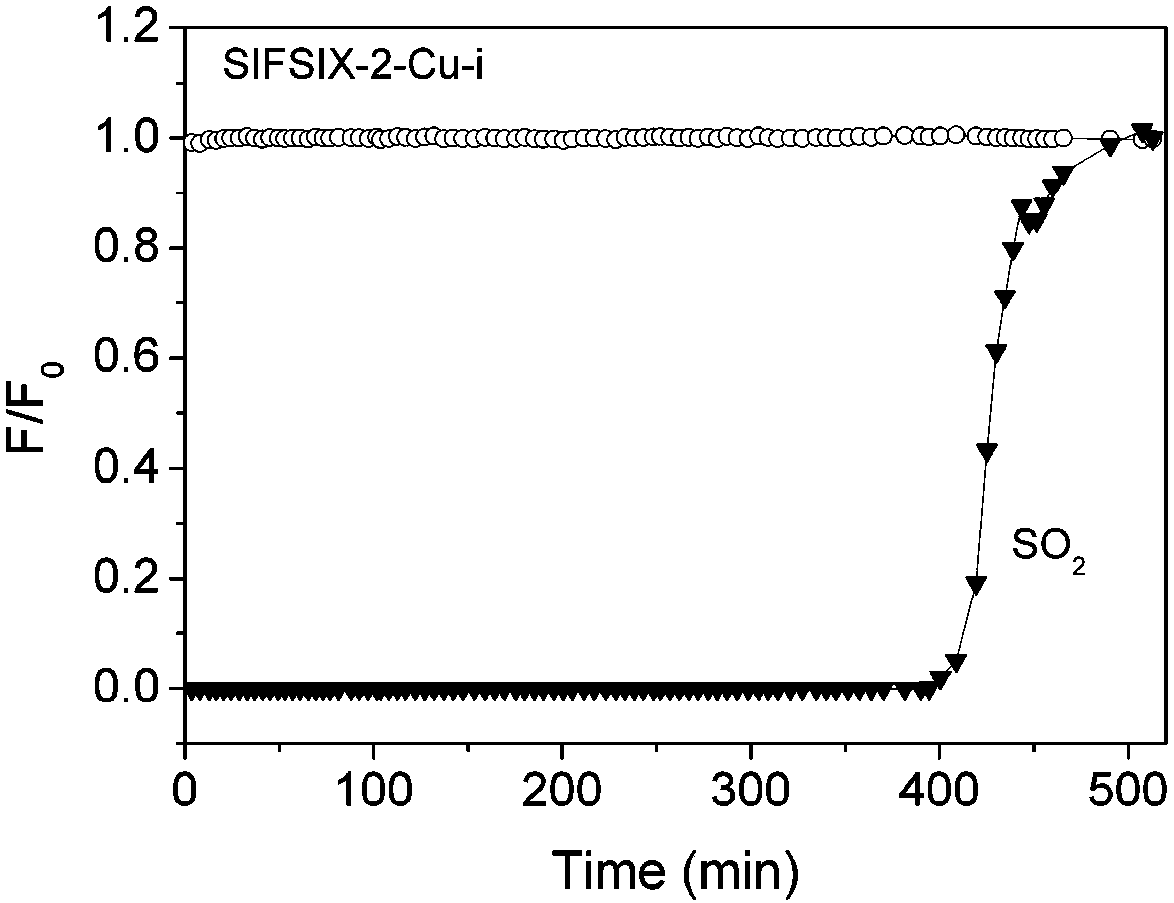

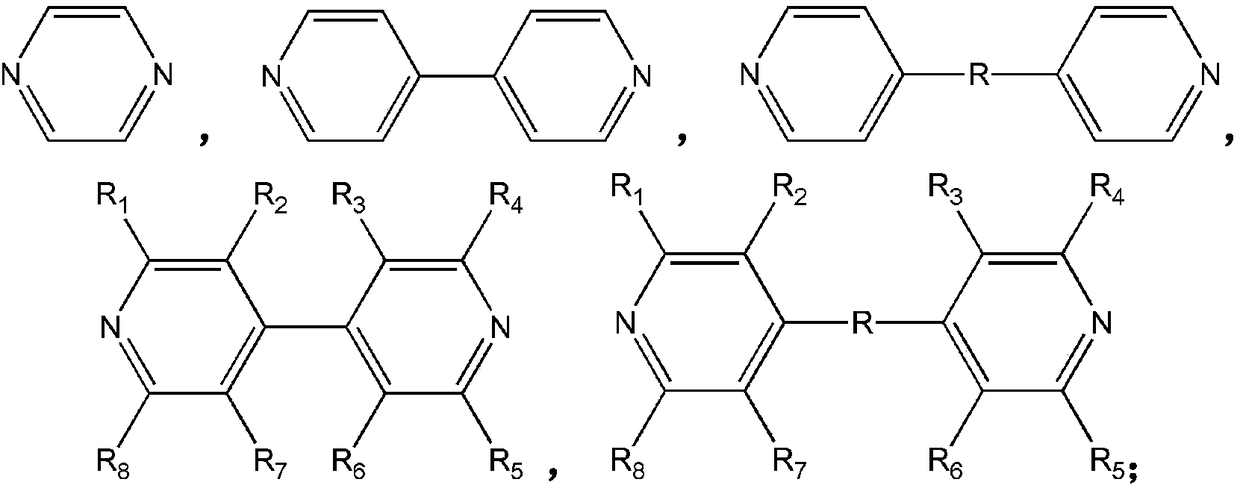

[0042] Weigh 46.44 mg of 4,4'-dipyridylacetylene (organic ligand L1) in 4 ml of methanol, weigh 89 mg of Cu(BF 4 ) 2 ·xH 2 O and 45.96 mg (NH 4 ) 2 SiF 6 (Inorganic anionic ligand L2) was dissolved in 4 ml of water, the above two solutions were mixed with stirring, and then heated to 60-100° C. to react for 12-36 hours. The obtained product SIFSIX-2-Cu-i (inorganic anion ligand is SiF 6 - ) was filtered, washed with methanol, and then activated. The adsorbent was packed into the adsorption column (inner diameter 4.6mm, length 50mm), at room temperature 25 ℃, 2000ppm SO 2 , 99.8%N 2 The mixed gas was passed into the adsorption column at 20ml / min, and the nitrogen with extremely low sulfur dioxide content (2 and 99.8%N 2 The breakthrough curve of the mixed gas on SIFSIX-2-Cu-i is as follows figure 1 shown.

Embodiment 2

[0044] Example 1 to obtain an adsorption column (inner diameter 4.6 mm, length 50 mm), at room temperature of 35 ° C, 10% SO 2 , 90% air mixture was passed into the adsorption column at 