Synchronous electricity generation and sewage purification device utilizing steel slag as positive electrode

A sewage purification and steel slag technology, applied in water/sewage treatment, biological water/sewage treatment, water/sewage multi-stage treatment, etc., to achieve the effects of reducing internal resistance, strengthening sewage purification ability, and improving electron transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

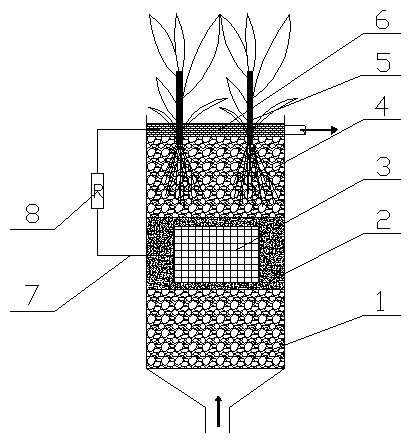

[0031] Such as figure 1 As shown, a device for synchronous power generation and sewage purification using steel slag as an anode uses a cylindrical PVC pipe (H=70cm, D=15cm) as an upward vertical flow artificial wetland, and the upward vertical flow artificial wetland includes bottom non- The conductive filler layer 1, the steel slag anode layer 2, the current collector 3, the upper non-conductive filler layer 4, the cathode layer 6, the wire 7, the resistance box 8 and the wetland plants 5, and the bottom non-conductors are arranged sequentially from bottom to top in the vertical flow constructed wetland. Conductive filler layer 1, steel slag anode layer 2, upper non-conductive filler layer 4 and cathode layer 6, current collector 3 is embedded in steel slag anode layer 2, current collector 3 and cathode layer 6 are connected by wire 7 and resistance box 8 respectively In a closed loop, wetland plants 5 are planted in the upper non-conductive filler layer 4 through the cathod...

Embodiment 2

[0037] A device for synchronous power generation and sewage purification using steel slag as an anode, using a cylindrical PVC pipe (H=70cm, D=15cm) as an upward vertical flow artificial wetland, and the upward vertical flow artificial wetland includes a bottom non-conductive filler layer 1. Steel slag anode layer 2, upper non-conductive filler layer 4, cathode layer 6, wire 7, resistance box 8 and wetland plants 5, bottom non-conductive filler layer 1, steel slag anode layer are arranged in sequence from bottom to top in the vertical flow artificial wetland 2. The upper non-conductive filler layer 4 and the cathode layer 6, the current collector 3 is buried in the steel slag anode layer 2, the current collector 3 and the cathode layer 6 are respectively connected to the resistance box 8 through the wire 7 to form a closed circuit, and the wetland plants 5 pass through The cathode layer 6 is planted in the upper non-conductive filler layer 4 , the water inlet pipe is arranged a...

Embodiment 3

[0043] A device for synchronous power generation and sewage purification using steel slag as an anode, using a cylindrical PVC pipe (H=70cm, D=15cm) as an upward vertical flow artificial wetland, and the upward vertical flow artificial wetland includes a bottom non-conductive filler layer 1. Steel slag anode layer 2, upper non-conductive filler layer 4, cathode layer 6, wire 7, resistance box 8 and wetland plants 5, bottom non-conductive filler layer 1, steel slag anode layer are arranged in sequence from bottom to top in the vertical flow artificial wetland 2. The upper non-conductive filler layer 4 and the cathode layer 6, the current collector 3 is buried in the steel slag anode layer 2, the current collector 3 and the cathode layer 6 are respectively connected to the resistance box 8 through the wire 7 to form a closed circuit, and the wetland plants 5 pass through The cathode layer 6 is planted in the upper non-conductive filler layer 4 , the water inlet pipe is arranged a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com