A kind of polyvinyl alcohol film with diene compound as crosslinking agent and preparation method thereof

A diene compound, polyvinyl alcohol technology, applied in the field of membrane separation, can solve problems such as limiting the application range of PVA, achieve high permeation flux and separation factor, ensure hydrophilicity, and be easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

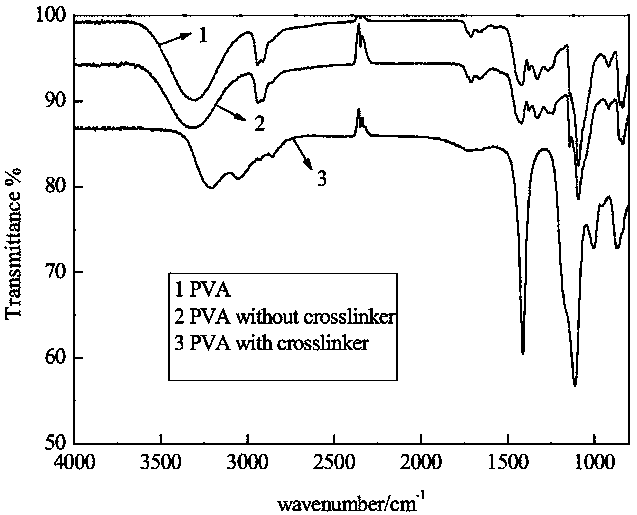

Image

Examples

Embodiment 1

[0029] A kind of diene compound is used as crosslinking agent to prepare polyvinyl alcohol pervaporation membrane, comprises the following steps, and described formula ratio is by weight:

[0030] (1) Take 5 parts of PVA AH-26 (molecular weight 114400, degree of alcoholysis 97-98.8%), 100 parts of deionized water, stir at 90°C for 6 hours, let stand for defoaming, and cool to room temperature.

[0031] (2) Add 1 part of initiator ammonium persulfate and 0.3 part of cross-linking agent N'N-methylenebisacrylamide into the PVA aqueous solution, and stir at room temperature for 6 hours to obtain a casting solution.

[0032] (3) Coat the prepared casting solution on the polyacrylonitrile base film with a scraper to a thickness of 10 μm.

[0033] (4) Put the above-scraped film into an oven at 80°C for heat treatment for 2 hours to obtain a PVA pervaporation film.

[0034] Using the pervaporation membrane separation device, the cross-linked PVA / PAN pervaporation membrane prepared in...

Embodiment 2

[0039] Preparing a polyvinyl alcohol pervaporation membrane with a diene compound as a crosslinking agent comprises the following steps, and the formula ratio is by weight:

[0040] (1) Take 5 parts of PVA AH-26 (molecular weight 114400, degree of alcoholysis 97-98.8%), 100 parts of deionized water, stir at 90°C for 6 hours, let stand for defoaming, and cool to room temperature.

[0041] (2) Add 1.5 parts of initiator potassium persulfate and 0.2 parts of cross-linking agent N'N-methylenebisacrylamide into the PVA aqueous solution, stir at room temperature for 6 hours to obtain a casting solution.

[0042] (3) Coat the prepared casting solution on the polyacrylonitrile base film with a scraper to a thickness of 10 μm.

[0043] (4) Put the above-scraped film into an oven at 80°C for heat treatment for 2 hours to obtain a PVA pervaporation film.

[0044] Using the pervaporation membrane separation device, the cross-linked PVA / PAN pervaporation membrane prepared in this example ...

Embodiment 3

[0049] Preparing a polyvinyl alcohol pervaporation membrane with a diene compound as a crosslinking agent comprises the following steps, and the formula ratio is by weight:

[0050] (1) Take 5 parts of PVA-1799 (molecular weight 82000, degree of alcoholysis 99.8-100%), 100 parts of deionized water, stir at 90°C for 6 hours, let stand for defoaming, and cool to room temperature.

[0051] (2) Add 2 parts of initiator sodium persulfate and 0.3 parts of crosslinking agent N'N-methylenebisacrylamide into the PVA aqueous solution, stir at room temperature for 6 hours, and obtain a casting solution.

[0052] (3) Coat the prepared casting solution on the polysulfone base film with a spatula, with a thickness of 8 μm.

[0053] (4) Put the above-scraped film into an oven at 80°C for heat treatment for 4 hours to obtain a PVA pervaporation film.

[0054] Using the pervaporation membrane separation device, the cross-linked PVA / PS pervaporation membrane prepared in this example was subjec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| alcoholysis degree | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com