20ml / min, and the nitrogen with extremely low sulfur dioxide content (<10ppm) was obtained in the first 140min, and the adsorption was stopped. At 80°C, the sulfur dioxide gas was desorbed by vacuum.

Embodiment 3

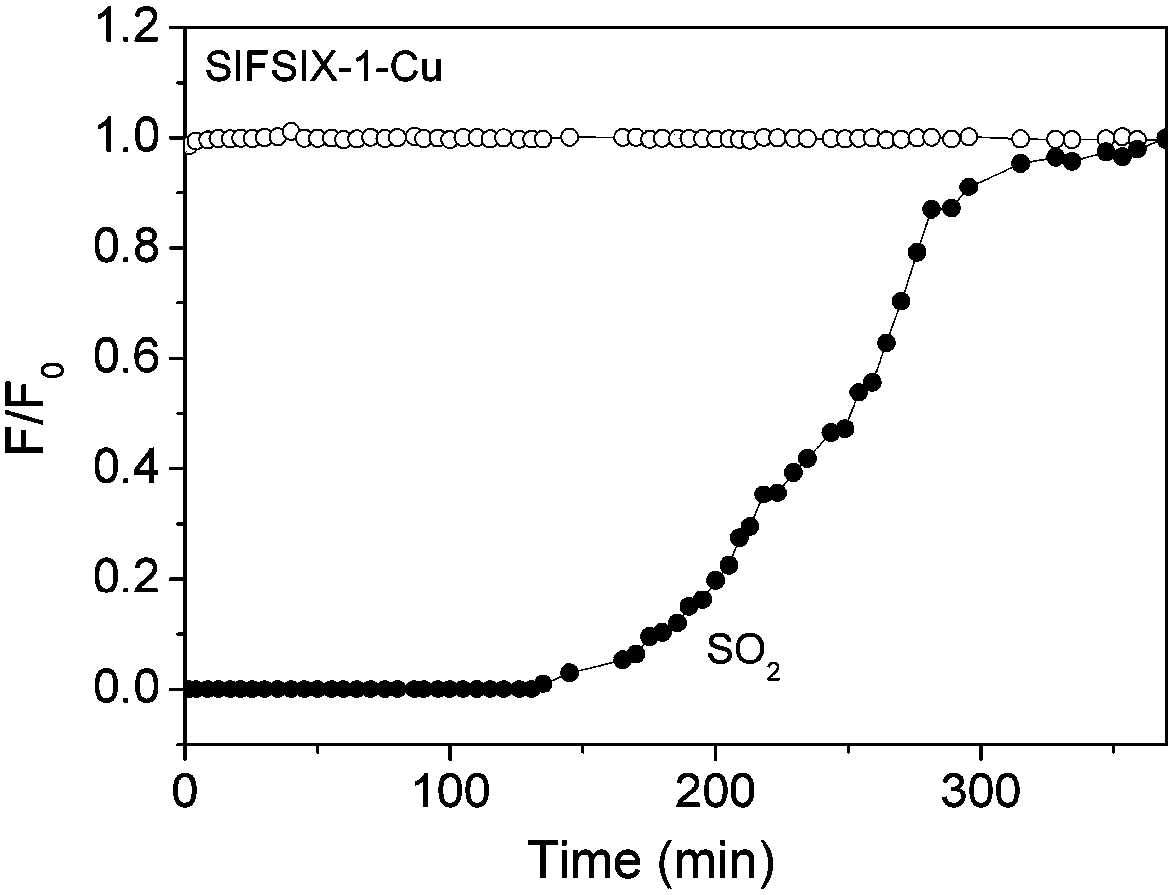

[0046] 0.35 g of 4,4'-bipyridine (organic ligand L1) was weighed and dissolved in ethylene glycol. Weigh 0.28 g of Cu (BF 4 ) 2 ·xH 2 O (metal ion M1) and 0.199 g (NH 4 ) 2 SiF 6 (inorganic anionic ligand L2) was dissolved in deionized water and added to a solution of 4,4'-bipyridine glycol. The reaction was stirred at below 100°C for 2-8 hours. The purple powder product SIFSIX-1-Cu (the inorganic anion ligand is SiF 6 - ) filtered and then activated. The adsorbent was packed into the adsorption column (inner diameter 4.6mm, length 50mm), at room temperature 25 ℃, 2000ppm SO 2 , 99.8% methane gas mixture was passed into the adsorption column at 20ml / min, and the nitrogen with extremely low sulfur dioxide content (2 and 99.8%N 2 The penetration curve on SIFSIX-1-Cu is as figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com