Method of water disposal

A water treatment and raw water technology, applied in water/sewage treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of inequal sludge treatment, disturbed swirl flow, dissolved oxygen Insufficient and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

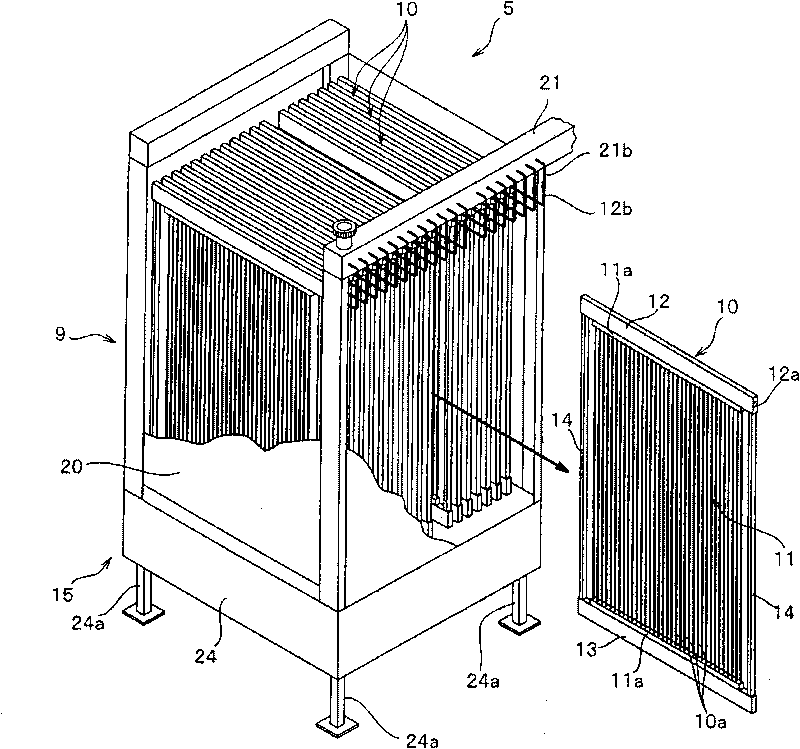

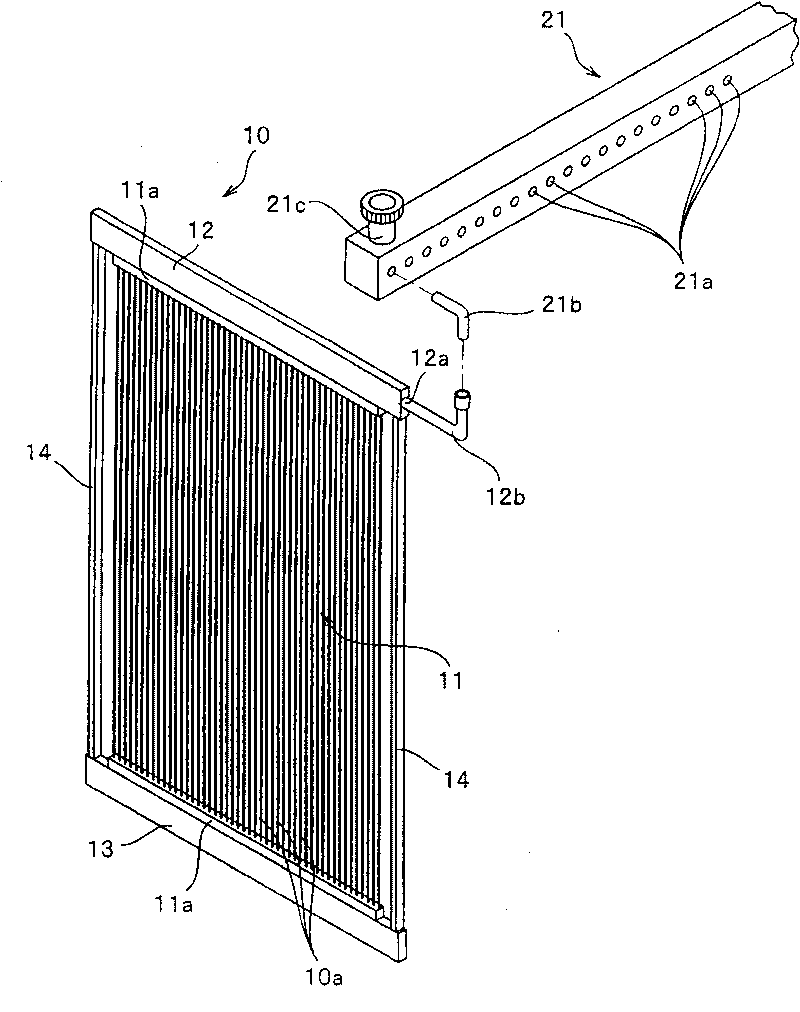

[0089] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

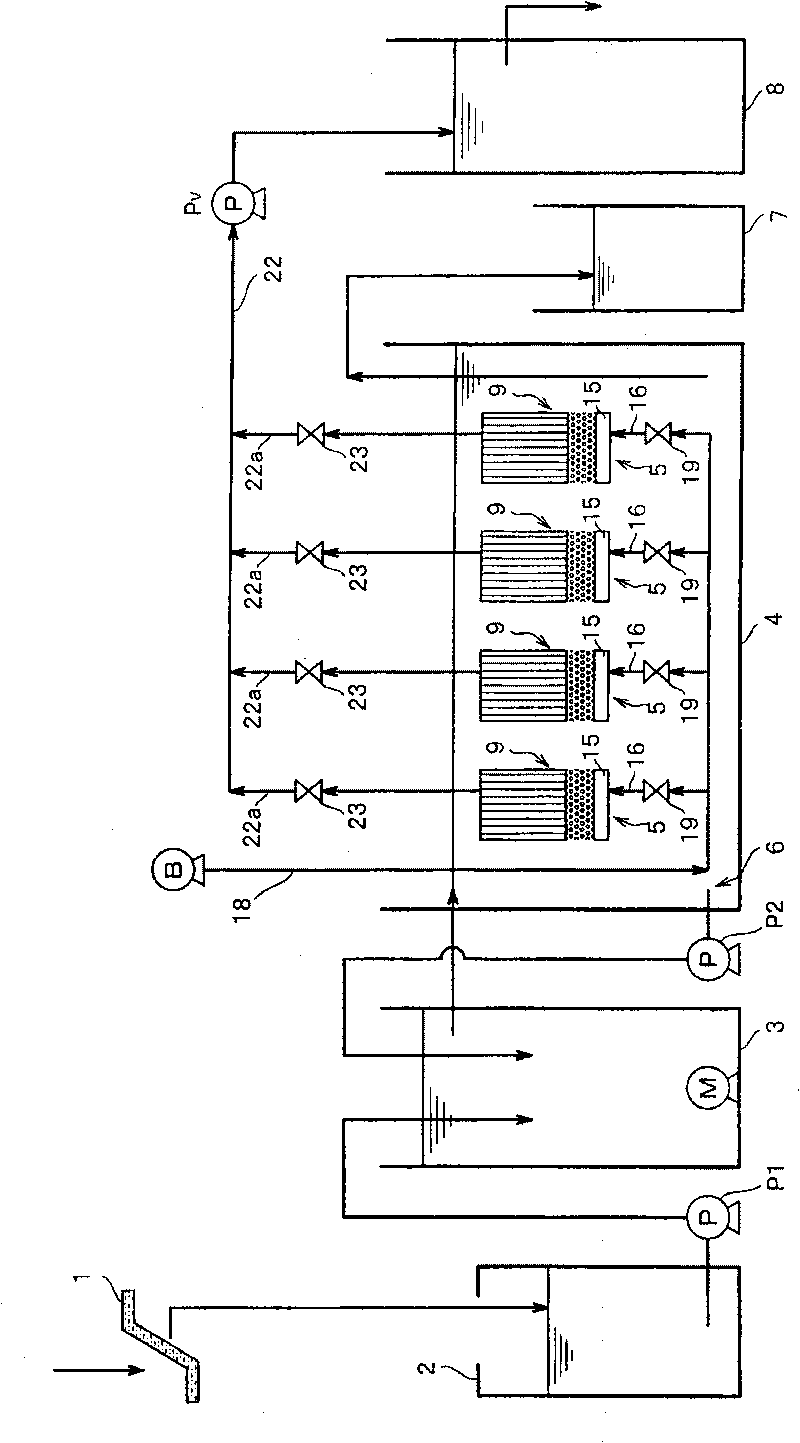

[0090] figure 1 A schematic structure of a typical treatment apparatus for carrying out the water treatment method of the present invention is shown.

[0091] According to this water treatment device, waste water (raw water) from which relatively large solids have been removed by the fine-pore filter 1 is introduced into the raw water adjustment tank 2 . Here, the liquid level is measured by a liquid level measuring device not shown, and the first liquid feeding pump P1 is intermittently operated to adjust the liquid level height in the tank to be within a predetermined range. After the raw water transported by the first liquid delivery pump P1 is introduced into the anaerobic tank 3 , the raw water overflowing from the anaerobic tank 3 flows into the adjacent aeration tank 4 . A plurality of membrane filtration units 5 are immersed in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com